How important is AI for TRUMPF?

We use artificial intelligence to tackle abstractly formulated tasks. The advantage is that it works independently without us having to program each individual step. It easily identifies patterns in data and processes that we would have struggled to detect or even overlooked completely in the past. In future, AI will ensure that complex technical systems remain manageable. All this will ultimately make manufacturing more efficient and improve our solutions and products, ensuring that we keep our competitive edge.

What stage have we reached so far at TRUMPF?

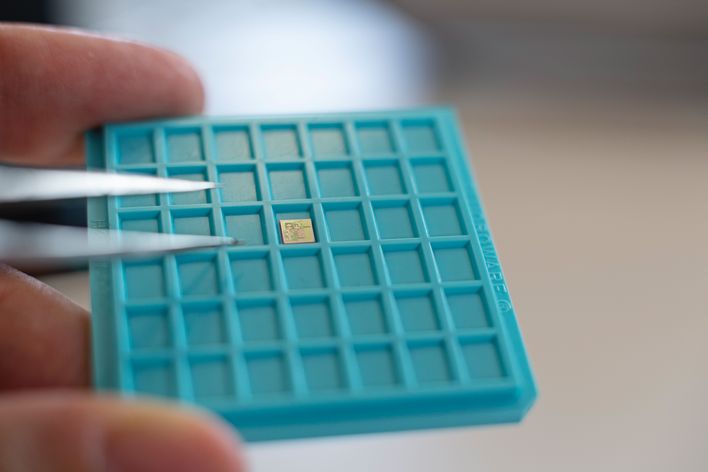

We are already researching and working with artificial intelligence. AI is helping us with quality control, and our colleagues are developing an AI solution that will give service technicians suggestions on what repairs they need to make. We also have representatives embedded in all the key associations, organizations and committees that deal with this topic. Working with partners is absolutely essential: only through collaborative efforts and projects can we develop the uniform standards and open platforms that will lay the foundations for widespread deployment of AI.

How will AI change the future of TRUMPF?

The deployment of AI opens up new fields of activity in areas such as sensor systems and testing. We have to select and prepare the right data before AI can use it, so humans still have an indispensable role to play in making AI work. In future, our jobs are likely to shift toward planning and supporting processes and interpreting the results. AI will release us from some of the more physically demanding and monotonous routine tasks.

Thomas Schneider is responsible for LifeCycle Engineering/Product Quality at TRUMPF in Ditzingen and is in charge of the development of production platforms in the Machine Tool Business Division.