In October 2019, a team of researchers at the University of California were working on a particularly tricky arithmetic task. With Google and a quantum computer on board, they solved the problem in less than 200 seconds. Publishing their results in the journal Nature, the scientists pointed out that a conventional supercomputer would have taken 10,000 years to complete the same computation. U.S. computer giant IBM quickly contradicted this, noting that its latest supercomputer could have solved the problem in just two-and-a-half days. Whatever the case, the quantum computer was faster. But how does this miracle machine work?

Bits and qubits

One of the main differences to conventional computing is that a quantum computer can be in many states at the same time. Today’s computers use binary digits, or bits, which can assume just two states: 0 or 1. Quantum computers use quantum bits, or qubits, to perform their calculations. Qubits can assume the states 0 and 1 simultaneously – and can also be in all the states in between. That makes quantum computers far more powerful than conventional ones.

Puzzling out sheet metal parts

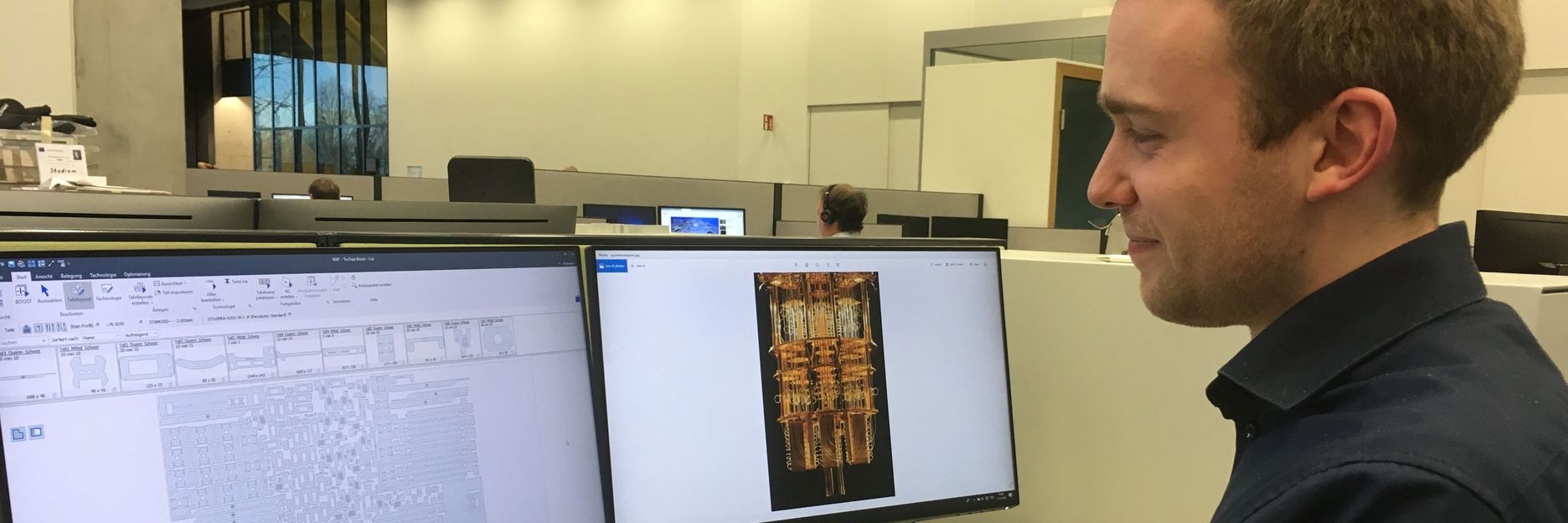

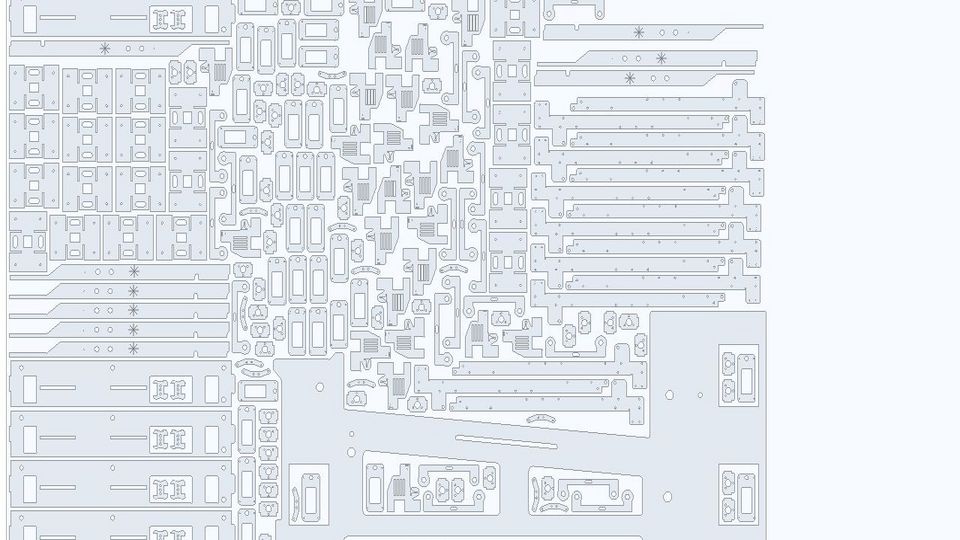

Quantum computers could help with the complex computations of sheet metal fabrication. One of the trickiest dilemmas for fabricators is known as “nesting.”The idea is to get the greatest possible number of parts out of a single sheet of metal in order to save material. Fabricators can use specialist software to help with nesting, but this only takes into account the shape of each part. It ignores other important factors, such as how to cut parts without causing them to tilt. Many operators therefore opt to carry out manual nesting for more complex jobs. They place the parts on the metal sheet like a giant jigsaw puzzle, drawing on their experience and the strategies they have learned over the years. Asking a computer to weigh up all the different factors would mean waiting hours, or even days, for the result (see photo above: TRUMPF employee Frederick Struckmeier at the classic “nesting” on the computer). Conventional computers are simply not powerful enough to come up with the perfect nesting solution at the push of a button. But it’s a different story for a quantum computer.

In "nesting", the employee places the components on the sheet metal plate virtually on the computer, like a puzzle. The aim is to get as many parts out of the sheet as necessary. The machine then uses a laser to cut the parts out.

© TRUMPF

The importance of scheduling

Nesting is complicated enough but deciding when to schedule each job makes things even harder. To create the perfect schedule, you need to know how urgent each job is, which machines are free, and which material and sheet thickness the customer wants. Combining all these points makes the calculations even more complex, pushing them out of reach of today’s computers. But a quantum computer would have no trouble tackling these kinds of computations – provided that researchers keep making the kind of progress we’ve seen so far.

A quantum computer for worldwide use

In January 2020, TRUMPF will be embarking on a research project that aims to make quantum computers industry-ready. Together with 14 partners, the company is taking part in the PlanQK project, funded to the tune of 10.8 million euros over a three-year period by the Federal Ministry for Economic Affairs and Energy (BMWi). It aims to create a cloud platform that will enable companies all over the world to make joint use of a quantum computer.

Calculating solutions in real time

TRUMPF’s job is to format nesting and scheduling data for a quantum computer to calculate the best solution for both in real time. TRUMPF project manager Jens Ottnad estimates it will take another ten to 15 years before the necessary computing power is commercially available. But the project partners are keen to get a head start so that Germany can exploit the technologies to the full when the time comes.