Actually, Fischer Maschinenbau GmbH was "only" looking for a processing software, recalls owner Ralf Fischer, who runs the company together with his brother Bernd Fischer. The family business in Erkheim, Bavaria, specializes in components for system engineering, machine and vehicle construction. The 25 employees are committed to precision, speed and flexibility for their customers. Fischer made the same demands on the software - but he didn't find what he was looking for: "What was available on the market was extensive, complicated and had nothing to do with laser cutting and bending," he said.

Until Fischer came across TecZone Bend. The TRUMPF program simulates bends in 3D and automatically checks feasibility. "Fascinating!" exclaimed Fischer. "We immediately said, ok, we need that!" However, it also quickly became clear that "to take full advantage of the program, we'd need a TRUMPF press brake to do it." Fischer then invested in the TruBend 5230 - and has not regretted it. The three options - Part Indicator, ACB Laser and ACB Wireless – all played a decisive role here.

Minimizing scrap with the Part Indicator

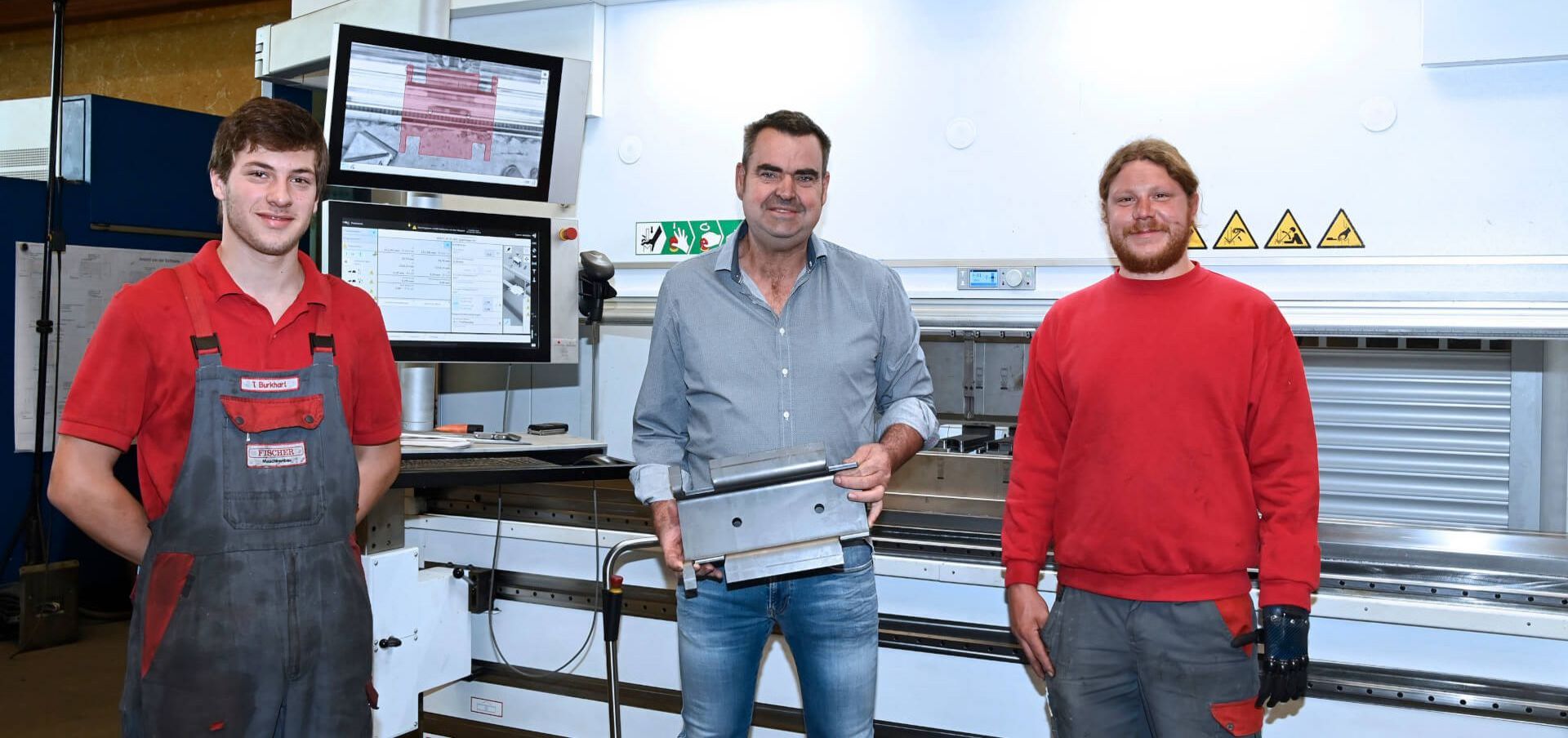

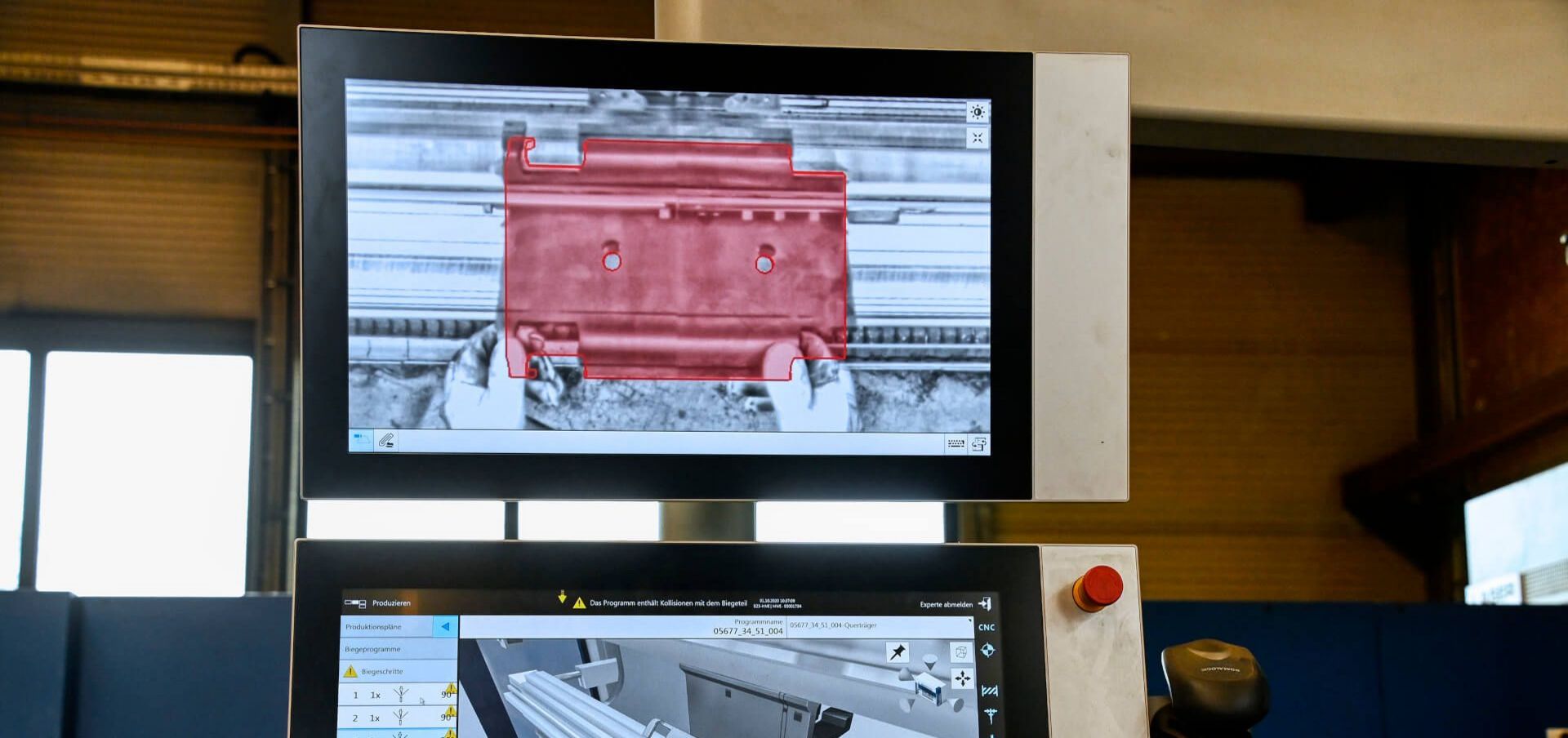

The Part Indicator shows on the screen how the bending part must be positioned and, with the help of the Contour Check function, signals the optimum position with easy-to-understand traffic light colors. Right from the start, the system brings a number of advantages, first and foremost the reduction of scrap. "We have a great many parts that are the same in terms of cutting but are mirrored," explains Fischer. "The big plus of the Part Indicator is that you just can't make bending mistakes anymore!" Two cameras simultaneously check how the part was positioned, so that the operator can then see on the screen whether the insertion position is right or not and where the error lies.

Since then, Fischer Maschinenbau has minimized scrap in its sheet metal processing and has increased speed. "In the past, we often cut a test strip or generally one or two more parts so that we had one good part," Fischer says. "Now we don't really do that at all." What's more, even employees who are untrained in this particular area can hardly make any mistakes.

High accuracy - without retooling

With the Part Indicator, the part was positioned accurately - so far, so good. But what about the required angle? Numerous factors can influence its accuracy, including the material or springback. That's why the TruBend that Fischer chose has the ACB Laser and ACB Wireless options. "ACB" here stands for "Automatically Controlled Bending."

"The ACB Laser works with very high accuracy," says Fischer. Whether thin or thick sheet, a batch size of 1 or series parts, "If you load the program, the process runs." The operator uses the ACB Laser optical system for angle measurement without having to retool. A duo of laser and camera each travel independently along the desired bend. The laser projects a corresponding line onto the bending part, and the camera recognizes the line and calculates the angle of the part in real time.

"Unbeatable Combination"

The ACB Wireless is as user-friendly as the ACB Laser: It corrects angles with the help of two tactile disks integrated in the upper tool. When bending, these sensing discs touch the inside of the bending part. In doing so, they work together with sensors to measure the exact angle electronically and ensure that it is correct. All this happens wirelessly.

Whether the Fischer customer is a small welding shop needing just one part or a well-known systems engineering company with series production requirements, the clever assistance systems and the TecZone Bend bending program make the operators’ work easy. "The combination of software, machine and the three options for ensuring the accuracy of a good part is almost unbeatable," says Fischer, summing up.