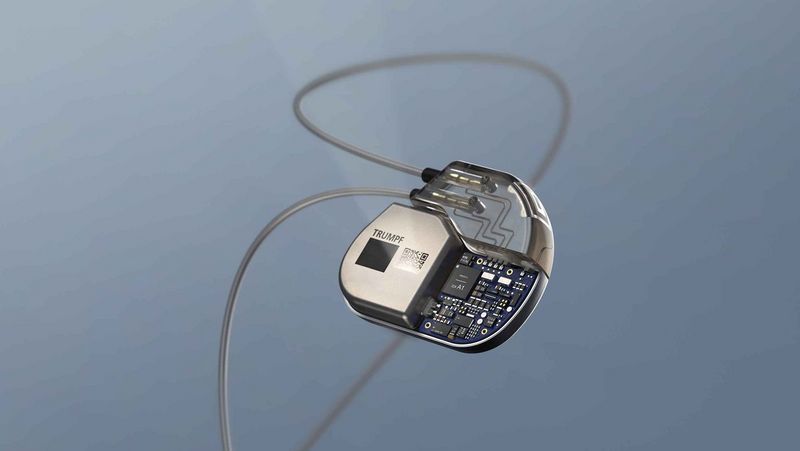

In den letzten Jahrzehnten hat die Lasertechnologie nicht nur verändert, wie Mediziner ihre Patienten behandeln. Sie revolutionierte auch die Art und Weise, wie Unternehmen Medizinprodukte herstellen. Implantierbare Herzschrittmacher, Ballonkatheter oder Stents – lebensrettende medizinische Produkte wären ohne moderne Lasertechnik nicht vorstellbar. Mit Lasersystemen können Hersteller von Medizinprodukten und medizinischen Komponenten selbst kleinste Bauteile präzise, flexibel und steril bearbeiten. Außerdem ermöglichen sie den Einsatz von fortschrittlichen und biokompatiblen Materialien. Eingriffe werden für den Patienten damit verträglicher und Behandlungsergebnisse verbessert.

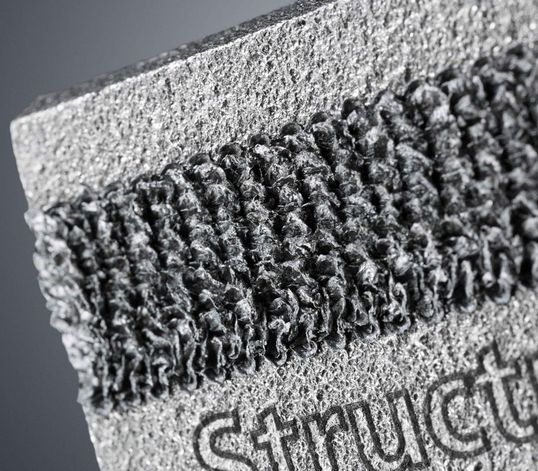

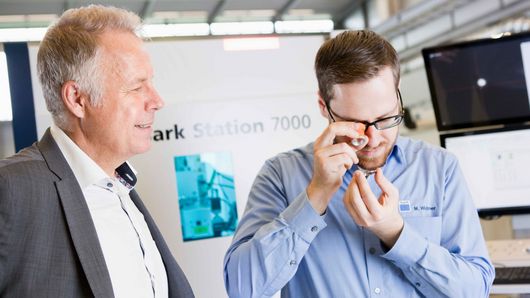

Natürlich erfüllen Laser auch die hohen Ansprüche, welche die stark regulierte Branche an die Entwicklung medizinischer Geräte stellt. Sie schaffen Produkte von gleichbleibend makelloser Qualität. Dabei sind Laser vielseitig einsetzbar: Sei es zum Schweißen, Schneiden, Kennzeichnen und Strukturieren oder zum Entfernen von Beschichtungen. Setzen auch Sie auf die Laserbearbeitung und damit auf maximale Prozesssicherheit, Genauigkeit und Qualität.