Challenges

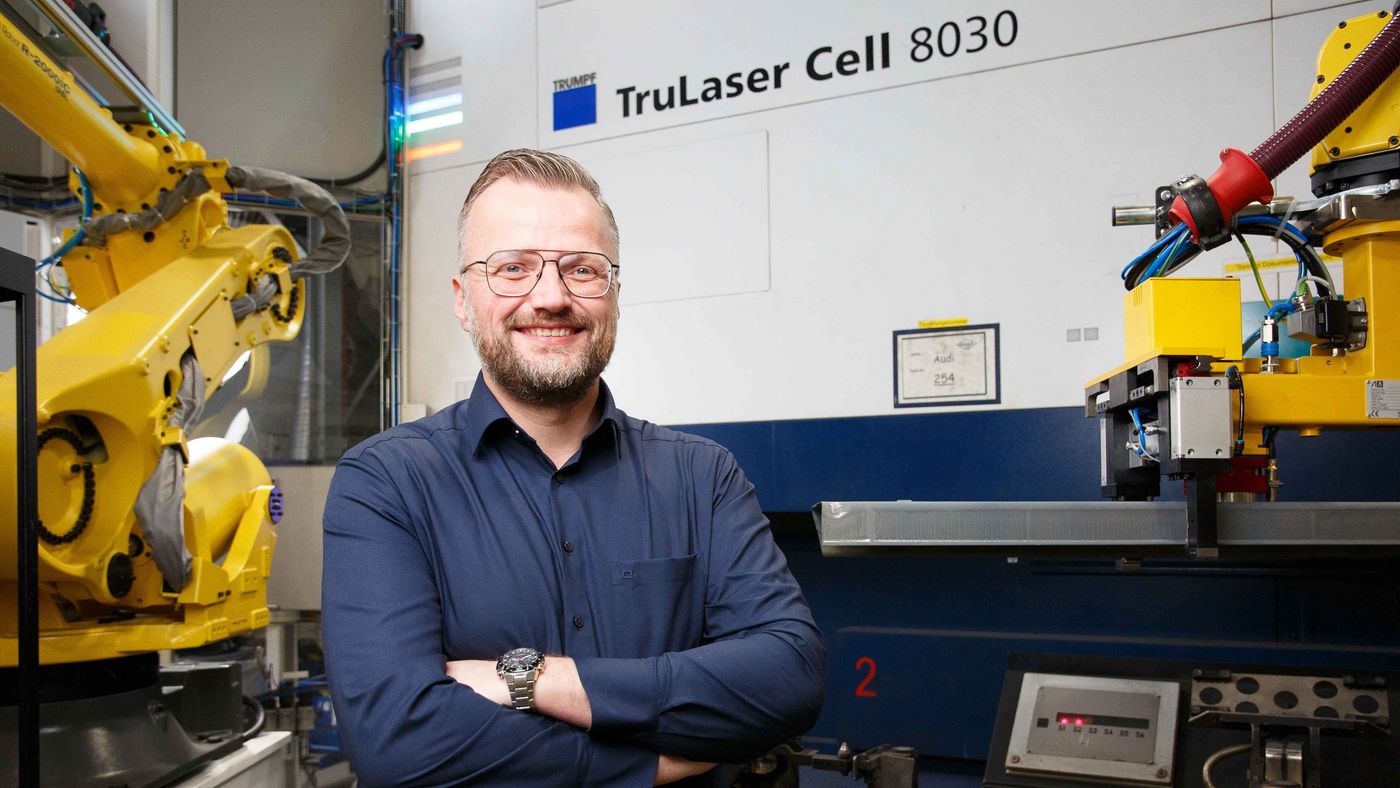

The vehicle supplier GEDIA produces automobile body parts of various sizes. This bandwidth requires a high level of flexibility in production. Economically viable automation is often difficult. When GEDIA received an order for the manufacture of a large quantity of longitudinal bars, it gave the green light for automation. "After the initial planning it was clear that we could utilize two lasers to 100 percent with this one item. The containers needed for automation were supplied from a customer. Perfect conditions", said Pascal Kaufmann, Head of Production at GEDIA. As well as the quantity, the weight and dimensions of the longitudinal bar are also better suited to automated processing: Around 8 kilograms for a length of around 1.80 meters is difficult for employees to handle.

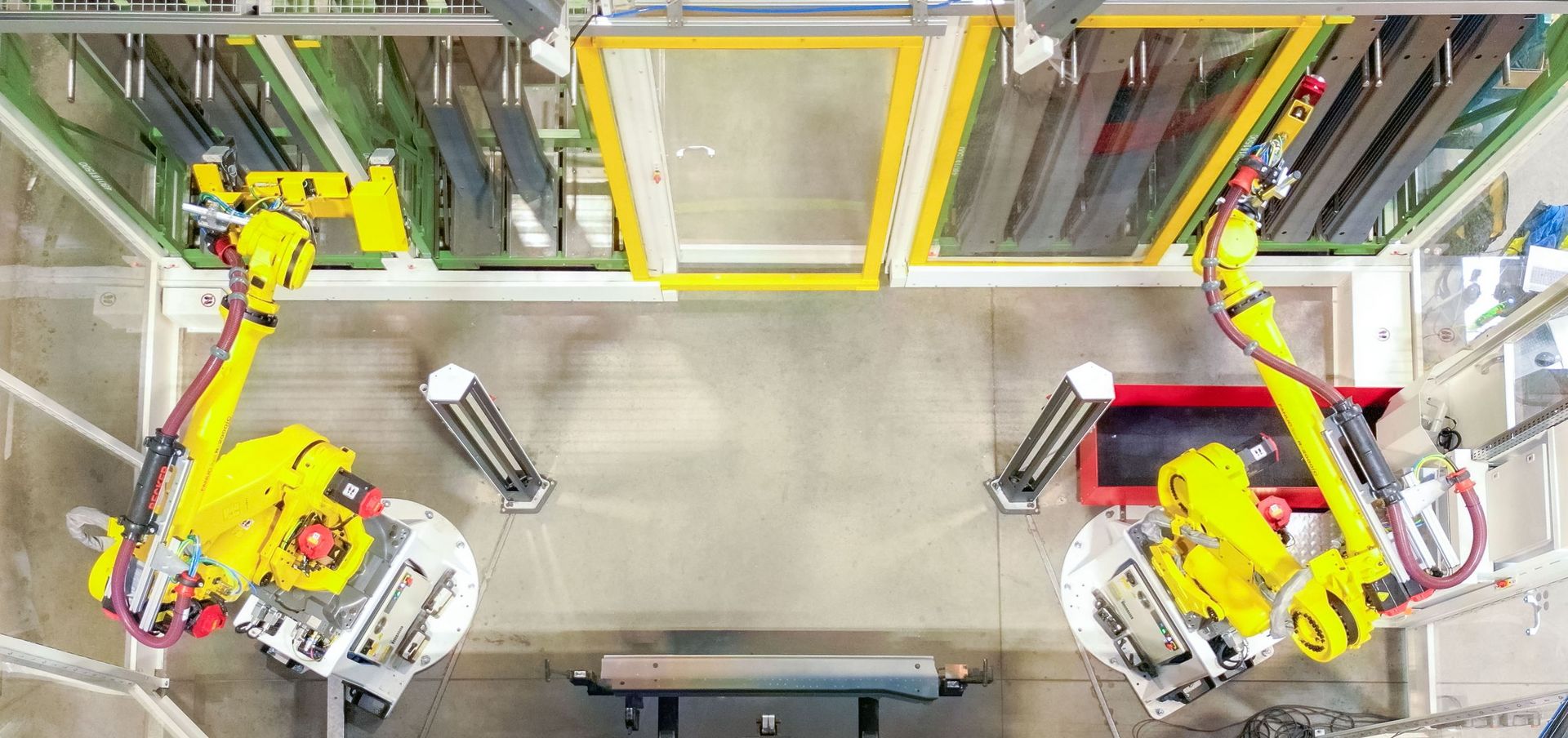

Kaufmann and his colleague Björn Müller, Project Manager for Capital Goods in Machine and Building Management, got in contact with TRUMPF. In a shared workshop with TRUMPF experts and specialists from the solution partner Autom8, they put what they wanted from a fully automated process on the table. "An important point for us was container management", said Müller. He continued: "We require special containers in an automated process. Procurement is expensive, and the handling and storage are also not cost effective." Quality Assurance with suitable camera systems and a sophisticated gripper technology were also on the agenda. "Parts produced from hot forming usually have a funnel shape and a rough surface. They are stacked for further processing on the laser. The automated gripping and, most importantly, the separation of the parts is no small feat", said Müller. Last but not least, there was only limited space available for automation.

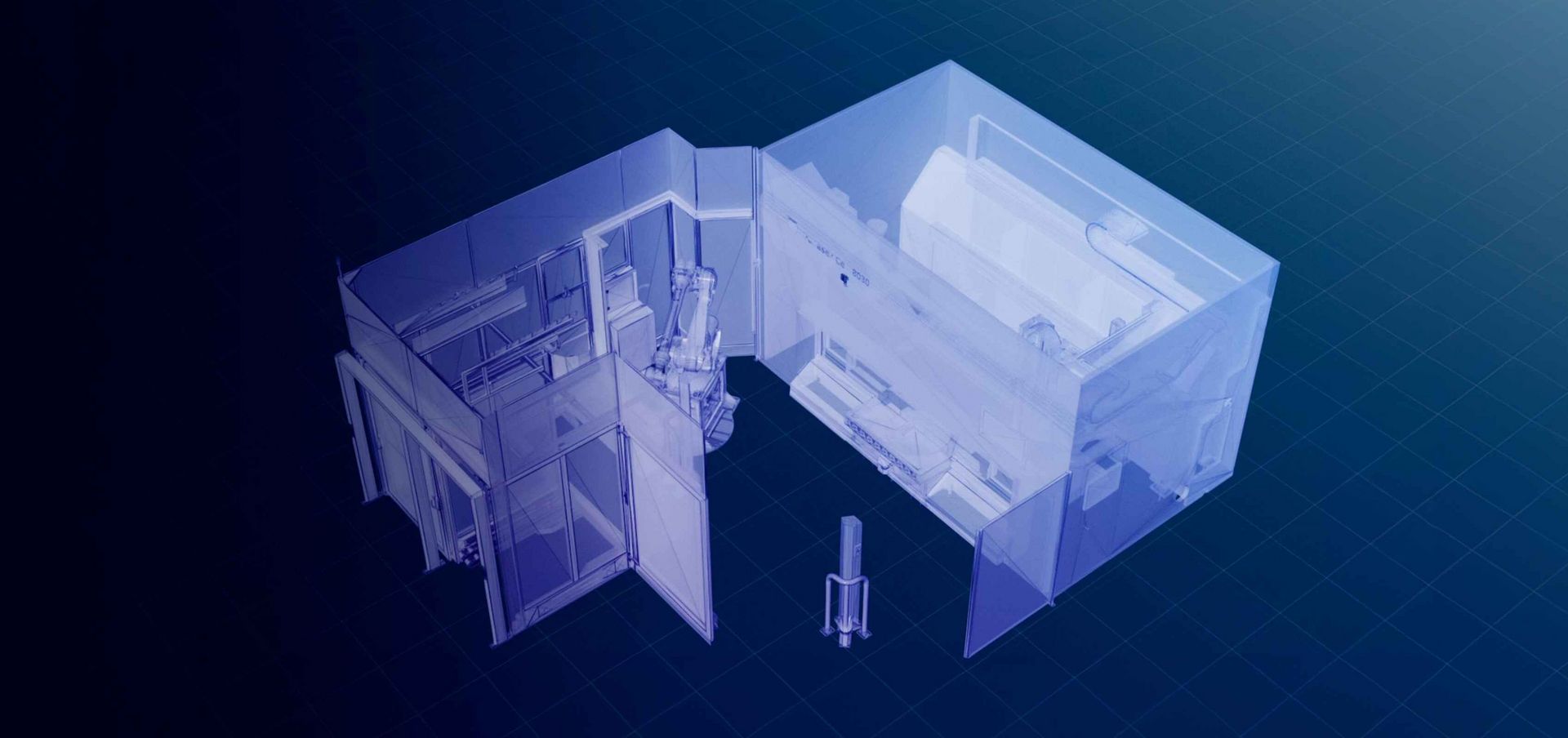

TRUMPF and Autom8 deliver a convincing concept: two of the available TruLaser Cell 8030 machines are equipped with a smart 1-robot automation, which, thanks to its space-saving design, enables both automated and manual operation of the TruLaserCell 8030, and is therefore perfectly suited to the space available at GEDIA production. However shortly after, flexibility was once again requested: Changes in quantity required the automation of another TruLaser Cell 8030 (L60). However, as this system can only be utilized to half of its potential with the production of the longitudinal bar, good advice is expensive. As a result of positive experiences with the first two automations, Kaufmann and Müller then made the next step: They requested a full automation, which would enable the longitudinal bar and another item with similar dimensions to produce 24/7 without a large setup effort and operator intervention.