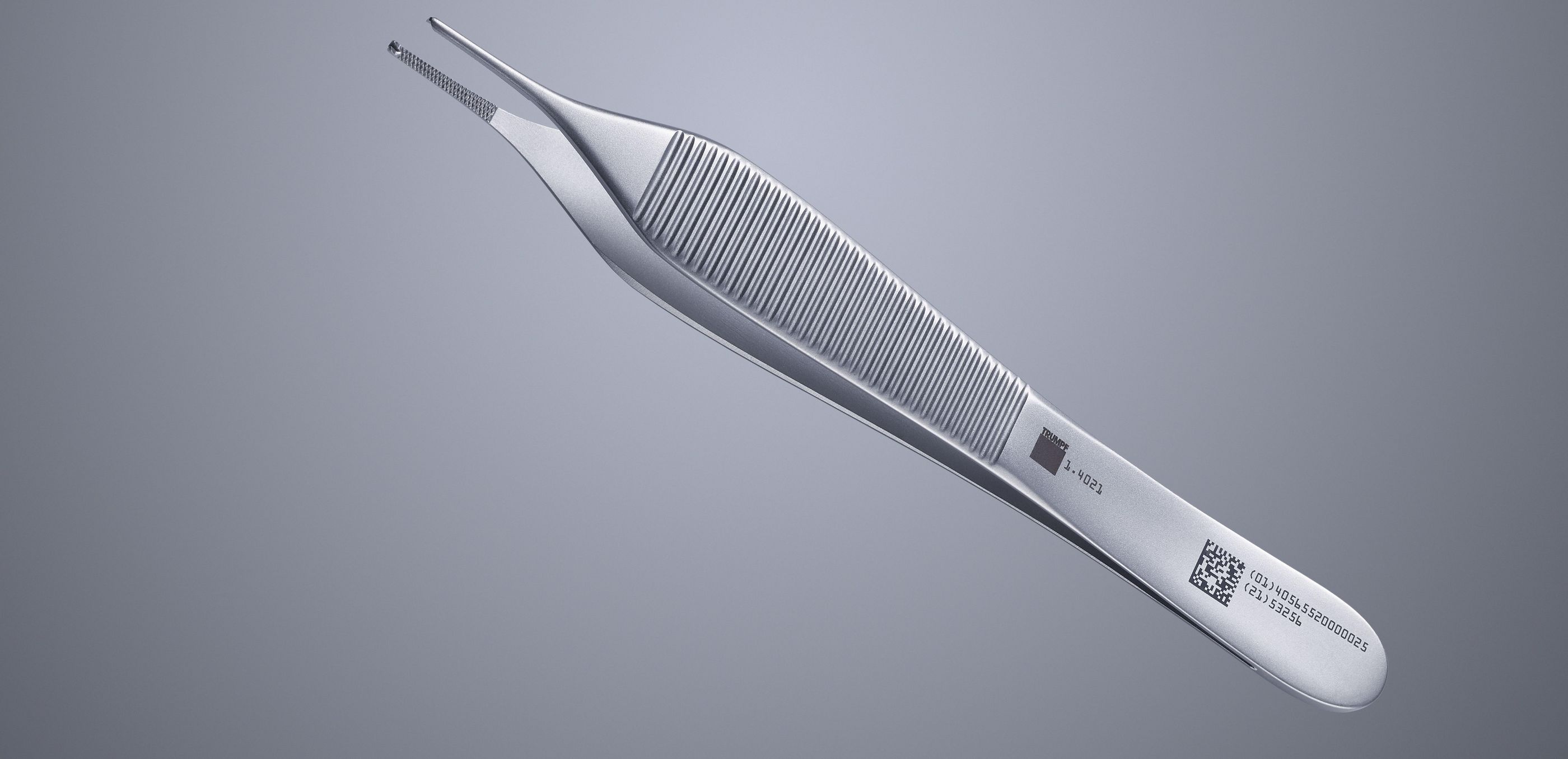

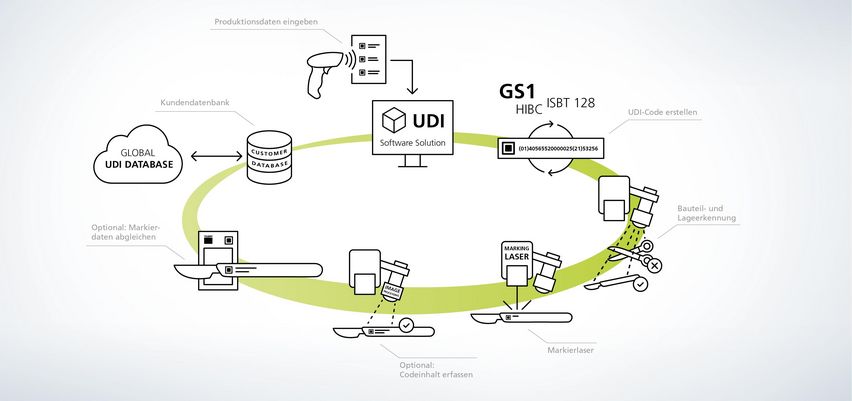

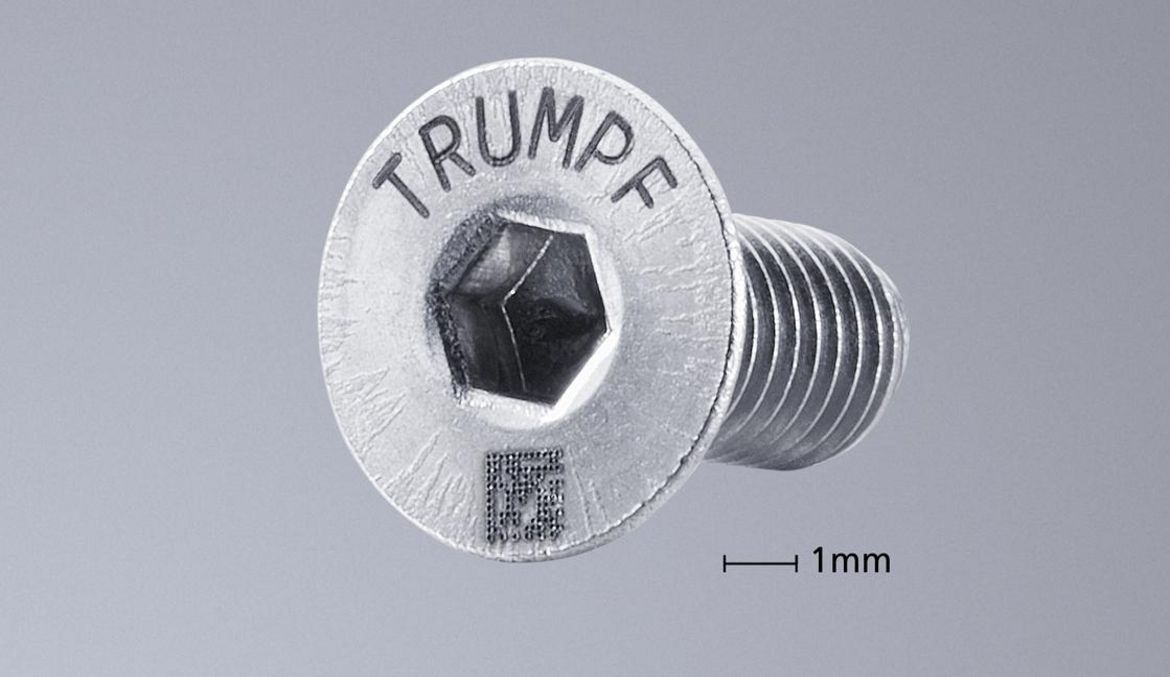

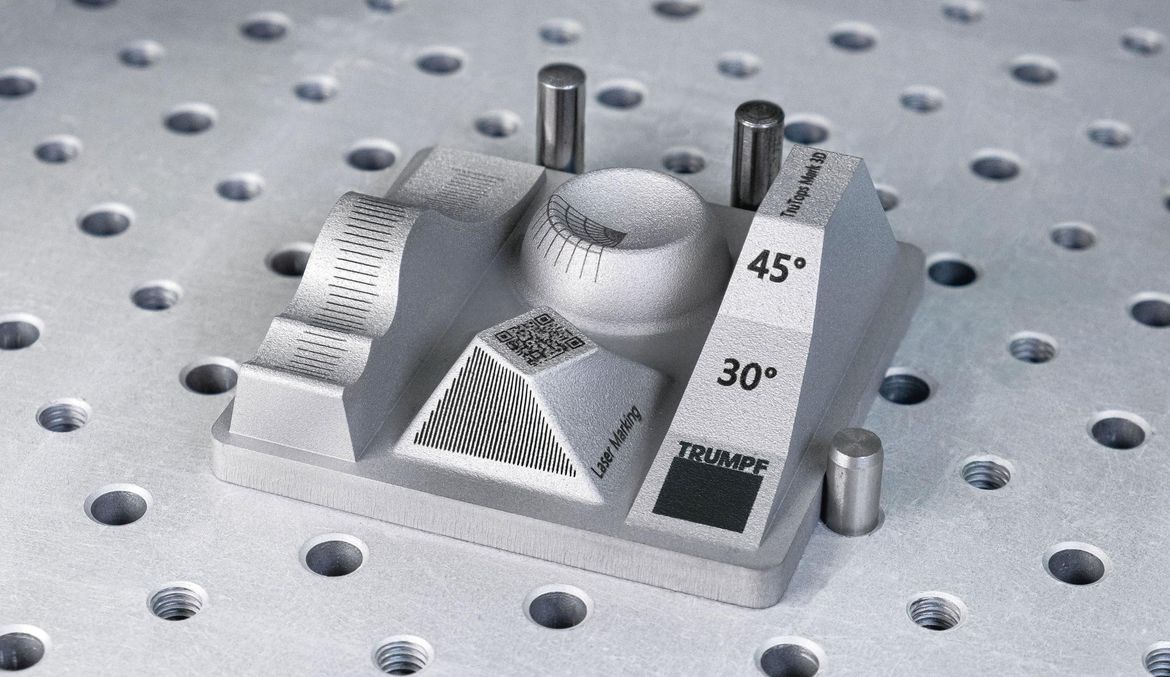

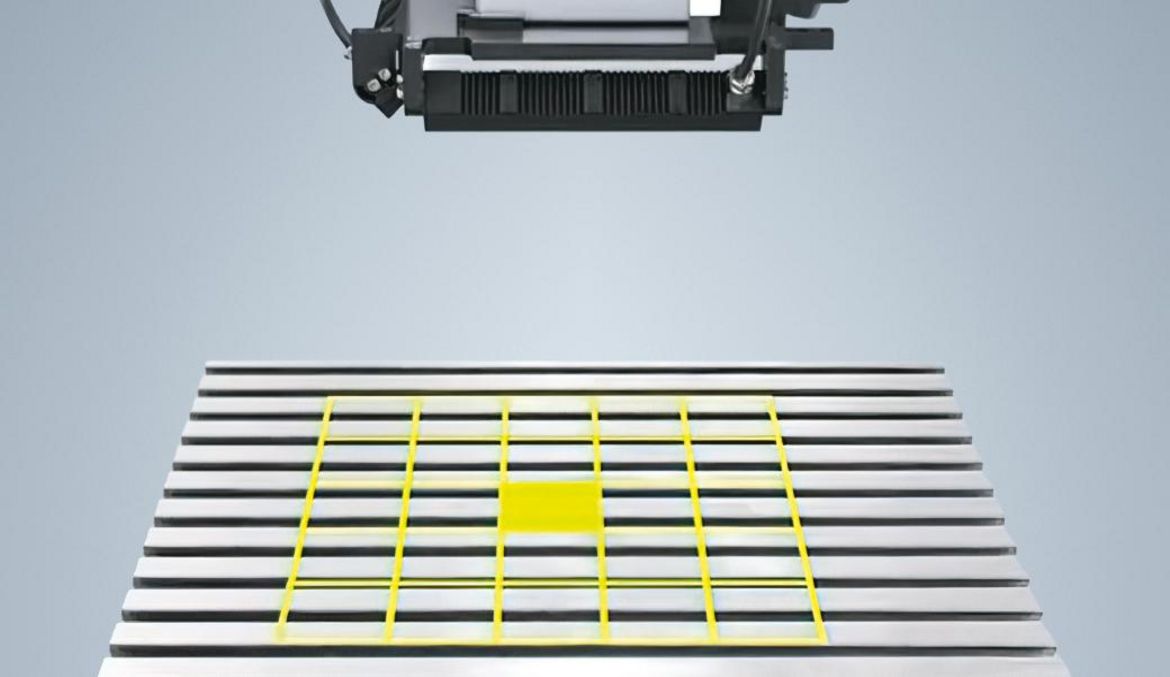

TRUMPF's complete solution for the medical marking laser market offers a comprehensive function standard, which covers the entire process from UDI marking to image processing, data base connection and data capture using external devices such as manual scanners. The modular nature of software modules offers additional simplifications which can be tailored to special customer requests.

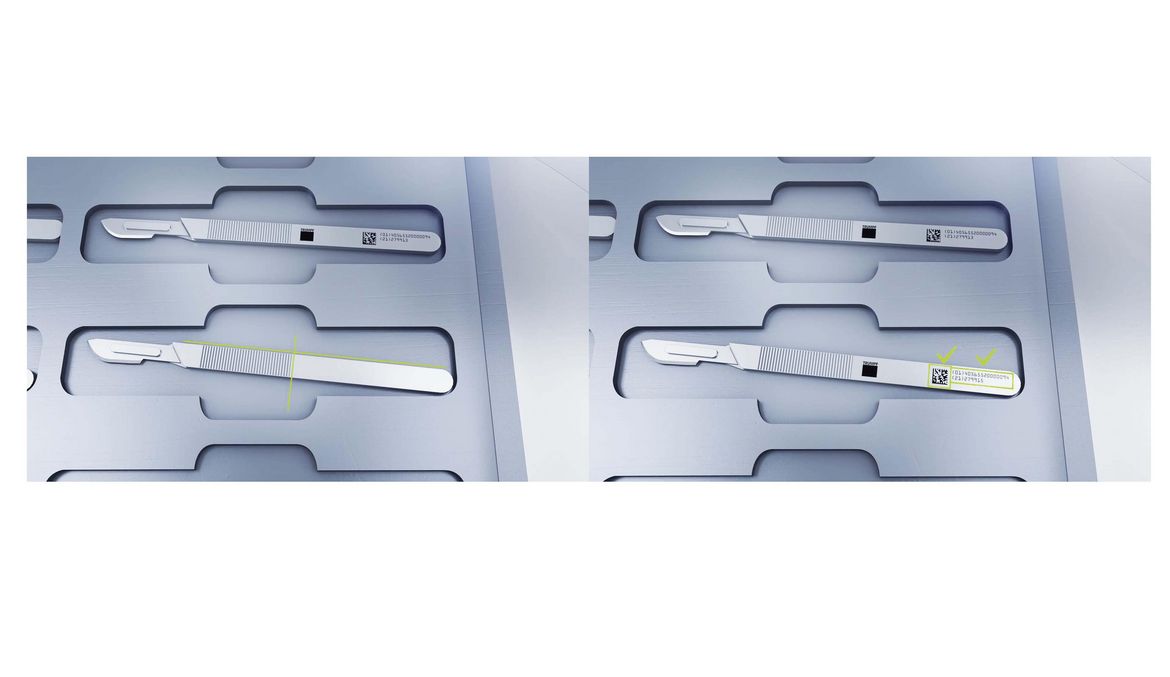

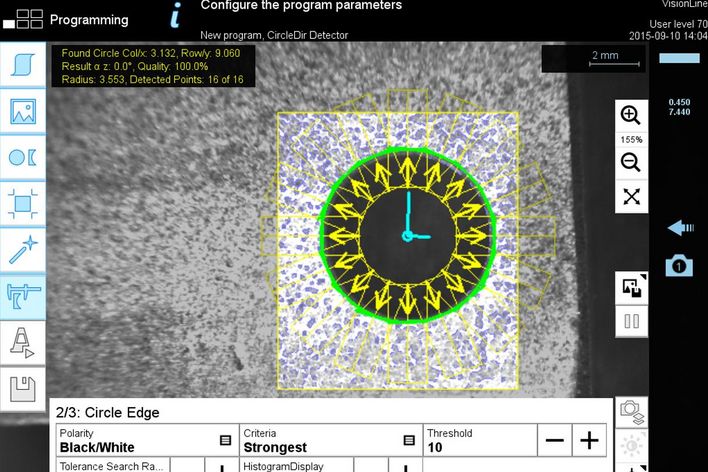

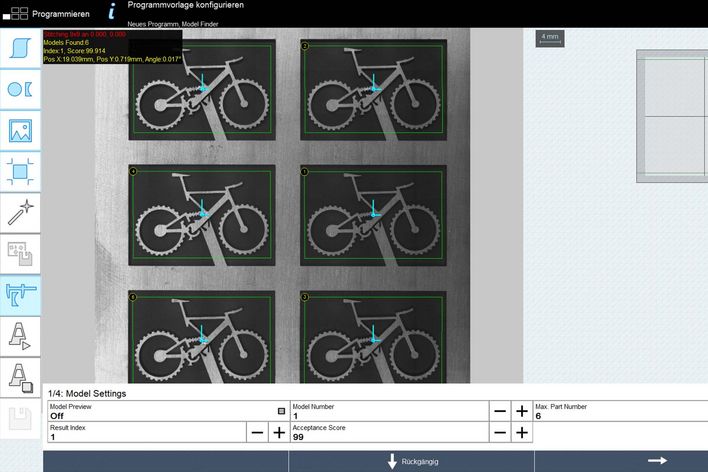

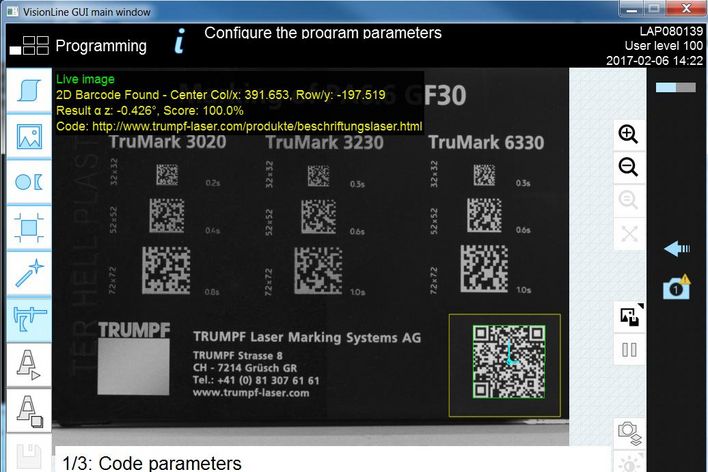

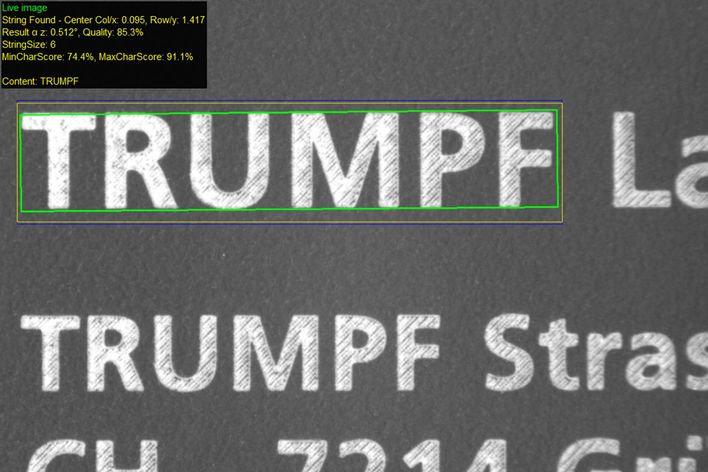

VisionLine image processing provides support throughout the entire UDI marking process with the options Detect, Model, Code and OCR.