Time is money in the construction industry. From receipt of the order to delivery of the products to the construction site usually only takes a few days - daily business for Thomas Goswin: "In addition to quality and price, short delivery times are the focus of our customers. One or two days can make a difference." Goswin knows what he is talking about. The SCHRAG Group, headquartered in Hilchenbach, North Rhine-Westphalia, develops and produces components for industrial hall construction. With four production sites in Germany and subsidiaries in the Czech Republic and Poland, SCHRAG has been one of the market leaders for years. To ensure that this remains the case, Goswin regularly scrutinizes the orientation of his group of companies and its individual business segments. He sees potential for optimization in the largest business unit, Edge Profiles: "More efficient processes can give us the decisive advantage, and we achieve this through automation."

A good plan is needed

However, automated production of edge profiles is no easy feat. "We usually manufacture order-related, predominantly customized parts," explains Goswin, continuing, "But with a team of employees, we have managed to identify parts that have a certain repetitiveness." These are purlins and rafters for the substructure in hall construction. "Our idea was to take these parts off the existing production sites and manufacture them in a completely new automated plant," Goswin says: "To do this, we wanted to put the most modern production plant for lightweight profiles in Europe on a greenfield site." It was quickly found, but, says Goswin, "We are not automation specialists. We therefore sought support for the establishment of a new production site and the associated restructuring of the locations."

Business among equals

From his contact at TRUMPF, Thomas Goswin heard about the Smart Factory Consulting Team which advises and accompanies sheet metal workers on their way to the Smart Factory, independent of machines and manufacturers. The scope of consulting also includes factory planning. Goswin: "I was convinced that the TRUMPF consultants come from the world of sheet metal. I don't have to explain to them what a folded or bent part is. We speak one language."

The kick-off of the project took place in Hilchenbach in February 2020. The SCHRAG project team consisted of all the Site Managers, the Technical Manager, the IT Manager, and other colleagues from the Production, Sales, and IT departments. "My aim was to get as many colleagues as possible on board with their specific expertise. Everyone should feel involved right from the start," says Thomas Goswin, explaining his selection. Smart Factory consultants Robert Herold and Dominique Hensel began the process with detailed ACTUAL analyses at the sites, always in close cooperation with the SCHRAG team. They use analysis tools to examine material, information and production flows. Based on the results, they develop solutions together with the SCHRAG project group to increase efficiency at the sites.

Expansion instead of new construction

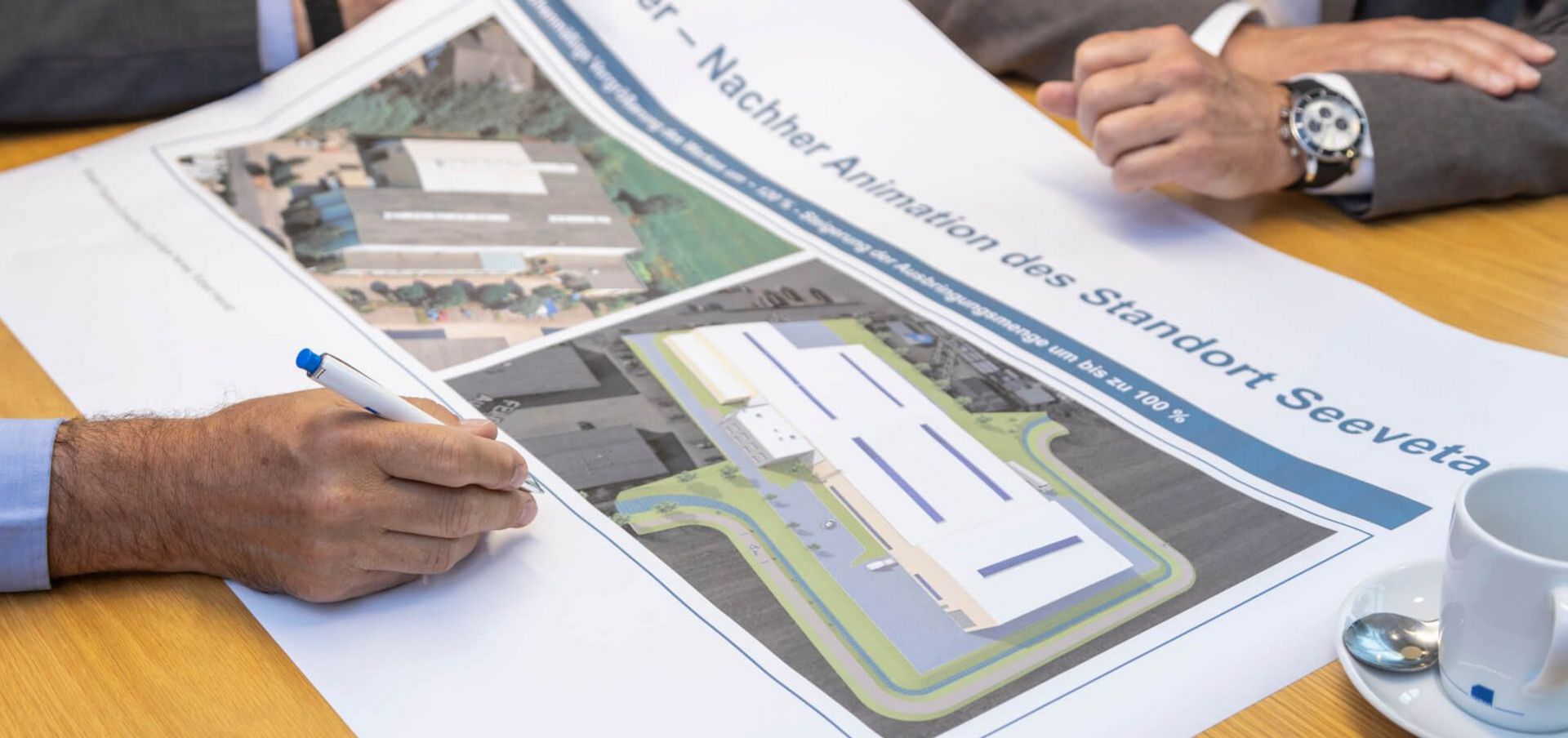

They were also thinking about the construction of the new site. However, the more production figures were on the table, the more attractive an alternative appeared to the project team: Why not expand the existing Seevetal site and make it fit for automated production instead of investing in a completely new site? Robert Herold explains, "The Seevetal site in Hamburg was already specialized in the production of purlins and rafters - and there was a vacant lot there." Dominique Hensel adds, "It became clear that expanding the Seevetal site and optimizing the existing sites would deliver greater added value for the SCHRAG Group than a new building." The plan convinced everyone involved in the project and Thomas Goswin also went along with it: "I went into the planning with an open mind right from the start. The arguments put forward by the consultants, underpinned by profitability calculations and the jointly developed fact base, convinced us all."

Powerful combination: process and technology knowledge

The dream of the most modern production plant for lightweight profiles in Europe is therefore not off the table - only the location will be different. To realize this goal, the Smart Factory Consultants and the project team are getting down to the detailed factory planning for Seevetal. First, the prerequisites for automated production of standard parts must be created there. To this end, the TRUMPF consultants recommend investing in a highly automated roll forming system. But that's not all: Since special profiles are often part of the scope of delivery for a large order and splitting orders is not advisable, a press line including a 12.5-meter press from TRUMPF for special profiles will also be installed in Seevetal. A new coil warehouse serves both production lines. For efficient delivery and removal of materials and parts, a truck plant bypass is part of the plan. A new office building completes the expansion of the site, which is scheduled to start production in 2022.

Dominique Hensel is very satisfied: "This project had a whole new dimension for us. It showed that our combined process and technology knowledge can produce good results even when the classic TRUMPF portfolio isn’t suitable." And Thomas Goswin is also enthusiastic: "I have to admit that I initially had my doubts about the promise that TRUMPF's consulting would be neutral, i.e. independent of manufacturers and machines. But it was worth it to give the Smart Factory consultants the benefit of the doubt. In a great team effort, we worked together to come up with the best solution for the company." With the combination of automated and classic production in one plant, SCHRAG now has a unique selling point compared to the competition, and that spurs Goswin and his team to continue on the path they have chosen. "Relieving the pressure on our individual sites now gives us room for new automation and digitalization solutions. And the further optimization of cross-plant processes and the associated networking of SCHRAG's sites is still on the agenda," explains Goswin, knowing that he can rely on TRUMPF's Smart Factory consultants for this as well.