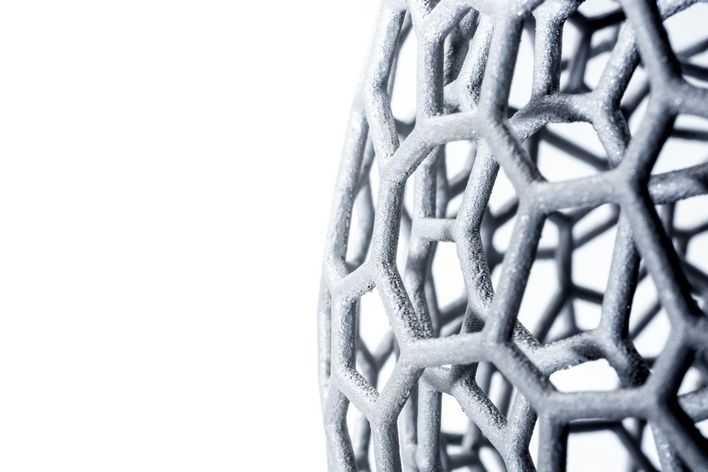

1. Weight of satellite mounting structure reduced by 55 percent

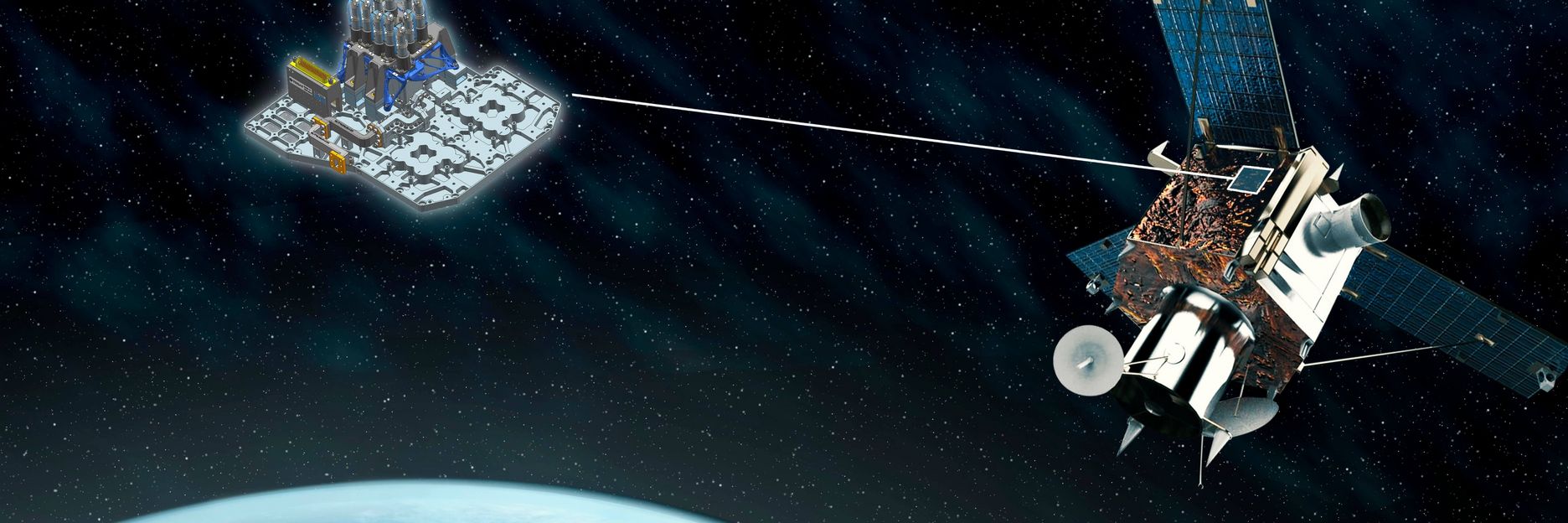

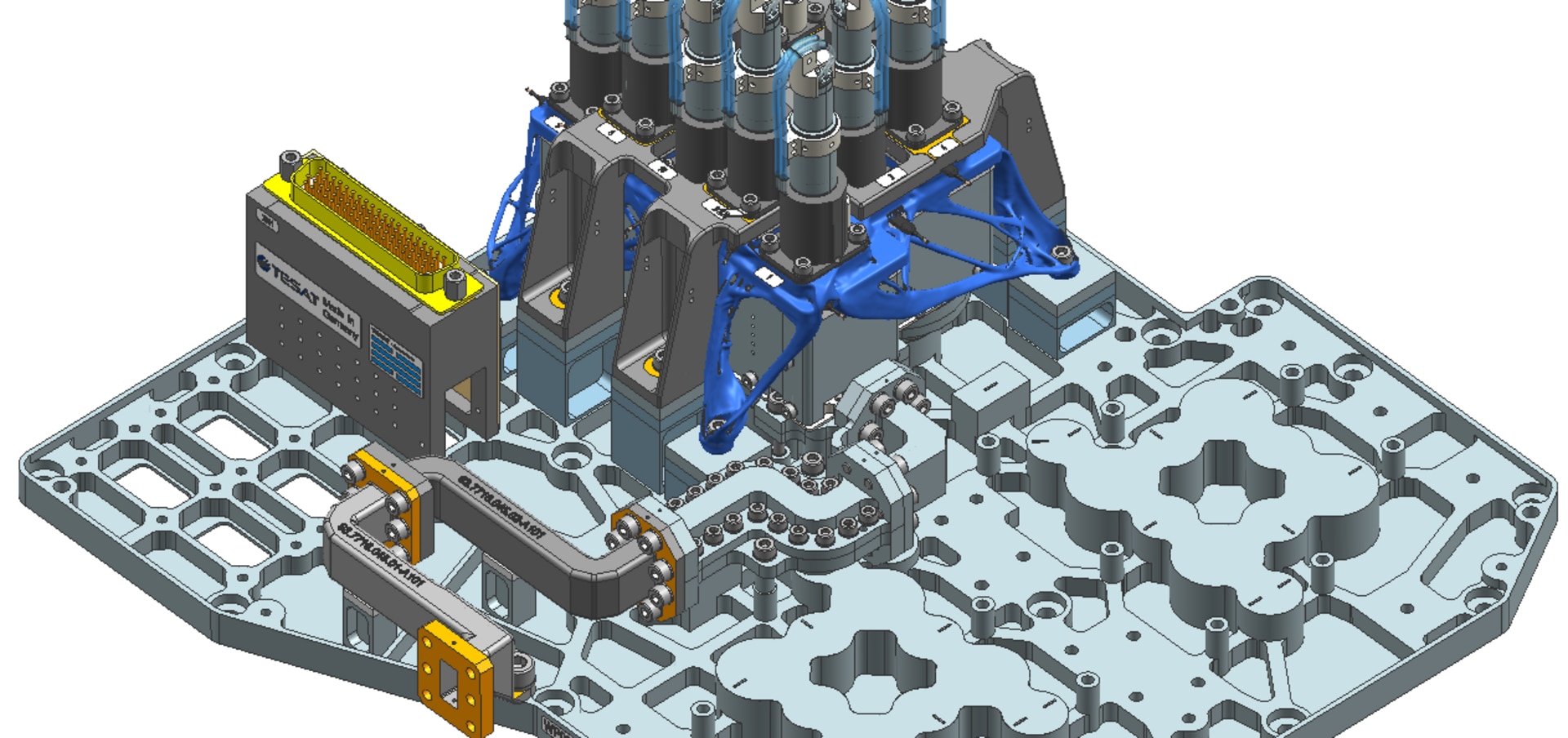

TRUMPF is taking the opportunity of the Paris Air Show to showcase real-life applications of additive manufacturing in the aerospace industry. The high-tech company has been commissioned by the space company Tesat-Spaceroom GmbH& Co.KG to produce a 3D-printed mounting structure for Germany’s Heinrich Hertz communications satellite, which will be used to test the space-worthiness of new communication technologies. The mounting structure includes strap-on motors that are used to modulate microwave filters. In collaboration with the company AMendate, engineers succeeded in optimizing the topology of the mounting structure and reducing its weight by 55 percent. The mount now weighs just 75 grams instead of 164 grams. The team of experts printed the redesigned part on TRUMPF’s TruPrint 3000 3D printer. The new geometry cannot be produced using conventional methods. As well as being lighter, the optimized mounting structure is also more robust. During the launch of the satellite the new mounting structure will withstand the same high forces and will hold its shape better. The Heinrich Hertz satellite mission is carried out by DLR Space Administration on behalf of the Federal Ministry of Economics and Energy and with the participation of the Federal Ministry of Defense.

2. Cost of engine parts reduced by three quarters

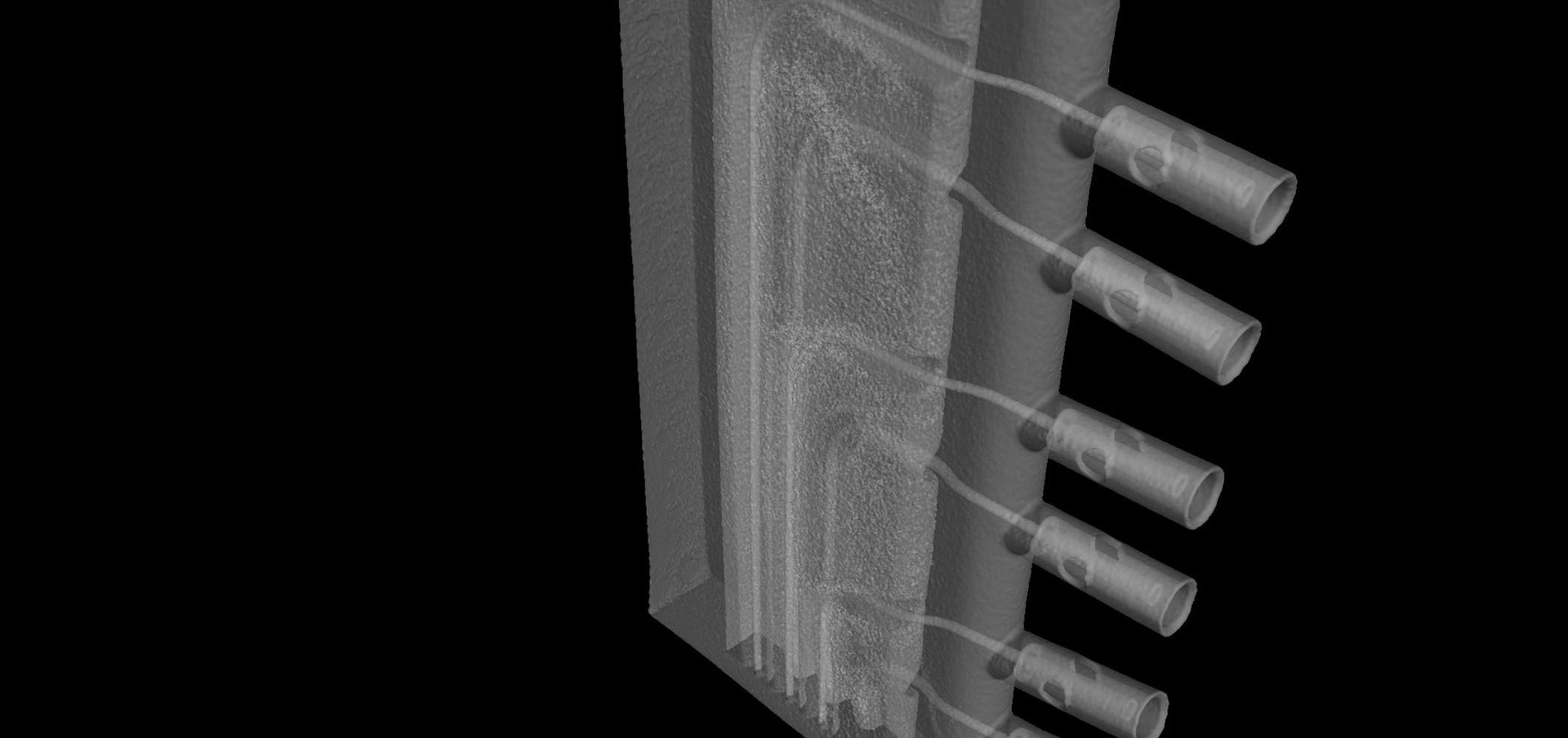

TRUMPF is also showcasing an AM use case for the aviation sector at the Paris Air Show. In collaboration with Spanish supplier Ramem, the TRUMPF experts have employed 3D printing to optimize a part known as a “rake.” Manufacturers use this part during engine development to measure the pressure and temperature of the engine. These kinds of measurements are an important part of testing aircraft performance. Mounted directly in the engine’s air flow, rakes are exposed to extreme temperatures and high pressure. To deliver accurate measurements, they must conform to precise dimensional requirements. Producing rakes by conventional means is an expensive and time-consuming process. Workers produce the base structure on a milling machine before inserting six delicate tubes, welding them into place and sealing the body of the rake with a cover plate. If just one of these tubes is out of place, the rake has to be scrapped. TRUMPF produced an optimized rake geometry on the TruPrint 1000 3D printer. Redesigning the part in this way makes it quicker for the manufacturer to produce and reduces the amount of material used by around 80 percent, ultimately slashing the overall cost by 74 percent.

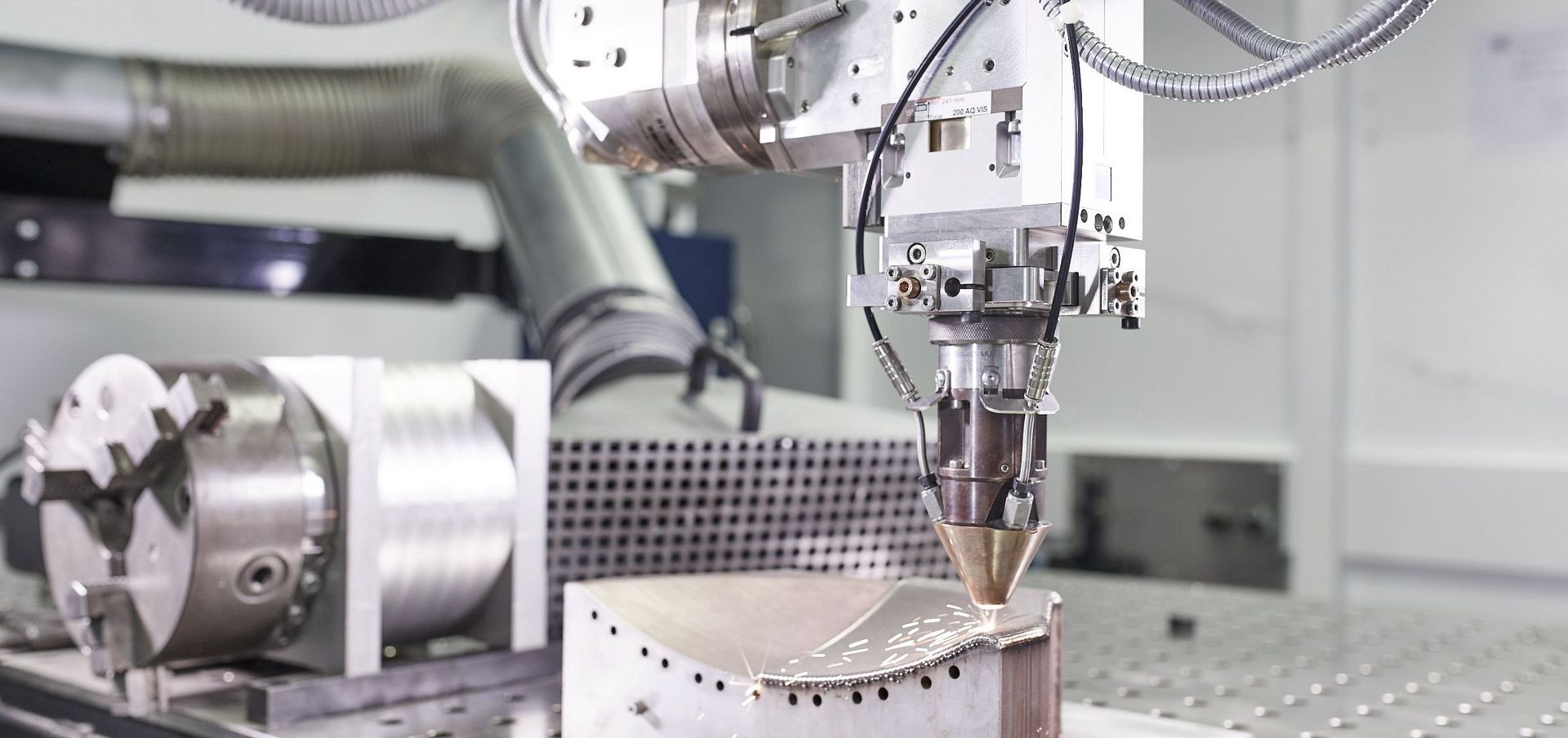

3. Making engine blades easier to repair

High-pressure compressor blade – also known as a 3D aeroblade – are used in aircraft engines and must withstand extreme changes in temperature during flight. They are also in constant contact with dust and water, and they typically show signs of wear on the edges and tips. Aviation engineers have to periodically repair the blades to maintain engine efficiency. The additive technology Laser Metal Deposition (LMD) is perfect for this job. In some sections of the blades, the material is just 0.2 millimeters thick. Conventional methods quickly reach their limits in these kinds of applications. With LMD technology, however, the laser can be positioned with an accuracy of approximately one hundredth of a millimeter before it applies a precisely calculated dose of energy. At the same time, the system feeds in material of exactly the same composition as the part itself. Depending on the application, this process typically takes just a few minutes. It makes it easy to repair the blades multiple times, significantly reducing the cost per part in each engine overhaul.