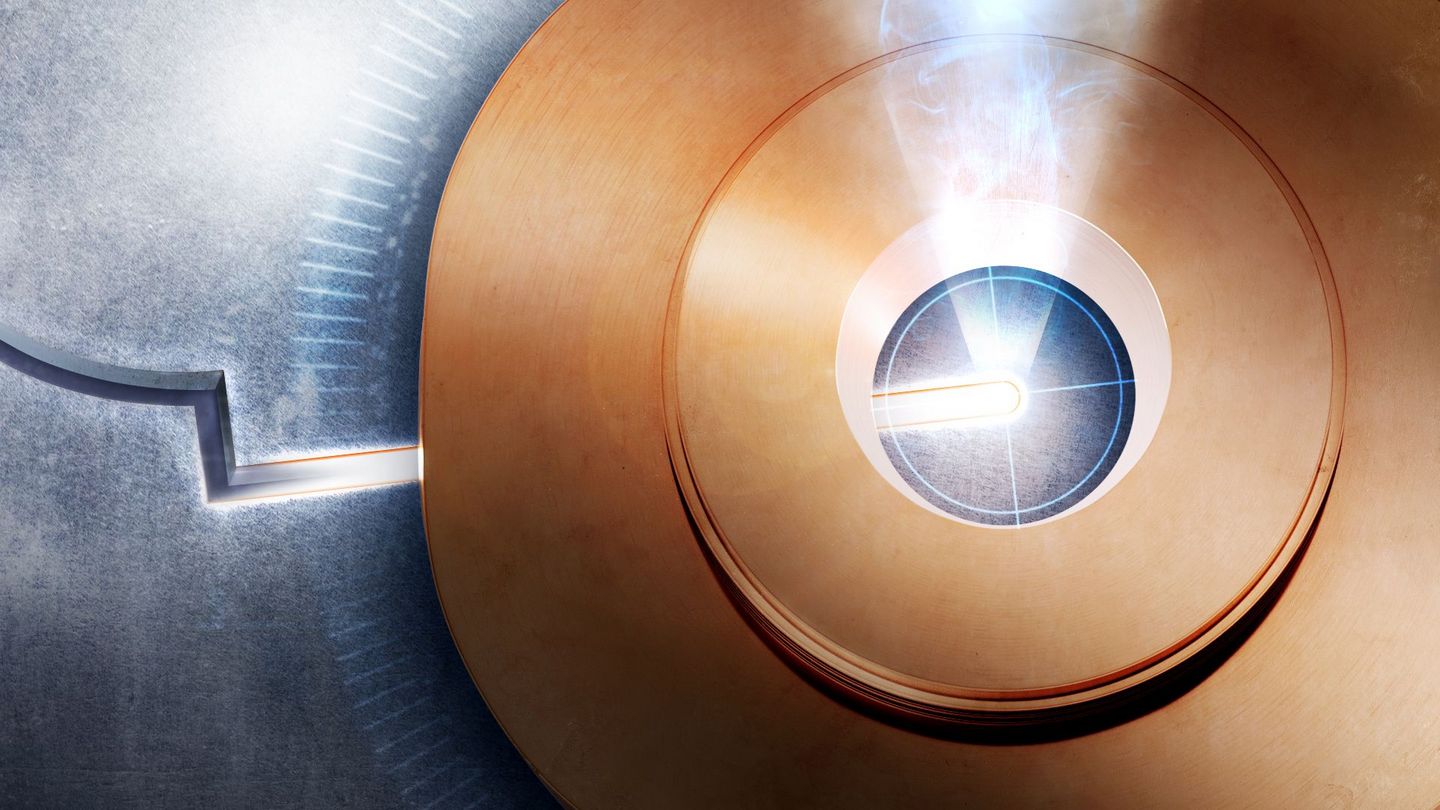

The cutting process is overseen from above in real time, with monitoring through the copper nozzle. The sensor system observes the kerf, determines the optimal feed, and readjusts if need be – hundreds of times per second. This minimizes cutting interruptions caused by material differences such as fluctuations in sheet thickness, rust, or coating contaminations. In the event of a potential cutting flaw, Active Speed Control stops the machine, and the TruTops Monitor software immediately informs the operator that intervention is necessary. Active Speed Control also reduces the formation of burrs and dross. The minimized reject rate leads to lowered parts costs.

Large strides forward: intelligent sensor systems increase productivity

One part of our vision is already a reality. Intelligent assistance systems for laser cutting develop execution strategies, for example, which prevent collision with tilting parts, or make post-producing of parts out of scrap skeletons easier. Even nozzles are automatically inspected and replaced if necessary. The proportion of machine functions which control processes independently is ever-increasing.

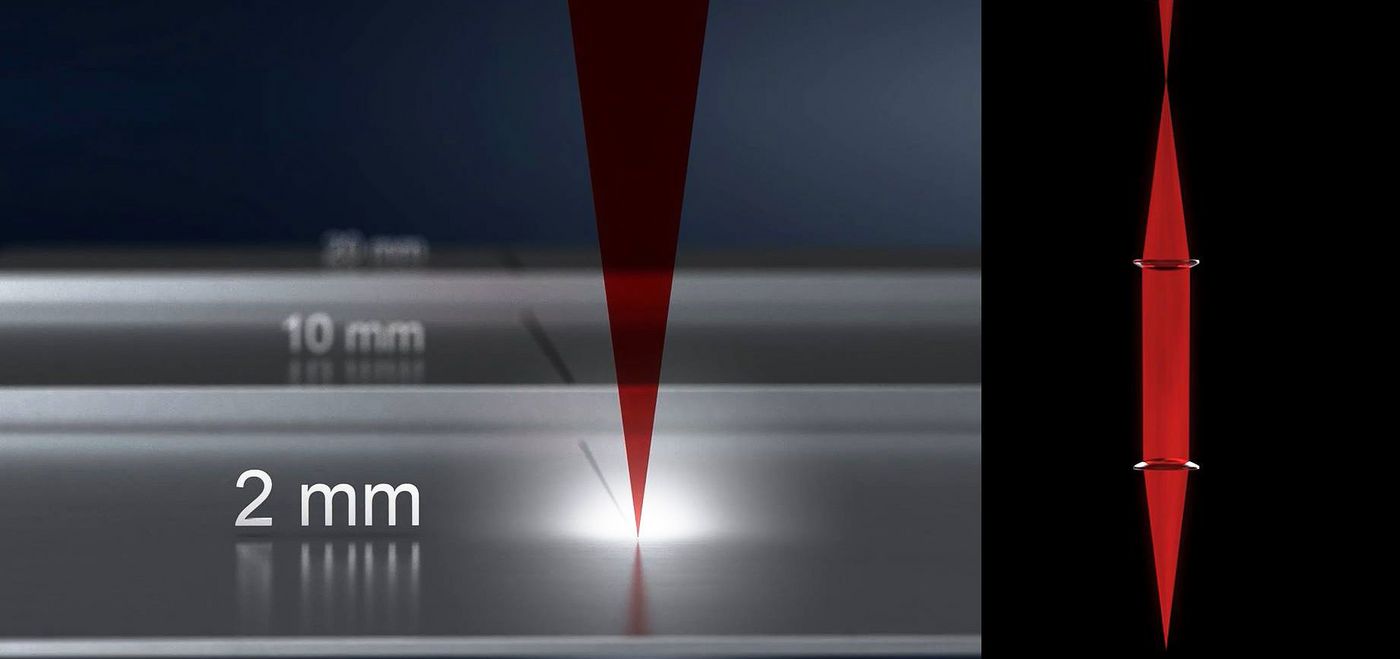

An important milestone on the path to autonomous machines is the newly developed Active Speed Control system for adaptive feed control. The system monitors the kerf through the nozzle, oversees the cutting process, and independently regulates feed speed. It ensures the right feed level for flame and fusion cutting, even in the event of thickness variations in a sheet, or if the sheet has been affected by quality fluctuations (i.e. rust or coating remnants). Data analysis makes quick and stable cutting possible. This can prevent disruptions to cutting, and noticeably reduces the number of reject parts. The operator is also relieved. They can pull up the most important process parameters or a live-image through the nozzle any time, and will be actively informed if the need for intervention arises. Tapeshots which were necessary up to this point are now a thing of the past.

Active Speed Control oversees the process, controls cutting

Comparison between laser cutting with and without feed control

Take a look behind the scenes

TRUMPF is a pioneer in the laser cutting industry. To ensure we remain so in the future, we research tirelessly, always on the boundary of technological possibilities. We have a clear vision on the path to autonomous machines: to make the work of operators easier, through simple and sophisticated operating concepts. Our solutions give them the ability to respond to potential malfunctions with ease. The focus is on cost-effectiveness, as compared to non-assisted processing, the part costs for autonomous processes are significantly lower.

Ready for the future – be prepared for anything with intelligent functions from TRUMPF

Assistance systems make life easier; they shorten and simplify many processes in laser cutting, as well as make them noticeably more reliable. This allows you to put your machines to optimal use, and minimize manual interventions. In addition to the newly developed Active Speed Control, TRUMPF also offers solutions for every process step in the form of intelligent functions. A compact selection of functions for autonomous laser cutting can be found here.

Leading the way – TruLaser Center 7030

Curious about the future of laser processing?

What does autonomous laser cutting mean for your parts production? What benefits are there to you? Our 2D laser cutting experts would be happy to answer these as well as other questions.