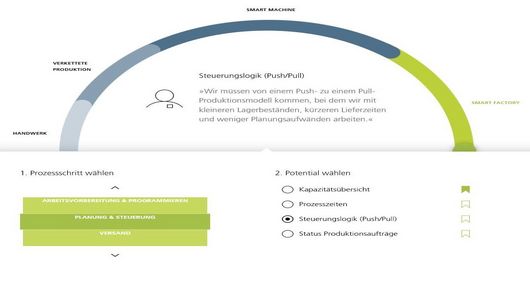

Die Smart Factory richtet sich an alle Blechbearbeiter – vom kleinen und mittleren Lohnfertiger, der in die digitale Vernetzung einsteigt, bis zum Kunden mit vollautomatisierter Fertigung.

TRUMPF Smart Factory Chicago

Komplett vernetzt geht bislang nur in der Theorie? Wir treten den Gegenbeweis an und demonstrieren in Chicago, wie eine komplett vernetzte Produktion in der Praxis funktioniert. Im neuen Technologiezentrum von TRUMPF spielen Menschen, Maschinen, Automatisierung und Software bereits heute perfekt zusammen. In der Smart Factory erleben Blechbearbeiter vernetzte Fertigungslösungen in einem realistischen Umfeld.

Ihr Gewinn durch digitale und physische Vernetzung

Durch Vernetzung wird Ihre Fertigung transparent. So wissen Sie immer, was gerade passiert und können besser planen. Indirekte Abläufe werden automatisiert. Sie produzieren schneller und flexibler, Ihre Prozesse werden beherrschbarer. Ein entscheidender Vorteil – besonders bei kleineren Losgrößen.

Betrachten Sie die Smart Factory in Chicago aus der Luft!

Egal wo Sie sich befinden – mit unseren intelligenten Vernetzungslösungen haben Sie Ihre Smart Factoy immer im Griff.

Die Vorgänge in unserer Smart Factory aus unterschiedlichen Blickwinkeln

Sie möchten die Fabrik der Zukunft live erleben?

Hier haben Sie die Möglichkeit sich für einen Besuch anzumelden, um unsere Smart Factory in Chicago hautnah zu erleben. Einfach das Formular ausfüllen und abschicken. Wir freuen uns auf Sie!

Weitere Impressionen