A shared language connects. This also applies to machines in the industrial IoT (Internet of Things). The easier the sharing of information, the more efficient the work. VDW has therefore developed umati (universal machine tool interface) together with TRUMPF and 16 other project partners. A universal interface that securely, seamlessly and effortlessly integrates machine tools and equipment into customer-specific and user-specific IT ecosystems. It is a standard for users in Germany and all over the world, opening up new opportunities for the Industry 4.0 era.

Smart Factory – What is it?

A Smart Factory is a production environment in which people, machines, automation and software work together in perfect harmony. The notion of the ideal Industry 4.0 production landscape presents a major challenge to many sheet metal processing companies. Before a highly efficient, flexible and transparent shop floor that satisfies even the strictest of requirements can be achieved, one thing usually comes first: the clean up. Because "chaos" cannot be digitalized. We help you bring order to your production processes and take the next logical step in the technological evolution: consistent networking of the material flow, information flow, automation and process optimization.

Industry 4.0 refers to the Fourth Industrial Revolution – also known as the "digital transformation". Its aim is optimal positioning of industrial production for the future.

A Smart Factory is a production environment in which people, machines, automation and software work together perfectly.

We offer a modular solution for your Smart Factory. Sheet metal processors can use this concept to equip their production facilities to meet rapidly changing market and customer requirements.

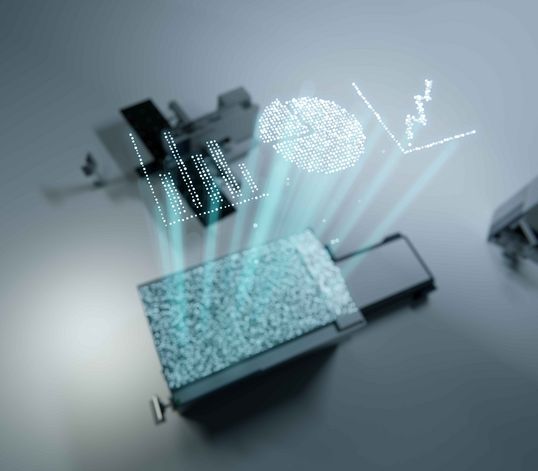

Digital networking is at the heart of Industry 4.0, offering enormous potential to increase flexibility and productivity through manufacturing technology computerization and digital business platform development. It links different components within and beyond a production facility. The factory of the future sustainably optimizes processes and drastically shortens processes.

What specific advantages does a Smart Factory have? Smart networking makes production transparent. Sheet metal processors then always know what is happening and can plan better. Indirect processes are optimized. Digital factory operators have faster and more flexible production and their processes become more manageable. A crucial advantage – especially for smaller lot sizes. The basis of the Smart Factory's communications is IoT (Internet of Things). Everything communicates with everything else in the "IoT". The product communicates the information required for production to the Smart Factory.

Smart Factory customers get tailor-made solutions in three steps according to their specific needs: from a simple start or step-by-step adaptation through to fully networked systems. Regardless of the situation, the goal on the path to a completely networked Smart Factory is clear: to bring greater transparency, flexibility and, most importantly, economy to the entire process.

The potential of Industry 4.0: how do machines in the Smart Factory communicate with each other?