Satisfying the most demanding requirements, even in series

Thanks to slab technology, the ultrashort pulse lasers of the TruMicro Series 6000 generate laser pulses which can be linearly amplified to very high pulse energies. As the parameters can be selected with great flexibility, even demanding processes can be optimally realized. Smoothly implement the high-quality and stable lasers of the TruMicro Series 6000 in your batch production, for example in Consumer Electronics, to cut glass or separate flexible printed circuit boards.

Individually combine demanding parameters such as high pulse energies with ultrashort pulse duration.

The ultrashort pulse lasers generate high average power due to high pulse energies.

Whether IR, green or UV – selecting the correct wavelength means the most varied of materials can be processed in the best possible way.

With the TruMicro Series 6000, you will receive industrial, high-quality series products based on established components.

The internal power control ensures stable output parameters and a homogeneous process result.

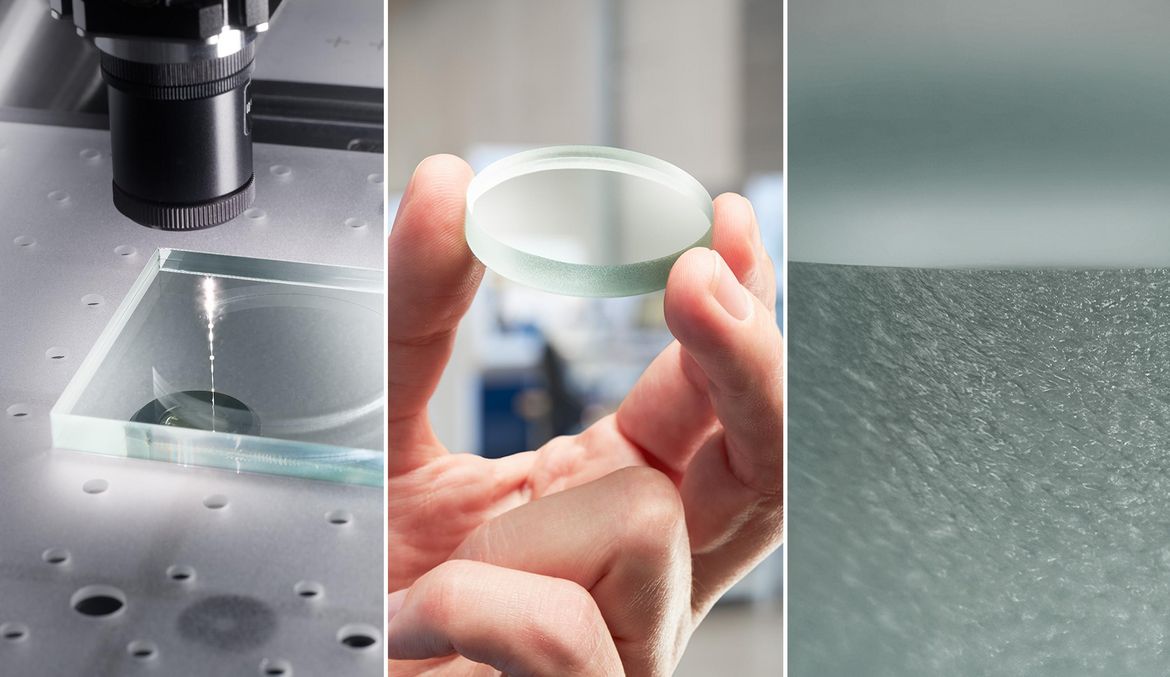

Glass modification

Extreme thicknesses greater than 10 mm can be efficiently processed and then cut with TRUMPF TruMicro lasers and TOP Cleave optics. After cutting, it is not necessary to post-process the cutting edge, such as by grinding or polishing.

Cutting copper foil

The finest structures to the dimension order of micrometers can be cut precisely with a minimal heat-affected zone. This is true even for materials with high reflectivity such as copper alloys.

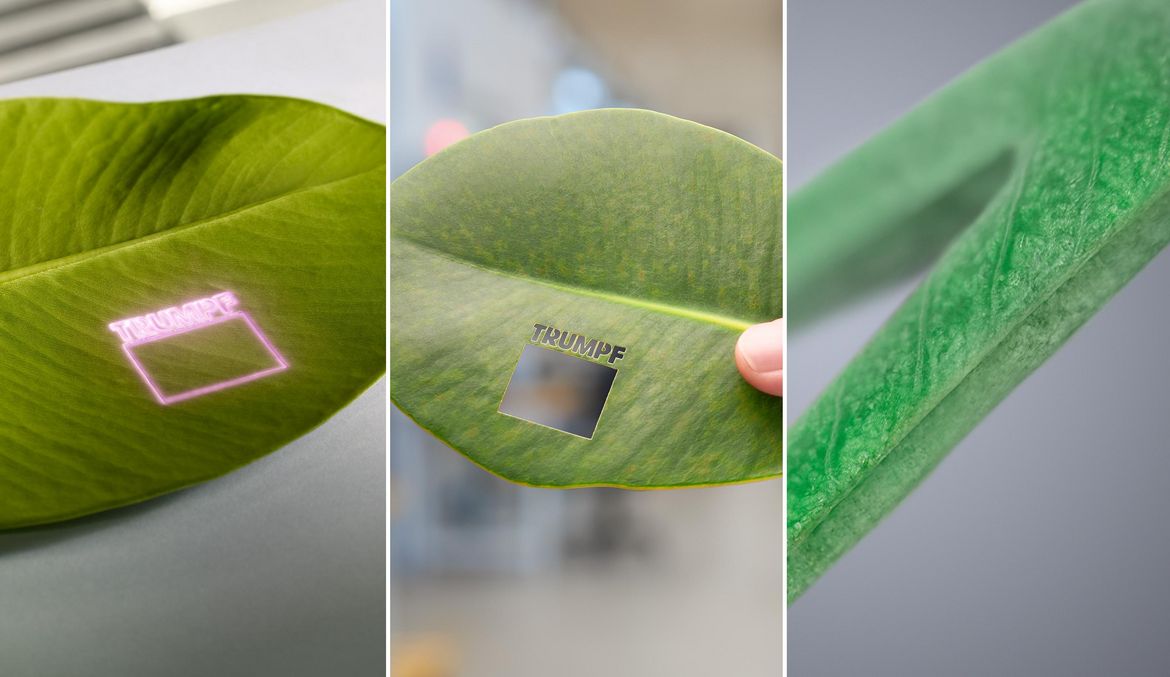

Cutting organic material

The combination of ultrashort durations with high intensity enables microprocessing with incomparable precision. Even highly sensitive organic material can be cut without damaged or burned edges.

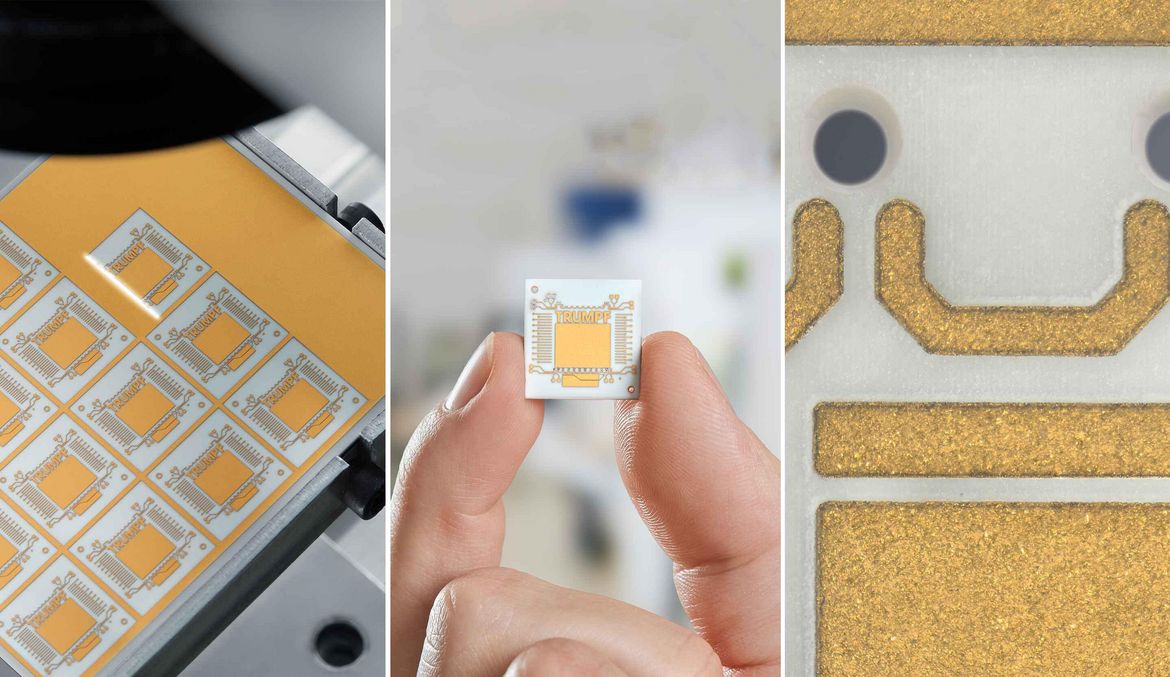

Ablation of gold and ceramic

The TruMicro 6020 cuts and processes technical high-performance ceramics for power electronics and consumer electronics. Precise ablation creates conductive paths, replacing etching processes - an environmentally friendly advancement.

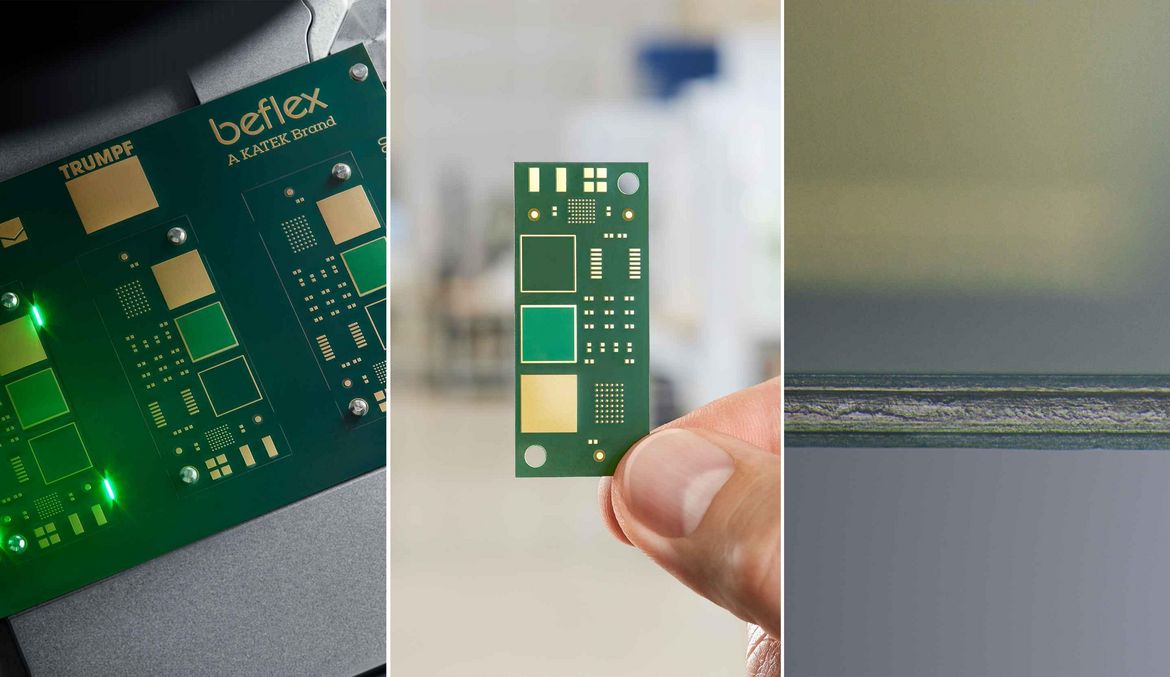

Cutting of printed circuit boards

With the green wavelength, you can process flexible printed circuit boards (FPC) for the electronics industry and medical technology. The laser guarantees quick and precise cutting, without a heat-affected zone. The best edge qualities are achieved, even with plastics.

Wood cutting

The TruMicro 6220 cuts wood with precision. Thanks to advanced ultrashort pulse technology, organic materials are processed without leaving any residue.

|

TruMicro 6020

|

TruMicro 6220

|

TruMicro 6320

|

|

|---|---|---|---|

| Laser parameters | |||

| Average output power | 200 W | 100 W |

30 W (< 500 fs) or

50 W (< 850 fs) |

| Beam quality (M²) | < 1.3 , optional M² < 1.2 | < 1.3 , optional < 1.2 | < 1.3 , optional < 1.2 |

| Wavelength | 1030 nm | 515 nm | 343 nm |

| Pulse duration |

< 850 fs or

< 5 ps |

< 850 fs |

< 500 fs or

< 850 fs |

| Maximum pulse energy |

200 µJ for 1 MHz or

2 mJ with 100 kHz |

100 µJ at 1000 kHz |

37.5 µJ at 800 kHz (30 W)

50 µJ at 1 MHz (50 W) |

| Maximum repetition rate | 50000 kHz QCW mode | 2000 kHz | 2000 kHz |

| Structural design | |||

| Dimensions of laser head (W x H x D) | 600 mm x 366 mm x 735 mm | 600 mm x 366 mm x 735 mm | 600 mm x 366 mm x 735 mm |

| Dimensions of supply unit (W x H x D) | 446 mm x 915 mm x 725 mm | 446 mm x 915 mm x 725 mm | 446 mm x 915 mm x 725 mm |

| Installation | |||

| Ambient temperature | 15 °C - 35 °C | 15 °C - 35 °C | 15 °C - 35 °C |

The technical data of all product versions as a download.

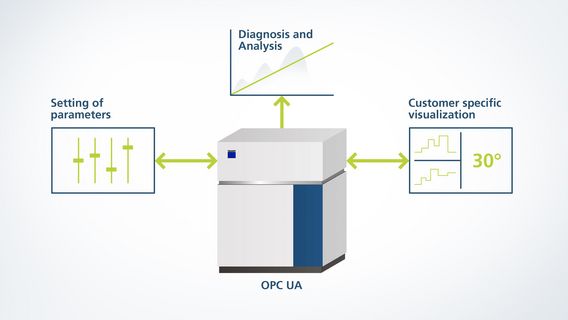

TruControl

TruControl is the quick and easy-to-use control for TRUMPF solid-state lasers. It regulates the laser power in real time in order to deliver reproducible results. TruControl manages, controls, and visualizes the interface configuration. You benefit from a uniform control architecture across all laser technologies. The lasers have interfaces to control intelligent TRUMPF optics, such as monitored CFO focusing optics or PFO scanner optics. You can easily program the processing optics via the laser control system. The remote support service provided by TRUMPF means that you receive off-site support within seconds. This will allow you to avoid service calls or be as prepared as possible and increase the availability of the laser device.

The precise time definition of the individual laser pulses is relevant for an optimum process result. The exact time and pulse energy per individual pulse can be set due to the linear slab amplification. Particularly in combination with a scanner, this function can provide equidistant pulses on the workpiece even in the case of acceleration or deceleration.

In the event of an error, TRUMPF service experts will remotely access your laser via a secure remote connection. In many cases the fault can be remedied directly in this way, or the configuration of the laser can be modified in a way that permits you to continue manufacturing until the spare part arrives.

Interfaces are key for the integration of a TruMicro laser into your machine or production line. The solid-state lasers from TRUMPF offer interfaces to all common fieldbus systems. Also available: real-time interface, parallel digital I/O, interface for process sensor systems, OPC UA software interface, analog input board, interface for intelligent TRUMPF optics (CFO, PFO).

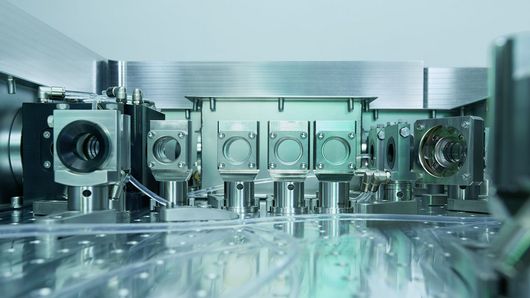

TOP Cleave cutting optics

The TOP Cleave-2 focusing optics are processing optics for high-dynamic cutting of transparent materials, such as glass or sapphire.

TOP Weld processing optics

The innovative processing optics for welding transparent materials without intermediate layers.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.