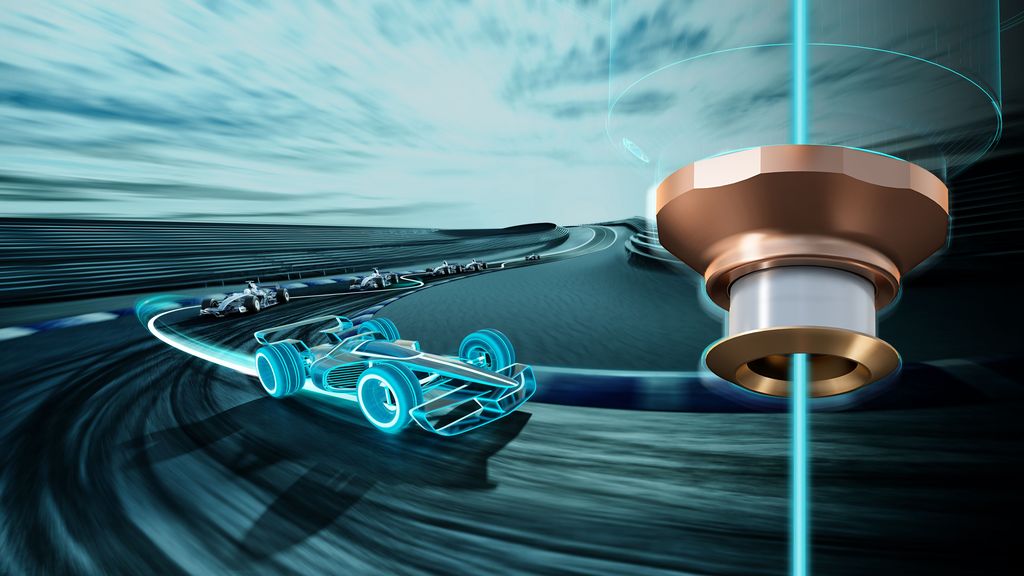

Solution

Big claims fulfilled by a small part: the Highspeed Eco nozzle from TRUMPF. Custom Laser saves up to 70 percent cutting gas with Highspeed Eco. The modularly constructed nozzle with its patented design is a top scorer: its casing glides so closely along the material that hardly any cutting gas can escape and reaches the kerf directly. This reduces the gas pressure needed to free the kerf from molten material by up to 60 percent. Compared to standard procedures, the feed rate in fusion cutting with Highspeed Eco is also twice as high at times and the results are optimum: smooth, uniform edges, minimal oxidation at the bottom and significantly reduced burr formation even with sharp corners.

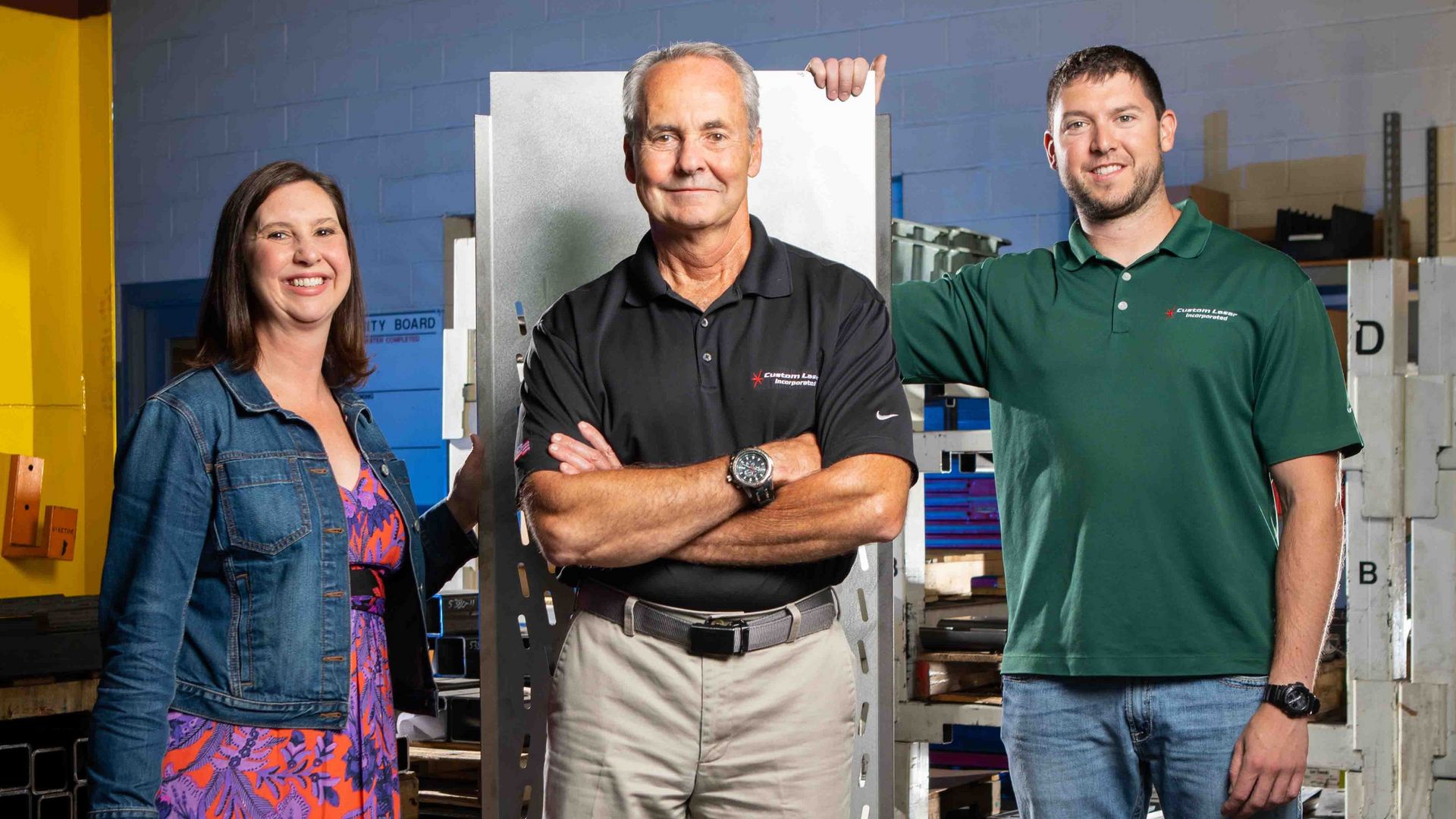

Implementation

Custom Laser's upgrade of the TruLaser 5030 fiber with the new Highspeed Eco nozzle only took one working day altogether, but will have a lasting impact for the American company. The innovative cutting procedure made it possible for Custom Laser to cut thicker carbon and stainless steel much faster – in some cases more than 250 centimeters a minute. In addition, control of the pierced holes has improved compared to when using oxygen for carbon steel.