Challenges

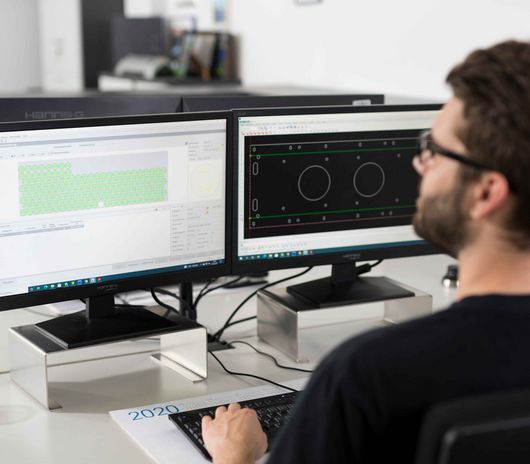

Rolf Lasertechnik focuses on speed and efficiency. Speed is guaranteed with state-of-the-art laser cutting machines from TRUMPF. However, the previously extensive sorting of laser-cut parts was a bottleneck that really slowed processes down. Sheets containing up to 20 different nested customer orders with up to 60 various components presented a real challenge for operators. Up to now, programmers made part removal easier by printing the views from the nesting program and marking all the parts from the same order with colored highlighters. "This preparation took up so much time and yet we still had to reckon with a certain error rate," explains Rolf and adds with a grin, "after all, to err is human, and humans were doing the work."