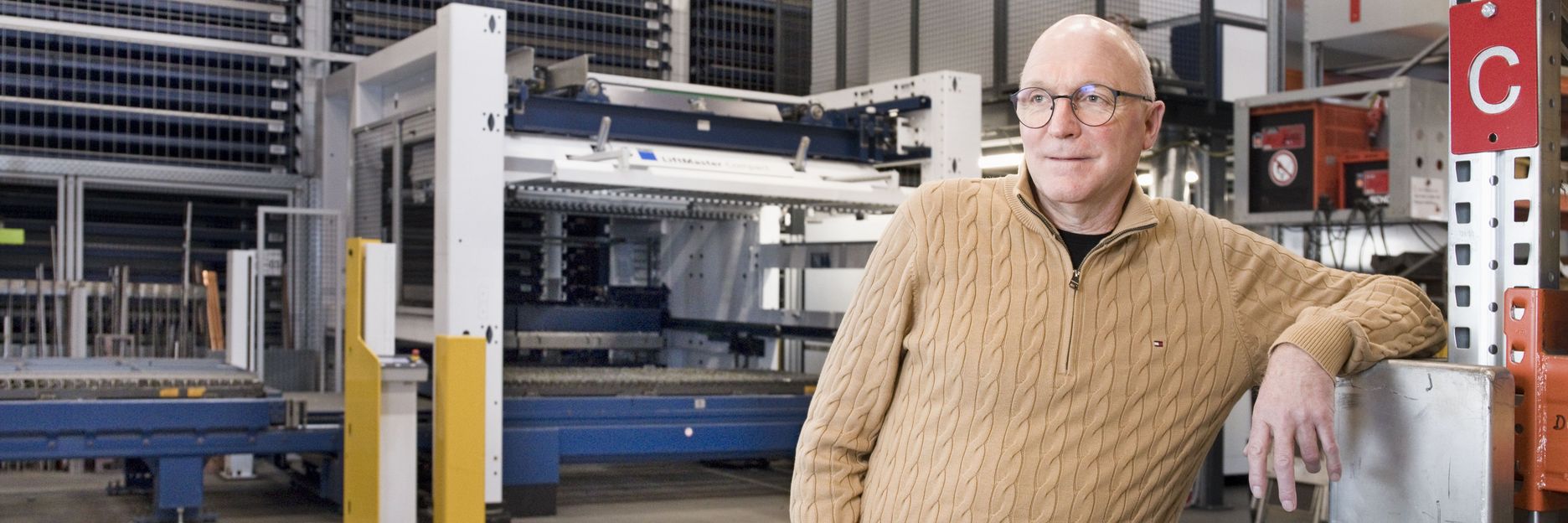

Krämer Brennteile is a classic job shop operation with around 40 employees based in Hofstetten, in the Black Forest. The team manufactures whatever is needed at the time – from delicate formed parts to 50-millimeter-thick gear plates. Hardly any series production takes place. Instead, numerous, mostly urgent small orders are produced as and when they are required. "We are fast, reliable and flexible – that’s our trademark," explains Managing Director Martin Krämer.

More power, more possibilities

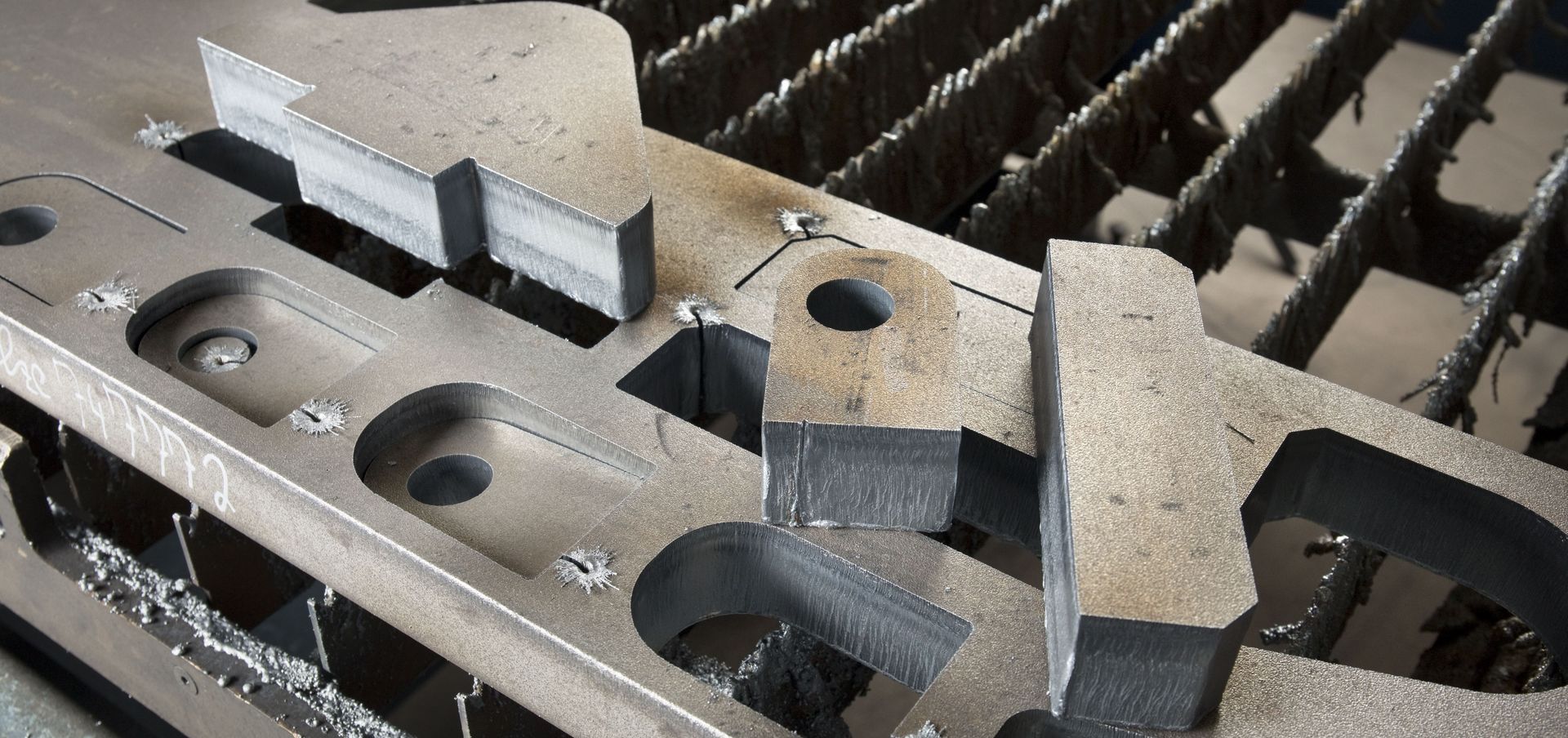

"We have made a name for ourselves with flame cutting," says Krämer. But he also knows that high-performance laser systems are in no way inferior to flame cutting when it comes to cutting thick materials and recognizes the potential for his company. He was considering purchasing the TRUMPF TruLaser 5030 laser cutting system, which offers an impressive full 24 kW of laser power. "We have customers who need components with threaded holes up to 50-millimeters thick. After flame cutting, we previously had to mill these parts, which was a time-consuming process. With the 24 kW machine, we can get all this done with just one tool setup," he says. He plans to use this new addition to expand his range of services. He therefore approached Felix Kuster, Regional Sales Manager at TRUMPF.

Consulting with vision

When Kuster talked to Krämer about the machine, he once again brought up the topic of automation, but as in previous visits, Krämer remained skeptical: "I truly believed that it wouldn't work for us – that it would be too inflexible, too costly." Like many others, Krämer believed that automation only makes sense for larger series production. Aside from the issue of space, he feared that automated processes would make him less flexible in his work. "You can't just slip in a small order at short notice, as we always have done," he explains. But this time Kuster persisted: The high productivity of the 24 kW laser will further accelerate loading and unloading – thereby putting existing processes under pressure. Krämer's employees were already at their limit when it came to handling the heavy sheets.

Kuster suggested a consultation with Markus Semrau, Technical Sales Manager Smart Factory at TRUMPF, and Krämer agreed. Semrau used the Smart Factory concept to analyze the entire process chain at Krämer's business – from material flow to part removal. It quickly became evident that excessive forklift traffic, narrow paths and numerous manual rearrangements were slowing down processes. Semrau showed that the higher machine output of the 24-kW system would further enhance operations.

"The machine's productivity only reaches its true potential when its surrounding environment is organized accordingly. Especially when space is limited, orderly processes and clear material flows are crucial," he summarized. Using figures, simulations and examples, he demonstrated how automation can shorten throughput times, enable night shifts and stabilize the material flow. Krämer's skepticism began to crumble.

An additional pallet for special orders

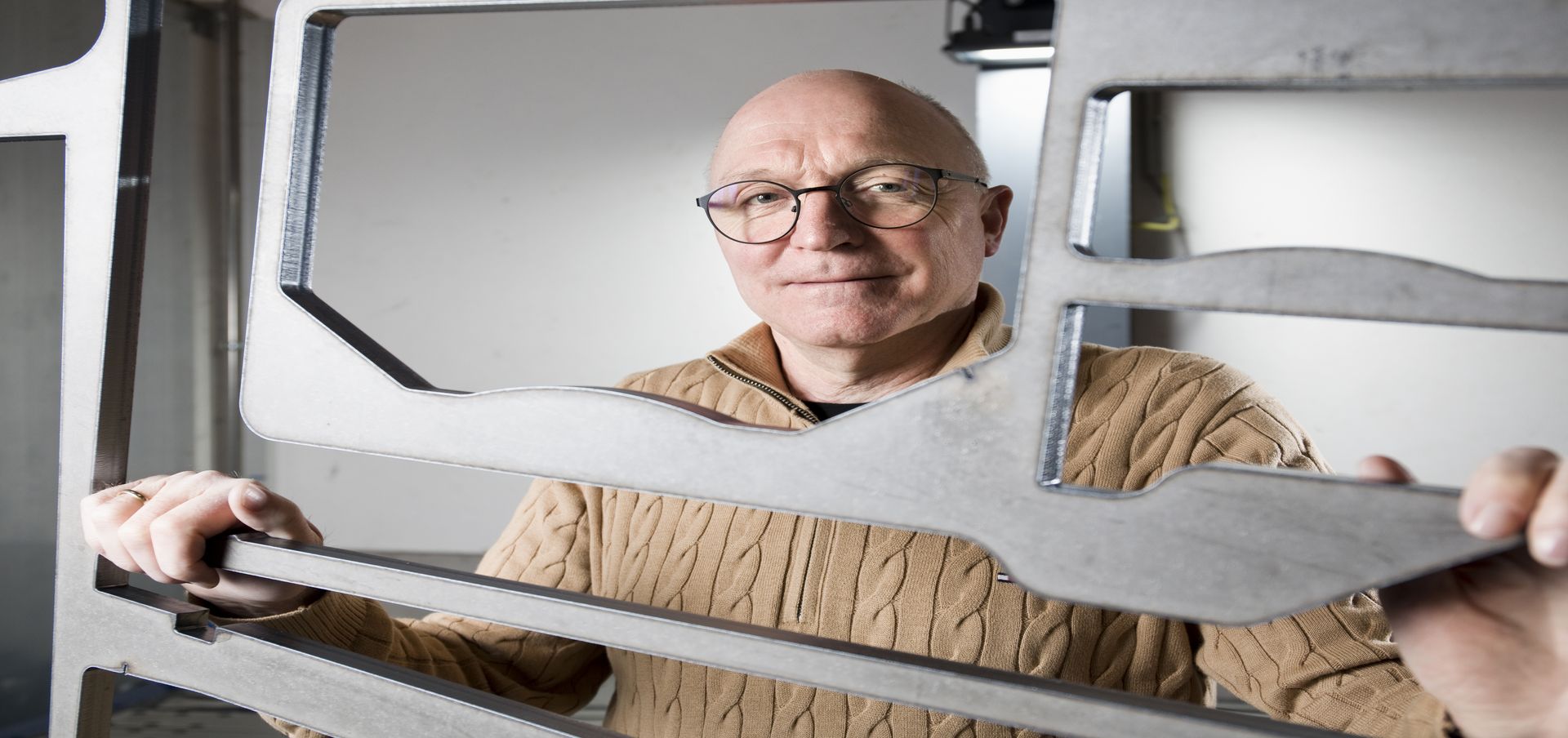

The decisive turning point was finally reached when TRUMPF experts proposed the attachment of an additional third pallet station to the laser system. This extension behind the machine is an additional loading and unloading station – in technical terms, a manually loadable buffer station that can be used independently of the automated storage system. In practice, it works as follows: While pallets one and two are being loaded or unloaded, the third pallet enters the machine and the order is cut. The additional pallet is loaded and unloaded manually or with the help of a crane. This allows urgent special orders or particularly thick sheets up to 50-millimeters thick to be literally "inserted" without disrupting the automated production flow.

"The third pallet is a real breakthrough," explains Semrau. "It combines the speed of an automated system with the accessibility of a stand-alone machine." Something which also won over Krämer – just ten weeks after the consultation, he decided to go with the automation package.

Improved speed, stability and safety

The 24-kW TruLaser 5030 Fiber is equipped with a LiftMaster Compact loading and unloading unit and connected to a STOPA storage system. Material logistics run digital and largely unmanned. Integrated inventory management ensures that the right sheet metal is available at the right time. There's no longer any need to search for materials and forklift traffic is minimized. This brings calm to production and increases workplace safety: No suspended loads and more ergonomic handling of large sheets.

The system has been operating automatically since it was commissioned. The difference is clearly noticeable: Clearly structured processes, less hectic work and more relaxed working conditions. "Previously, employees had to clear the table away as quickly as possible before the machine could continue working. Now everything runs automatically, which takes pressure off the processes," explains Krämer. The decision has already paid off for him in financial terms: Two operators per shift can now focus on other tasks, productivity has increased, and customers are delighted with the expansion of Krämer's product range.

Smart Factory on a small scale

For TRUMPF, the project is a prime example of how Smart Factory solutions can also work at smaller companies. "Automation doesn’t mean you have to rebuild an entire factory," says Semrau. "Often, intelligently linking existing processes is enough." Krämer has proven that digitalization and automation go hand in hand: The company has been working paperless for years with digitally managed production. The new system integrates seamlessly into this structure – and opens up new possibilities.

After all, there is space on the company premises for another factory section – the system is already designed to be mirrored. "I've certainly done a lot in recent years," he says. "My daughter will soon take over the business, and she should have the opportunity to develop it further." Once an automation skeptic , Krämer is a true convert. Ultimately, as he admits: "You simply have to experience it for yourself – then you can really understand the true benefits of automation."