Die besonders leistungsstarken Kurzpulslaser der TruMicro Serie 7000 tragen Schichten großflächig und schnell ab, bohren oder schneiden mit höchstem Durchsatz. Mit Pulsenergien von bis zu 100 mJ erreichen sie enorme Entschichtungsraten bei exzellentem Wirkungsgrad. Die Repetitionsrate der Laser können Sie bei gleichbleibender Pulsdauer variieren, um Ihre Bearbeitungsprozesse zu optimieren. Durch den Einsatz von Scannern lassen sich große Flächen besonders effizient abtragen.

Spezialist für große Flächen

Die Hochleistungs-Nanosekundenlaser der TruMicro Serie 7000 basieren auf der Scheibenlasertechnologie und kombinieren kurze Pulse und hohe Pulsenergien auch bei hohen Frequenzen. Damit sind die Laser für großflächiges und schnelles Reinigen, Abtragen oder Strukturieren mit höchstem Durchsatz bestens geeignet. Durch die flexible Strahlführung integrieren Sie den Laser mühelos in Ihre Fertigungsanlage.

Die ideale Kombination für Ihre Erfordernisse im Bereich der Mikrobearbeitung.

Reinigen oder tempern Sie auch großflächige Bauteile.

Die interne Leistungsregelung liefert uneingeschränkt die volle Pulsenergie für Ihren Prozess.

Die konfigurierbare Leistungs-Aufteilung ermöglicht eine optimale Anpassung an Ihre Anwendung.

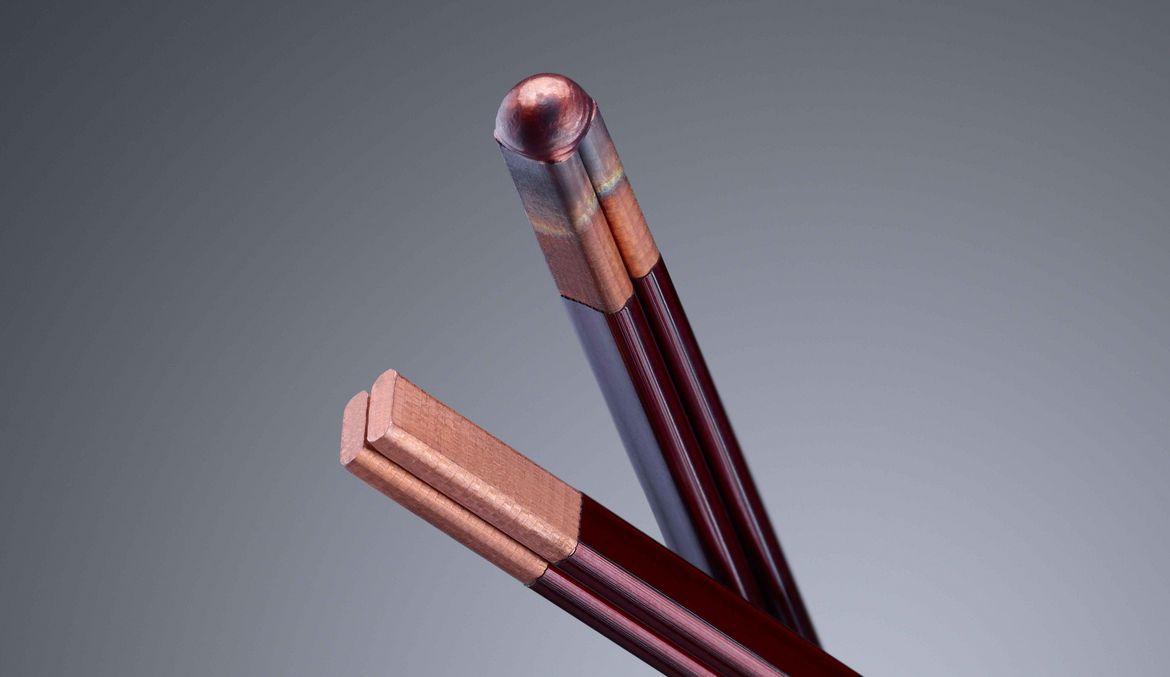

Entschichten empfindlicher Kupfer-Hairpins von Elektromotoren

Das empfindliche Kupfer der Hairpins von Elektromotoren wird durch eine Lackschicht vor Oxidation und Beschädigung geschützt. Um das Verschweißen der Pins vorzubereiten, wird die Lackschicht gezielt mit einem Kurzpuls-Laser entfernt, ohne das darunter liegende Kupfer zu beschädigen. Das Verfahren liefert dabei präzisere und schnellere Ergebnisse als mechanische Entschichtungs-Prozesse. Anschließend werden die Hairpins präzise verschweißt, um eine maximale Leitfähigkeit zu erreichen.

Hybride Verbindung aus Kunststoff und Metall

Um Verbrauch und CO2-Aussstoß ihrer Fahrzeuge zu senken setzen Automobilhersteller verstärkt auf Leichtbau. Dabei spielen hybride Metall-Kunststoff-Verbindungen zunehmend eine wichtige Rolle da sie beispielsweise die hohe Festigkeit und Steifigkeit von Metallen mit dem geringen Gewicht und der großen Designfreiheit von Kunststoff vereinen. Die Hochleistungs-Nanosekundenlaser der TruMicro Serie verbinden Metall und Kunststoff passgenau und ohne zusätzliches Material wie Schrauben, Nieten oder Kleber.

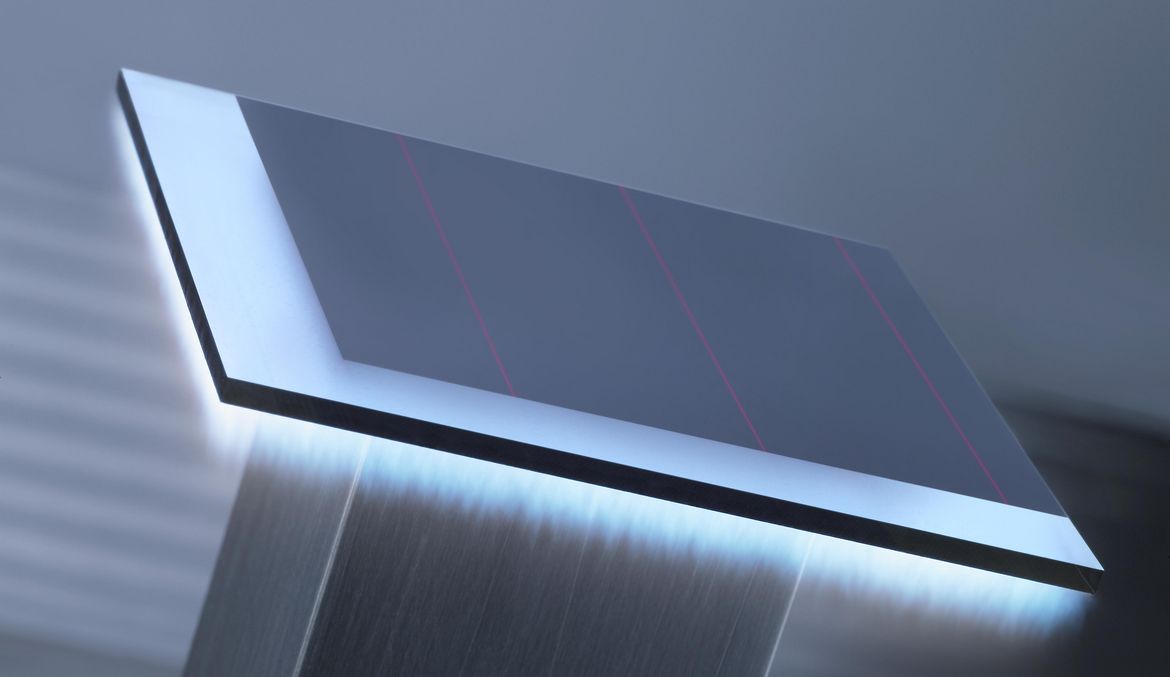

Randentschichten von Dünnschichtsolarmodulen

Um Dünnschichtsolarmodule vor Korrosion und Langzeitkurzschlüssen zu schützen, wird das Schichtsystem am Rand der Module entfernt und anschließend laminiert. Der Laser durchdringt bei dieser Anwendung das Glas und sprengt das Schichtsystem vom Trägermaterial ab, ohne Risse oder Aufschmelzungen auf dem Glas zu verursachen. Im Vergleich zum konventionellen Sandstrahlen fallen keine Kosten für das Strahlmittel und dessen Entsorgung an. Außerdem gewährleisten die ausgezeichneten Prozesseigenschaften extrem hohe Entschichtungsraten.

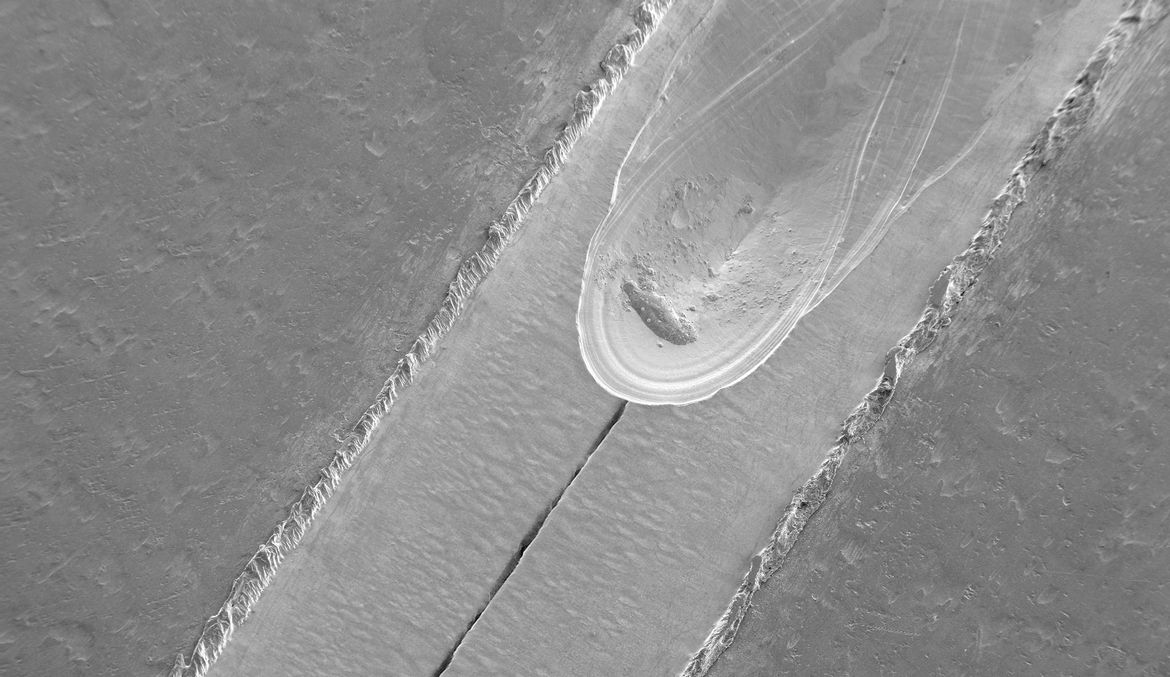

Schweißvorbereitung von AlSi-beschichteten Stahlblechen

Die Nanosekundenlaser der TruMicro Serie 7000 eignen sich optimal für den effizienten Abtrag von Aluminium-Silizium-Beschichtungen – ohne Änderung des Grundmaterials. Gerade in der Automobilindustrie werden Stähle mit Aluminium-Silizium (AlSi) als Antikorrosionsmittel beschichtet. Für optimale Schweißergebnisse muss diese Beschichtung im Bereich der Schweißnaht entfernt werden.

Reinigen und Lackabtrag mit Kurzpulslaser

Mit dem Kurzpulslaser lassen sich Lacke, Klebereste oder Oxidschichten partiell oder vollflächig von Oberflächen entfernen, ohne das Grundmaterial zu schädigen. Insbesondere in Bezug auf die Kanten- und Abtragsqualität wird der Laser den ästhetischen Ansprüchen seiner Nutzer gerecht, aber auch im Bereich Kosteneffizienz kann der Laserprozess mit konventionellen Verfahren konkurrieren.

|

TruMicro 7060

|

TruMicro 7070

|

|

|---|---|---|

| Laserparameter | ||

| Mittlere Ausgangsleistung | 1000 W | 2000 W |

| Strahlqualität | 10 mm▪mrad , abhängig vom verwendeten Laserlichtkabel | 10 mm▪mrad , abhängig vom verwendeten Laserlichtkabel |

| Wellenlänge | 1030 nm | 1030 nm |

| Pulsdauer | 30 ns | 30 ns |

| Max. Pulsenergie | 100 mJ | 100 mJ |

| Min. Repetitionsrate | 5 kHz | 5 kHz |

| Max. Repetitionsrate | 100 kHz | 250 kHz |

| Min. Durchmesser Laserlichtkabel | 300 μm | 300 μm |

| Bauform | ||

| Abmessungen bei Gerätegröße basic (B x H x T) | 1340 mm x 1430 mm x 725 mm | 1340 mm x 1430 mm x 725 mm |

| Abmessungen bei Gerätegröße Extended (B x H x T) | 1340 mm x 1475 mm x 1040 mm | 1340 mm x 1475 mm x 1040 mm |

Die technischen Daten aller Produktvarianten als Download.

TruControl

TruControl ist die schnelle und einfach bedienbare Steuerung für TRUMPF Festkörperlaser. Sie regelt die Laserleistung in Echtzeit für reproduzierbare Ergebnisse. TruControl verwaltet, steuert und visualisiert die Schnittstellenbelegung. Sie profitieren von einer einheitlichen Steuerungsarchitektur über alle Lasertechnologien hinweg. Die Laser verfügen über Schnittstellen zur Ansteuerung von intelligenten TRUMPF Optiken, z.B. der überwachten Fokussieroptik CFO oder der Scanneroptik PFO. Die Programmierung der Bearbeitungsoptik erfolgt bequem über die Lasersteuerung. Mit der TelePräsenz von TRUMPF erhalten Sie außerdem Support in wenigen Sekunden per Fernwartung. Dadurch können Serviceeinsätze verhindert oder bestmöglich vorbereitet werden und die Verfügbarkeit des Lasergeräts steigt.

Mit Zusatzoptionen arbeiten Sie noch effizienter und prozesssicherer mit den Hochleistungs-Nanosekundenlasern der TruMicro Serie 7000.

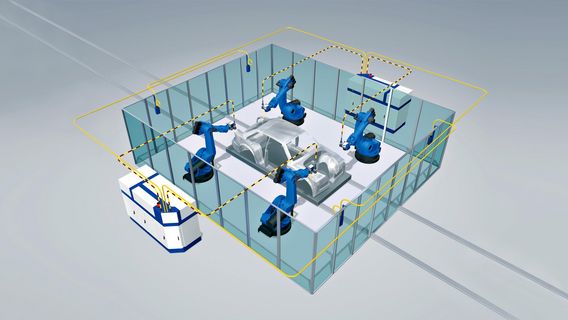

Um flexibel mit Ihrem Laser planen zu können, haben Sie eine Vielzahl an Möglichkeiten bei der Strahlführung. Per Plug & Play schließen Sie Laserlichtkabel ganz einfach an verschiedene Arbeitsstationen an. Sie wählen dabei die verwendete Anzahl der bis zu vier Faserabgänge. Die Laserleistung regulieren Sie pro Abgang. Mehrere Arbeitsstationen arbeiten so gleichzeitig mit geteilter Laserleistung oder nacheinander mit voller Laserleistung. Dieses Aufteilen können Sie dank der modularen Systematik sogar nachrüsten.

Im Lasernetzwerk vernetzen Sie einen oder mehrere Laser mit jeweils bis zu vier Arbeitsstationen. Ihr Laser teilt dabei entweder seine Leistung auf mehrere Stationen auf oder versorgt sie mit voller Kraft abwechselnd. Das erlaubt Ihnen sogar, unterschiedliche Anwendungen miteinander zu kombinieren.

Über eine eigene Schnittstelle synchronisieren Sie intelligente Optiken mit Ihrem Laser. So können Sie etwa die Fokussieroptik CFO oder die Scanneroptik PFO optimale für Ihre Zwecke nutzen. Die Programmierung der Bearbeitungsoptik erfolgt bequem über die Lasersteuerung. Ein zusätzlicher PC oder Steuerungen sind nicht notwendig.

Im Störungsfall greifen TRUMPF Serviceexperten über eine sichere Remote-Verbindung aktiv auf Ihren Laser zu. Häufig wird so die Störung direkt behoben oder die Konfiguration des Lasers so verändert, dass Sie bis zum Eintreffen des Ersatzteils weiter produzieren können.

TRUMPF bietet Ihnen alle Komponenten, die Sie zur Strahlführung vom Laser bis zum Werkstück benötigen. So auch diverse Fokussieroptiken, die sich in vielen Jahren industriellen Einsatzes als präzise und zuverlässig bewährt haben. Die Optiken sind leicht integrierbar – sowohl in Stand-Alone-Bearbeitungsstationen als auch in kompletten Fertigungslinien. Der modulare Aufbau ermöglicht es die Optiken stets an den Lasertypen sowie an die unterschiedlichen Bearbeitungssituationen anzupassen.

Fokussieroptiken

Ob beim Schweißen, Schneiden, Abtragen, Aufheizen oder Bohren: Mit robusten Festoptiken von TRUMPF erreichen Sie hochwertige Prozessergebnisse!

Programmierbare Fokussieroptiken

Die idealen Optiken für die Remotebearbeitung

Je nach Land sind Abweichungen von diesem Produktsortiment und von diesen Angaben möglich. Änderungen in Technik, Ausstattung, Preis und Zubehörangebot sind vorbehalten. Bitte setzen Sie sich mit Ihrem Ansprechpartner vor Ort in Verbindung, um zu erfahren, ob das Produkt in Ihrem Land verfügbar ist.