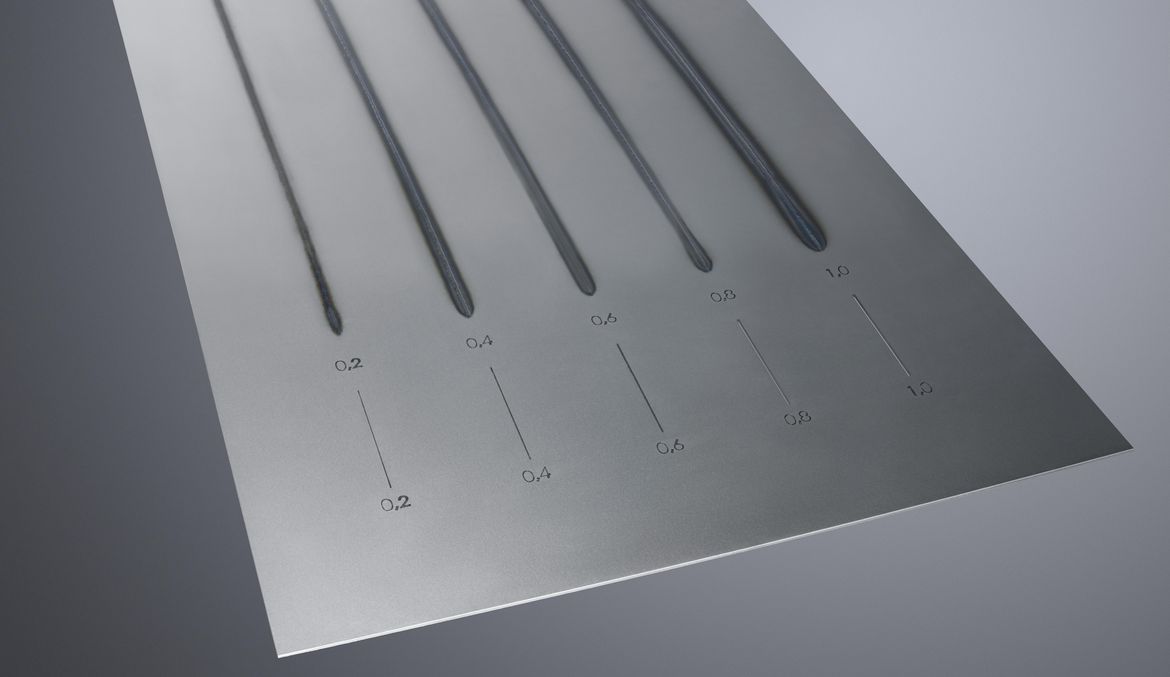

Mit dem neuen Schweißprozess BrightLine Scan schweißen Sie robust und flexibel kleine Fügespalte, stellen Nahtbreiten gezielt ein und beeinflussen die Nahtschuppung. Heben Sie Ihr Laserschweißen auf ein neues Niveau und erschließen Sie neue Anwendungsfelder, z.B. in dickem Blech und Aluminium und reduzieren Sie Spritzer.

Ein System, unzählige Vorteile

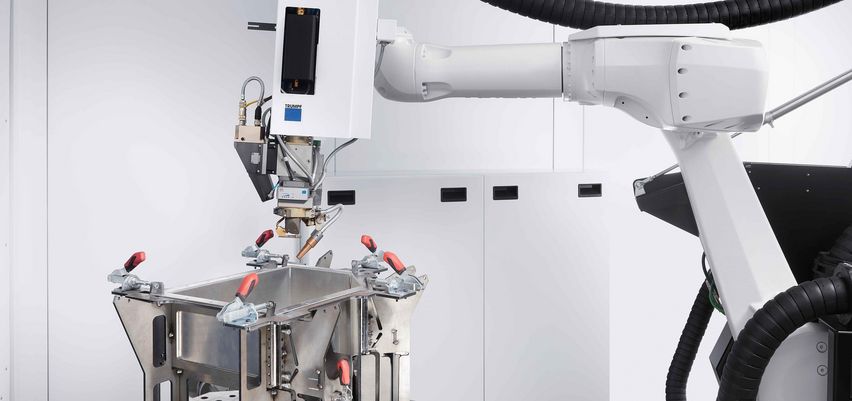

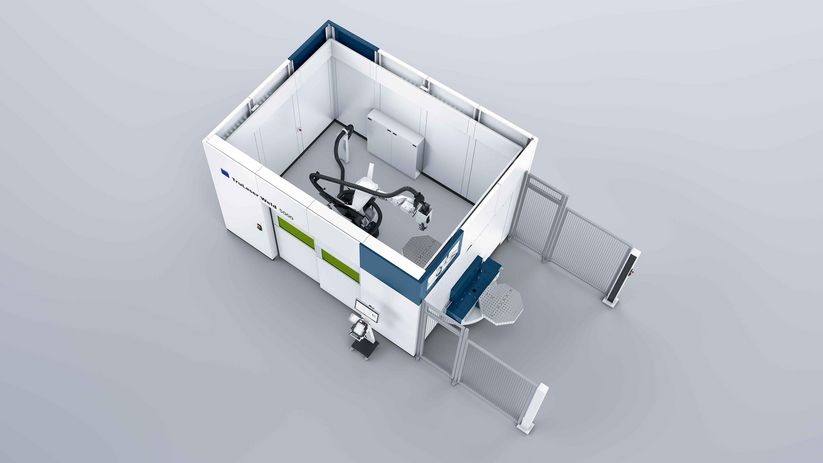

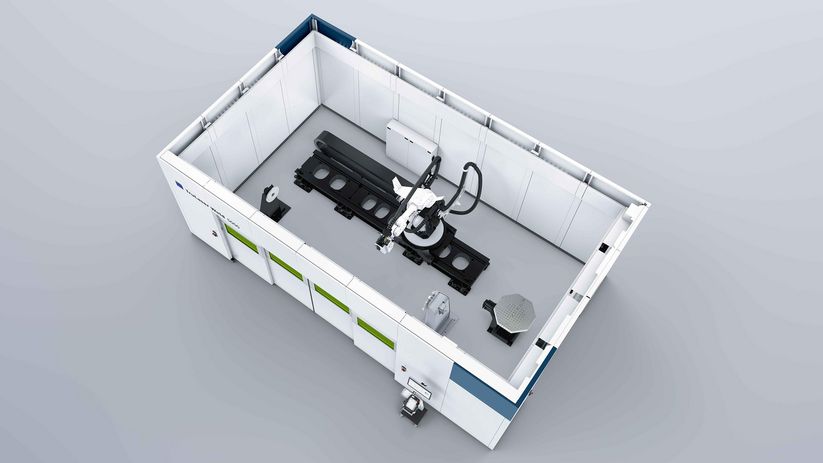

Roboter, Laser, Bearbeitungsoptik, Schutzkabine und Positioniereinheiten: TruLaser Weld 5000 ist ein schlüsselfertiges System für das automatisierte Laserschweißen. In einem System schweißen Sie flexibel tiefe und feste Nähte oder schön abgerundete, glatte Nähte. Dank FusionLine verbinden Sie auch Bauteile mit Spalten. Die vielseitige Anlage passen Sie mit unterschiedlichen Bauteilpositionierern zudem genau an Ihre Bedürfnisse an.

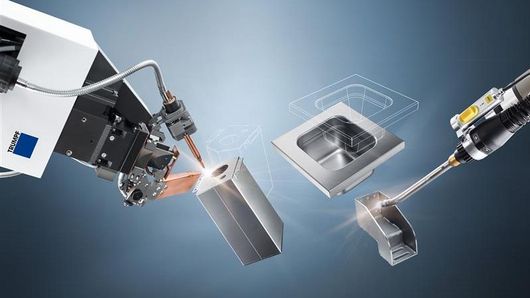

Auf nur einer Maschine: Wärmeleitschweißen, Tiefschweißen oder FusionLine

Funktionen wie das schwenkbare Bedienpult und der zusätzliche Statusmonitor erleichtern die Arbeit.

Sehr gute Teilezugänglichkeit durch das Drehmodul für Schutzgasführung

Je nach gewünschter Beladeoption stehen unterschiedliche Bauteilpositionierer zur Verfügung.

Mit der einfachen Offline-Programmiersoftware TruTops Weld

Das Sensorsystems TeachLine erkennt zuverlässig die Platzierung der Naht.

Prozesssicher schweißen

Mit BrightLine Scan schweißen Sie Ecken, Spalten und weitere Toleranzen prozesssicher. Dieses Musterteil aus Baustahl zeigt eine konventionell gestaltete Abdeckhaube für eine Spannpratze.

Hochwertige Schweißergebnisse

Die hohen Frequenzen von BrightLine Scan erzielen hochwertige Schweißergebnisse bei Aluminiumlegierungen. Dieses Musterteil aus Aluminium zeigt ein Batteriewannen-Element mit 135° Ecke.

Flexibel schweißen

Der Wassertank aus Edelstahl zeigt verschiedene tiefgeschweißte Nahtgeometrien in Blechdicken von 1,5 und 3 mm.

Schnell und sicher

Mit dem Tiefschweißverfahren erzeugen Sie schnell schlanke Nähte von hoher Festigkeit.

Nahezu unsichtbar

Das Thekensegment aus Edelstahl brilliert dank Wärmeleitschweißen mit besonders schönen Sichtnähten.

Für alle gängigen Materialien

Der untere Klemmenkasten besteht aus Baustahl, der mittlere aus Edelstahl und der obere aus Aluminium. Alle Materialien schweißen Sie flexibel mit dem Laser.

Wie aus einem Guss

Mit Wärmeleitschweißen erzeugen Sie schön abgerundete Nähte, fast ohne Bauteilverzug.

Kaum Nacharbeit

Der Gastronomiebehälter aus Edelstahl lässt sich mit Laserschweißen nahezu ohne Nachbearbeitung fertigen.

Tolerantes Laserschweißen

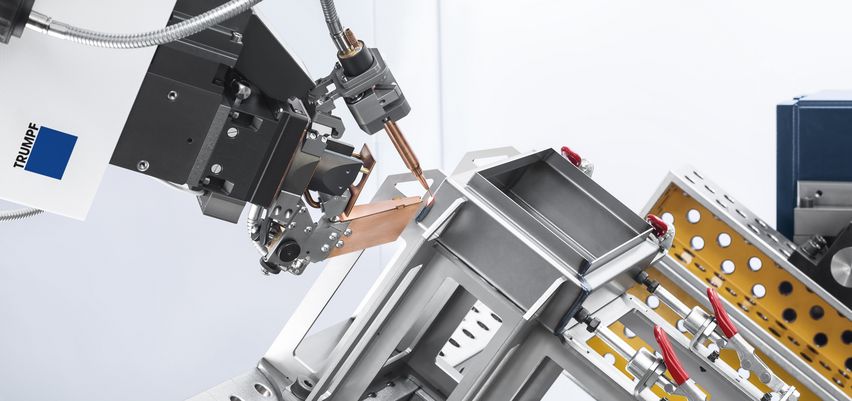

Das neue FusionLine überbrückt Spalte bis zu einem Millimeter Breite.

|

TruLaser Weld 5000

|

|

|---|---|

| Achsdaten | |

| Typ | High-Accuracy-Roboter |

| Anzahl der Achsen | 6 |

| Nenn-Traglast | 70 kg |

| Wiederholgenauigkeit | +/- 0,05 mm |

| Laserspezifische Daten | |

| Verfügbare Laser | TruDisk 4001 / 6001 / 8001 | TruFiber 3001 / 4001 / 6001 |

| Dreh-Kipp-Positionierer | |

| Max. Arbeitsraum | 2000 mm x 1000 mm x 1200 mm |

| Max. Beladung | 500 kg |

| Drehtisch | |

| Max. Arbeitsraum | ⌀ 2350 mm x 1150 mm |

| Max. Beladung (pro Seite) | 250 kg |

| Rotationswechsler | |

| Max. Arbeitsraum | ⌀ 1200 mm x 2600 mm |

| Max. Beladung (pro Seite) | 750 kg |

| Rotationswechsler mit Wendeachse | |

| Max. Arbeitsraum | ⌀ 1200 mm x 2600 mm |

| Max. Beladung | 750 kg |

| Wendepositionierer | |

| Max. Arbeitsraum | ⌀ 2000 mm x 4000 mm |

| Max. Beladung | 1000 kg |

| Kompakter Rotationswechsler mit 3D Aufspannplatte (Rechteck) | |

| Max. Arbeitsraum (⌀) | 3000 mm |

| Max. Arbeitsraum (Höhe) | 1250 mm |

| Max. Beladung (pro Seite) | 600 kg |

| Max. Lastmassenträgheitsmoment | 600 kg*m2 |

| Drehbereich Rotationswechsler | ± 180 ° |

| Drehzeit Rotationswechsler (für 180°) | 3,7 s |

| Einlegehöhe | 830 mm |

| kompakter Rotationswechsler mit vertikalen Drehachsen | |

| Max. Arbeitsraum (⌀) | 3000 mm |

| Max. Arbeitsraum (Höhe) | 1250 mm |

| Max. Beladung (pro Seite) | 600 kg |

| Max. Lastmassenträgheitsmoment Ringrundschalttisch | 600 kg*m2 |

| Drehbereich Rotationswechsler | ± 180 ° |

| Drehzeit Rotationswechsler (für 180°) | 3,7 s |

| Drehbereich vertikale Drehachsen | ± 190 ° |

| Drehzeit vertikale Drehachsen (für 180°) | 2,5 s |

| Max. Lastmassenträgheitsmoment vertikale Drehachsen | 359 kg*m2 |

| Einlegehöhe | 885 mm |

| Maße, Gewichte | |

| Mögliche Kabinenabmessungen |

4800 mm x 3650 mm x 3215 mm

4800 mm x 4800 mm x 3215 mm 4800 mm x 5950 mm x 3215 mm 5950 mm x 4800 mm x 3215 mm 5950 mm x 5950 mm x 3215 mm 7100 mm x 4800 mm x 3215 mm 7100 mm x 5950 mm x 3215 mm 8250 mm x 4800 mm x 3215 mm 8250 mm x 5950 mm x 3215 mm 9400 mm x 4800 mm x 3215 mm 9400 mm x 5950 mm x 3215 mm |

Die technischen Daten aller Produktvarianten als Download.

Mit einer in die Robotersteuerung integrierten NC-Rundachse macht der Dreh-Kipp-Positionierer auch schwer zugängliche Bauteile in nur einer Aufspannung schweißbar.

Mit dem Drehtisch rüsten Sie während des Schweißvorgangs außerhalb der Zelle, was die Effizienz Ihrer Anlage steigert.

Kompakt, produktiv und preiswert: Mit dem automatisch drehbaren Schweißtisch verdoppeln Sie Ihren Durchsatz und können auf einer Tischseite innen schweißen und gleichzeitig außen ein neues Bauteil rüsten.

Kompakt, flexibel und wirtschaftlich: Steigern Sie Ihre Flexibilität und Zugänglichkeit zum Bauteil durch die vertikale Drehachse.

Schnell, flexibel und massiv: Profitieren Sie von der hohen Traglast, der großen Spitzenweite und schnellen Drehzeit. Das ist optimal für eine zügige "Rund-um-die-Uhr-Bearbeitung" hoher Stückzahlen und großer Bauteile.

Der Roboter der TruLaser Weld 5000 fährt entlang einer Linearachse und deckt auf diese Weise einen großen Arbeitsraum ab. Passend dazu verfügt die Anlage über einen vier Meter langen Wendepositionierer.

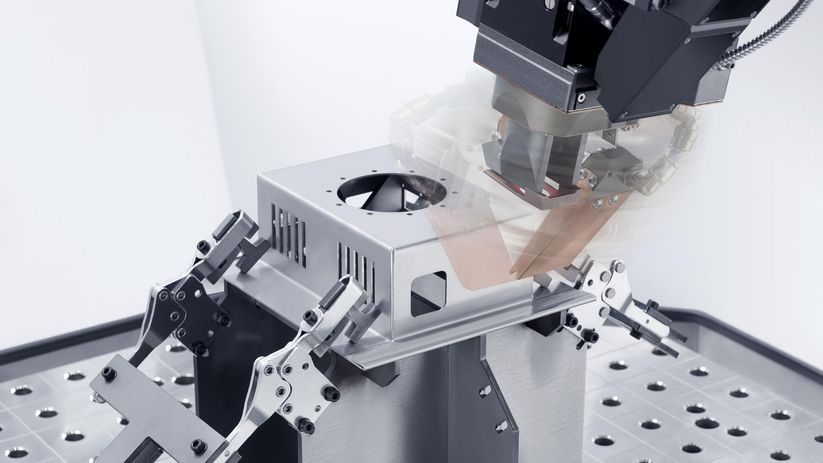

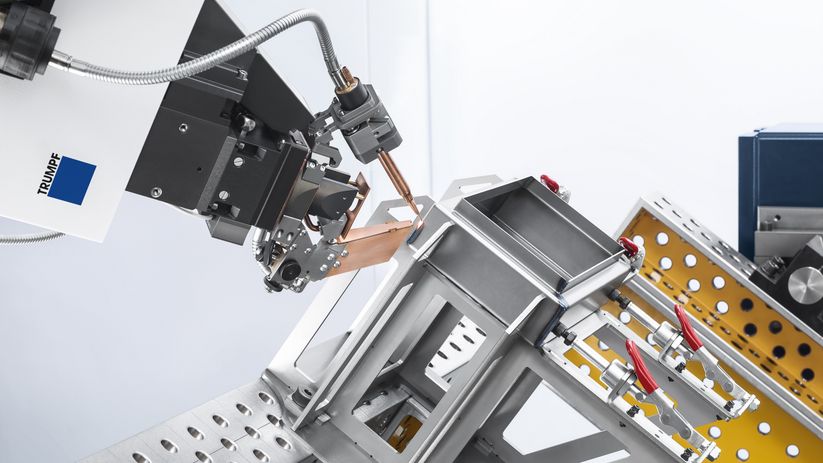

Die Schutzgasdüse dreht sich stufenlos um die Optik herum. Der Roboter muss sich deutlich weniger umorientieren. Das reduziert Ihren Aufwand für Spanntechnik und Programmierung, macht Ihre Bauteile besser zugänglich und Sie schweißen deutlich schneller.

Dank des Sensorsystems TeachLine schweißen Sie Bauteile auch ohne zeitintensives Nachteachen. Die Sensoren erkennen die Platzierung der Naht, selbst wenn deren Ist-Position leicht von der Soll-Position abweicht.

Mit FusionLine können Sie Spalte bis zu 1 mm Breite schließen und wirtschaftlich laserschweißen, ohne Ihr Bauteilportfolio für das Laserschweißen zu optimieren.

Bei diesem neuen Schweißprozess mit Strahloszillation bewegen zwei programmierbare Spiegel den Laserstrahl. Dabei sorgen Frequenzen bis 2000 Hz für einen äußerst robusten und flexiblen Schweißprozess. Heben Sie Ihr Laserschweißen auf ein neues Niveau.

Mit dem Nullpunktspannsystem können Sie Vorrichtungen schnell und präzise anbringen. Es bietet passende Systeme für Dreh-Kipp-Positionierer und Rotationswechsler.

Die nahtlose Integration vieler Maschinen von TRUMPF in die eigene Softwarewelt ist problemlos und einfach. Sei es eine Integration in Oseon oder eine Anbindung an Monitoring und Analyse Tools - für jede Kombination stellen wir die passende Lösung bereit. Auch eine Anbindung an Software Systeme von Drittanbietern ist mit unseren Schnittstellen basierend auf dem OPC UA Standard möglich.

TruTops Weld

Erstellen Sie schnell und unkompliziert Ihr Schweißprogramm am Rechner mit der Offline-Programmiersoftware TruTops Weld und reduzieren so Nebenzeiten an Ihrer TruLaser Weld 5000.

Software

Von der Kundenanfrage bis zur Auslieferung des gefertigten Teils – das Software-Portfolio von TRUMPF optimiert Ihren kompletten Fertigungsprozess. TRUMPF kombiniert dabei die Software intelligent mit Maschinen und Services zu maßgeschneiderten Industrie 4.0-Lösungen für Ihre Smart Factory.

Je nach Land sind Abweichungen von diesem Produktsortiment und von diesen Angaben möglich. Änderungen in Technik, Ausstattung, Preis und Zubehörangebot sind vorbehalten. Bitte setzen Sie sich mit Ihrem Ansprechpartner vor Ort in Verbindung, um zu erfahren, ob das Produkt in Ihrem Land verfügbar ist.