Challenges: Market forces and modular machines

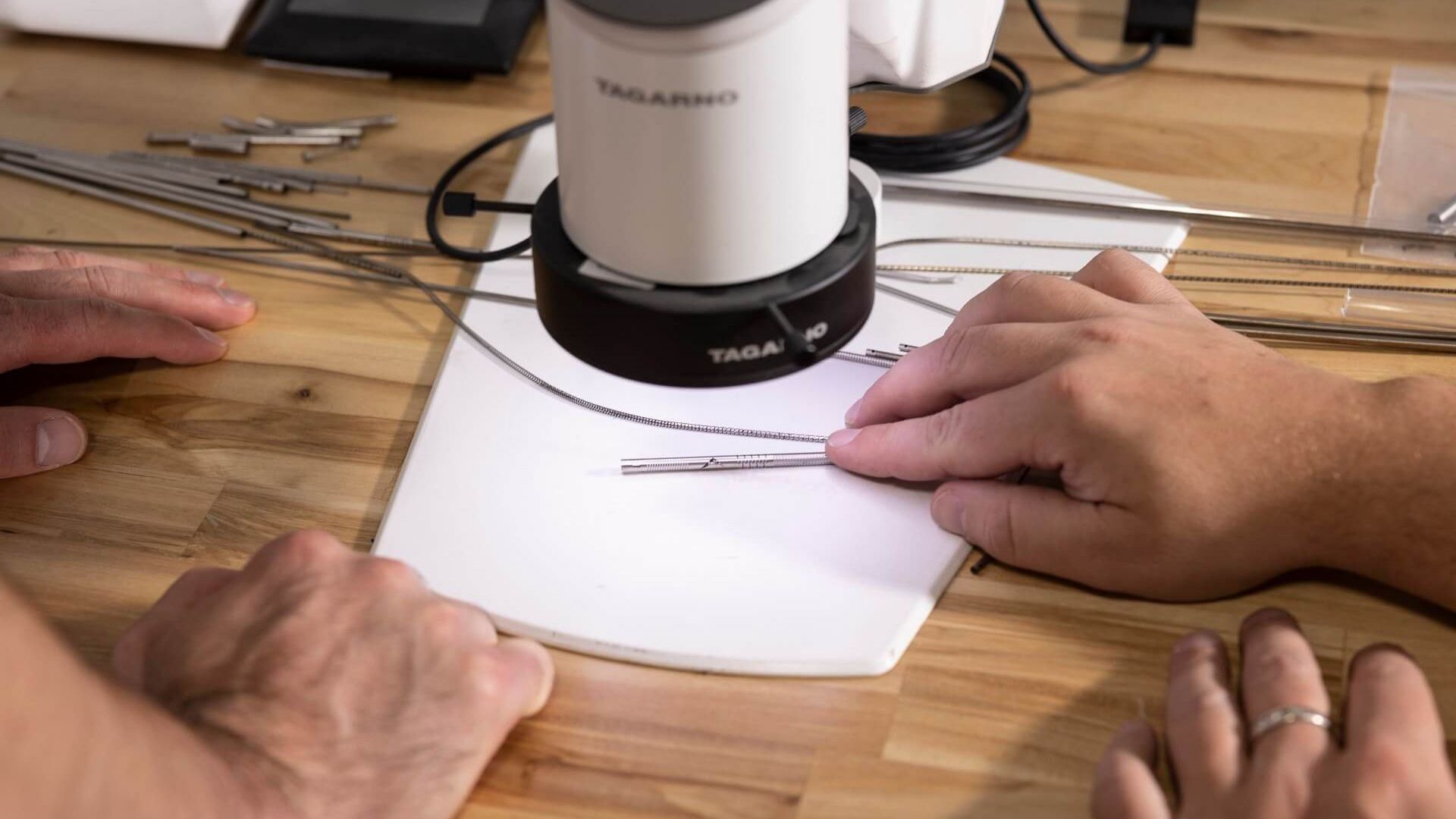

Joe Kempf wants to build micromachining machines and sell them to manufacturers of stents and similar tubes. The demand for these tubes is high and manufacturers cannot keep pace with their machines. However, market entry is strictly controlled by regulatory authorities worldwide. This is why the major manufacturers of stent cutting machines are splitting the market among themselves, thus creating a bottleneck because production and products are becoming outdated. Alpine Laser is working on machines that can meet demand faster and better than the established companies can. The design of such machines always involves a crucial compromise: on the one hand, the machine should be easily scalable and therefore affordable and fast to produce. On the other hand, it must remain individually customizable. Kempf: "We realized that only a modular system design could satisfy both objectives." And only a USP laser can achieve the quality and time savings required for this.