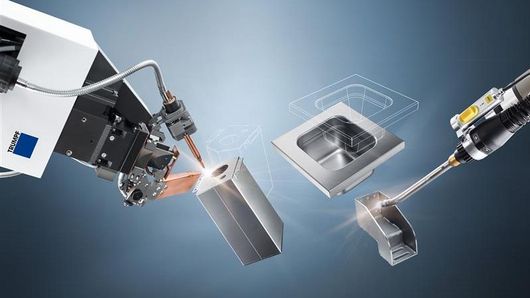

Laserschweißanlagen und Lichtbogenschweißzelle

Laserschweißanlagen von TRUMPF sind das ideale Werkzeug, wenn es darum geht, Metalle präzise zu schweißen. Dabei lassen sich sowohl Werkstoffe mit hohen Schmelztemperaturen als auch hohen Wärmeleitfähigkeiten optimal fügen. Die TRUMPF Lichtbogenschweißzelle macht dank schneller Programmierung und einfacher Bedienung einen leichten Einstieg ins automatisierte Schweißen möglich. Sie profitieren von höherer Produktivität und Qualität im Vergleich zu konventionellem Hand-Schweißen.

Beim Laserschweißen fertigen Sie nahezu verzugsfreie Werkstücke mit höchster Präzision. Optisch anspruchsvolle Schweißnähte benötigen kaum Nacharbeit. Gleichzeitig bieten unsere Anlagen hochproduktive Prozesse für große Stückzahlen bei hoher Wiederholgenauigkeit oder Flexibilität für wechselnde Losgrößen.

Beim Lichtbogenschweißen verwenden wir eine spezielle Schweißstromquelle von Fronius für automatisierte Anwendungen, welche zusätzlich das neue modifizierte Impulslichtbogenverfahren PMC (Pulse Multi Control) unterstützt. So sorgen präzise Schweißprozesse für beste Ergebnisse und Qualität.

Auf einen Blick: Welche Vorteile bringen Ihnen unsere Roboterschweißzellen?

Fachkräftemangel und steigende Qualitätsanforderungen stellen Unternehmen beim Schweißen vor große Herausforderungen. Erfahren Sie hier, wie wir Ihnen Roboterschweißen dabei helfen kann.