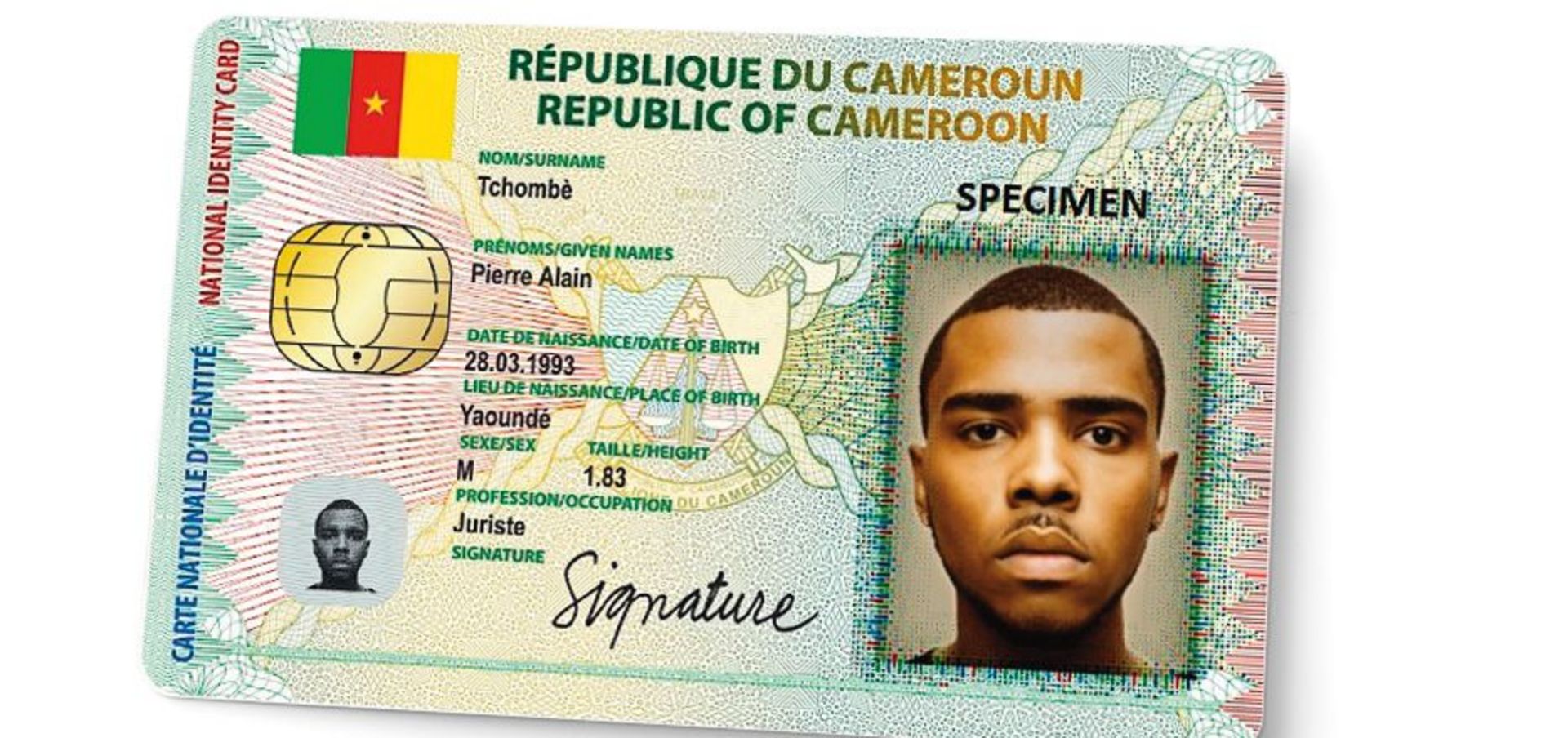

With a soft click the flap opens and a stack of plastic cards drops into the output tray. The operator retrieves the identity cards from the Color Laser Marking personalization system. It’s at the Délégation Générale à la Sûreté Nationale authority (DGSN) in Yaoundé, Cameroon’s capital.

The employee examines one of the cards, satisfied with the result. The reverse side features in warm colors a hilly landscape near to the village of Rhumsiki located in the Région de l’Extrême-Nord of Cameroon. The front bears the photo of the card’s future owner—the colors are vibrant, perfectly reflecting the original, and the image is razor-sharp.

Some 7,000 kilometres away, Joseph Leibenguth is sitting in his office in the French town of Meudon. He is Gemalto’s Secure Documents Director and explains enthusiastically that this technology is truly ground-breaking: “Previously, we had only been able to embed black and white images in the polycarbonate cards in such high resolution. We wanted to do the same with color images while still offering the same level of security—but without having to make any major changes to the production process.”

Leibenguth is Gemalto’s Secure Documents Director and helps to make identitiy document even more secure. He stresses: “Personal identity documents have to be completely tamperproof.”

Protection against forgery and misuse

Gemalto is a global provider of digital security systems and “Color in PC” is the group’s latest personalization solution for Identity Documents. Cameroon is the first country in to world to draw on the new technology. “Personal identity documents have to be completely tamperproof,” Leibenguth stresses. For this reason, the security technologies behind them are becoming increasingly intelligent. Integrated electronic chips containing biometric data such as the holder’s fingerprint are now standard. “By using lasers to embed the high-resolution color images into the cards, we can provide even higher levels of protection against forgery and misuse. The images can’t be manipulated and it’s easy to establish whether or not the person in possession of the document is really the same person as in the photo.”

Layers of intelligence

The structure of the plastic cards also provides, quite literally, added layers of security: “The final document is composed of five to seven polycarbonate layers,” Leibenguth explains. “The core layer is white and between 300 and 400 micrometers thick. It houses the data chip and the antenna that enables contactless reading of the chip’s contents.” The blank cards are manufactured at one of Gemalto’s global production sites. Since end users’ personal data may be stored or engraved on the cards only in their respective countries of residence, responsibility for the personalization stage lies with government printers and national authorities—or service providers like Gemalto acting locally on their behalf.

Three lasers, terrific image quality

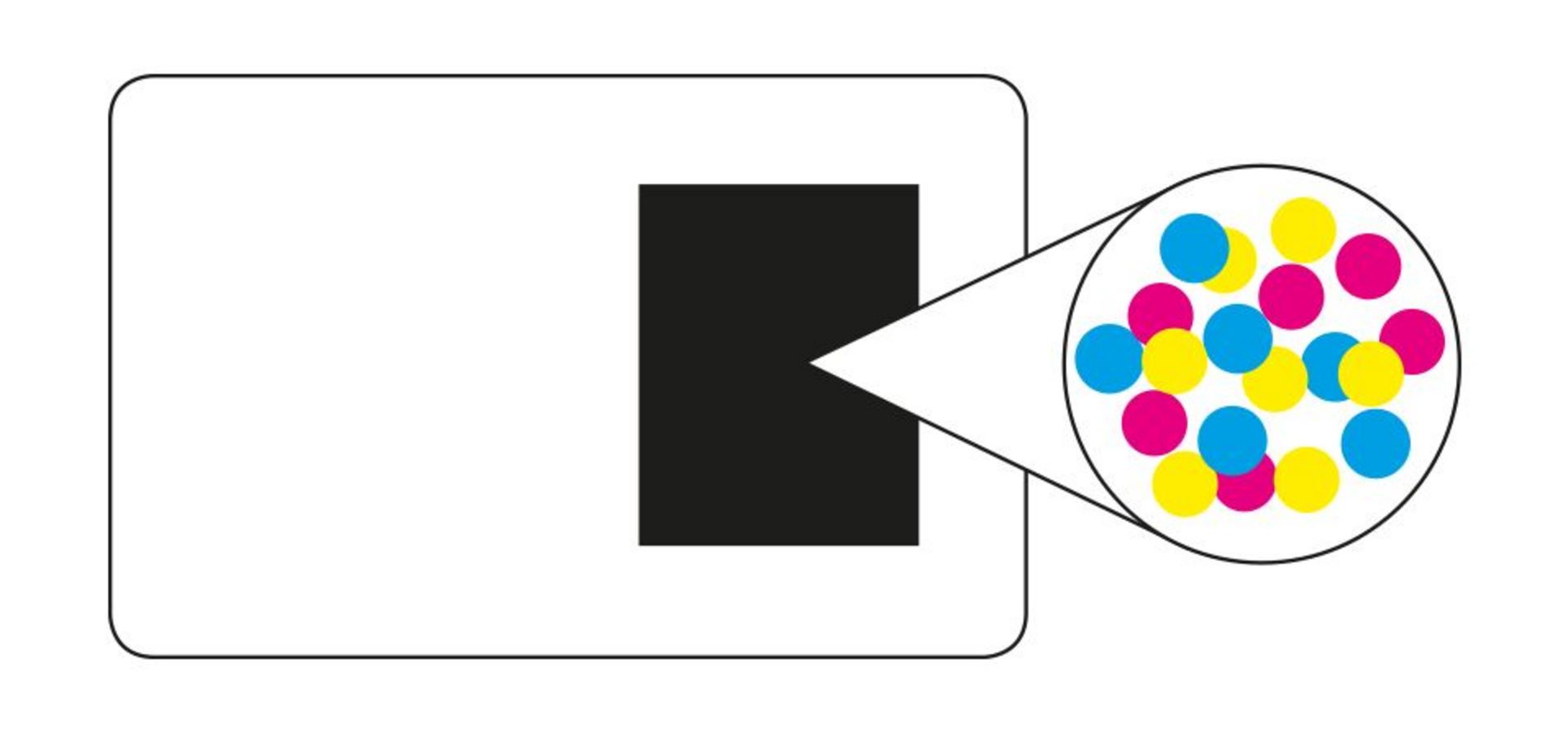

With its new laser engraving technology, Gemalto embeds color images in a special layer of the card. “The process involves working with a polycarbonate layer that contains photosensitive black ink composed of cyan, magenta and yellow pigments, also known as CMY,” says Leibenguth.

CMY serve as the “primary” colors in color printing, given that they can be mixed in different ways to make any other color. When combined, the CMY pigments make black.Red, green and blue (RGB) lasers are used to selectively bleach the individual pigments using their three different wavelengths. This is what creates the nuanced colors visible to the observer once the process is complete. The red, green and blue lasers bleach the cyan, magenta and yellow particles respectively. The result is a high-quality color image securely sealed in the polycarbonate body. “There’s no need to add ink during the personalization stage, as the black layer already contains all the pigments required to reproduce the color photo. It doesn’t require any additional consumables. That’s what makes our process so great,” emphasizes Leibenguth.

It’s all about the pulse

To make all this possible, however, Gemalto first needed an RGB laser capable of achieving exceptionally high pulse stability, an extremely important prerequisite. This was a task for the research and development experts at TRUMPF’s Laser Application Center (LAC) in Grüsch, Switzerland.

In a joint effort with Gemalto, they developed the pulsed solid-state lasers, which have beam diameters of 40 to 50 micrometers and are capable of delivering nanosecond pulses. For two of the three lasers, the developers had to halve the wavelength, and thus double the frequency. “Our focus was always on achieving a high pulse stability,” explains Andreas Conzelmann, General Manager at TRUMPF Laser Marking Systems AG in Grüsch. “Any variation of peak power of the pulses would immediately distort the colors.”

A power regulator ensures the required power and pulse stability. “The laser always functions at its ideal working level. The design we developed specifically for this application allows us to adjust the laser’s power extremely precisely from pulse to pulse—and a hundred thousand times a second,” explains Conzelmann.

Multitasking at top speed

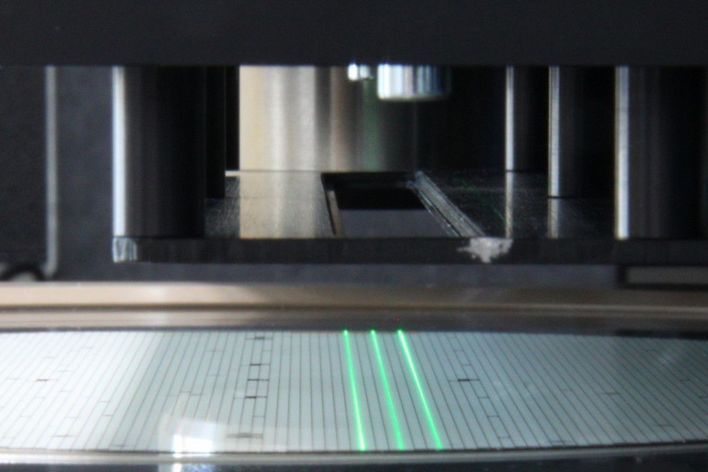

They got the technology working, but for it to be employed in Gemalto’s personalization systems, it was also required to achieve a very fast color bleaching processing time to deliver an extremely high throughput. The best strategy for placing laser points on the photo needed to be found—as well as simultaneously on multiple identity cards.

TRUMPF achieved this with its software. First, two infrared lasers work in parallel to mark information such as name, date of birth and signature in black on the front and reverse sides. Then the RGB lasers get to work. As soon as the red laser has finished bleaching the cyan pigment in one card the green laser takes over, while the red laser moves on to process the next identity card. “When the machine is running at full speed, five lasers are working simultaneously,” says Conzelmann. This is the case in Yaoundé, where the system is producing more than 1.2 million identity cards per year. Not only are they absolutely secure, they also look good.