Manufacturing sustainability and resource efficiency have become important topics for industry and research. New legal requirements such as the EU’s Ecodesign Directive (2009/125/EC) set clear markers for the future. Although science and industry have known the environmental impacts of separating manufacturing processes for some time, the environmental effects of fusion welding techniques had not been researched before now – despite the fact that they are becoming increasingly important for higher sheet thicknesses, specifically in steel constructions.

As time, material, and energy requirements for joining techniques rise disproportionately with the sheet thicknesses processed, the life-cycle assessment (LCA) of thick metal plate welds is of interest to all market participants.

This study applies the LCA method to manual metal arc welding (MMAW), laser arc-hybrid welding (LAHW), and gas metal arc welding in two variants (GMAW standard and GMAW modified).

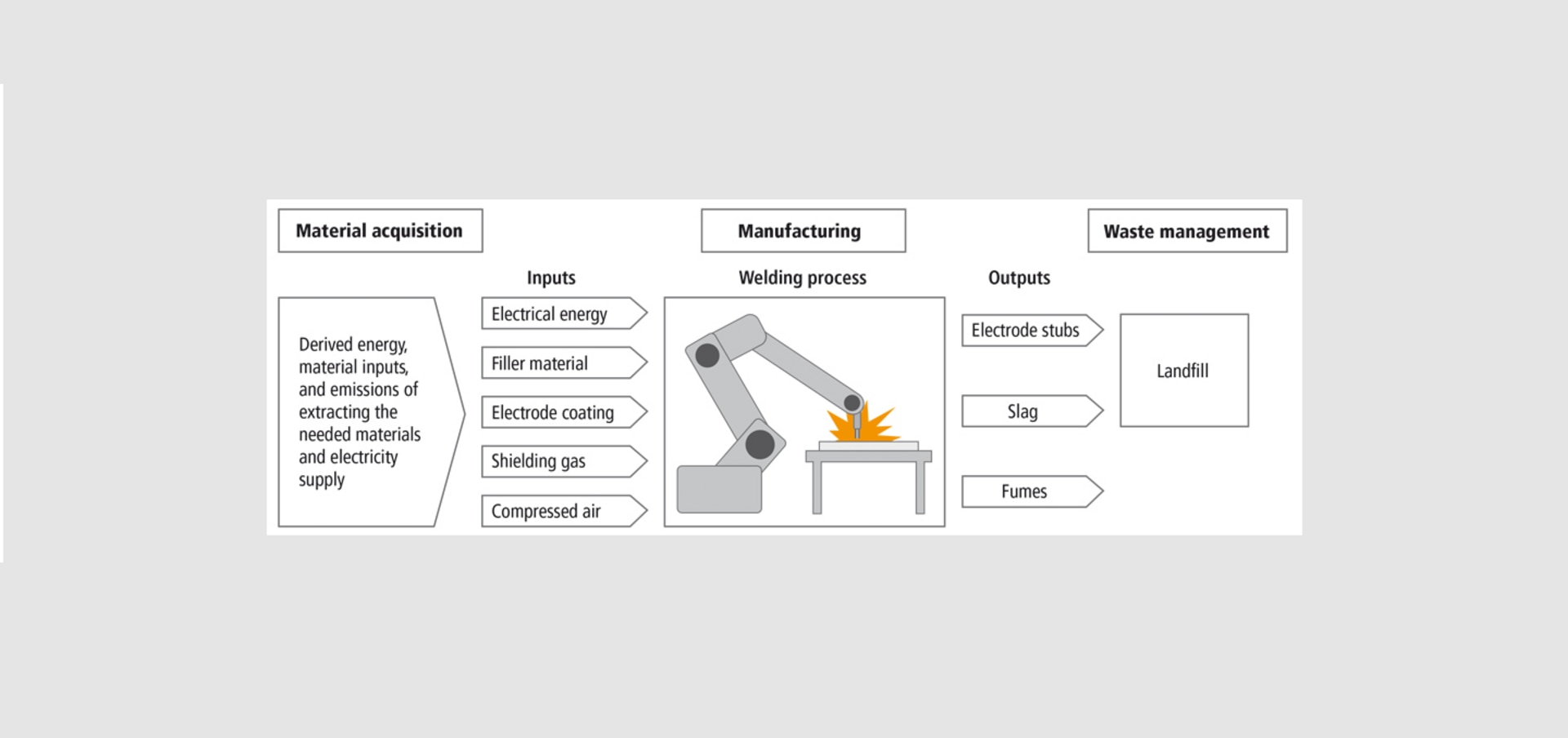

Life-cycle assessment is a widely used and standardized method for assessing the environmental impacts of a product or process. It is described both in the applicable standards and norms and in the specialist literature. An LCA analyzes the life cycle of a product or process from the extraction of raw materials and energy production all the way through to their use. There are four main phases (goal and scope, life cycle inventory, life cycle impact assessment, and interpretation), which are processed iteratively.

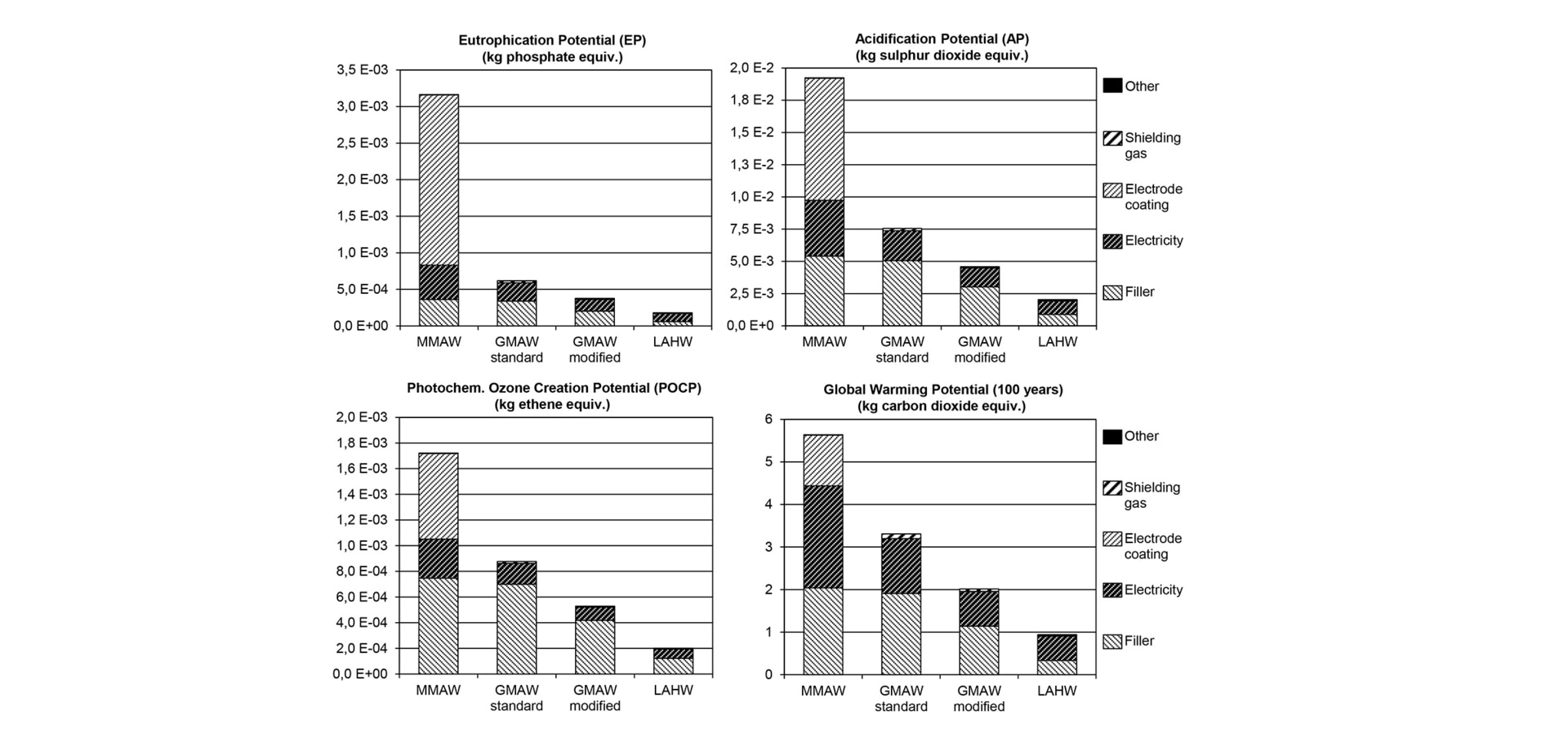

The results show that manual metal arc welding causes by far the highest potential environmental impacts in the categories of global warming, acidification, eutrophication, and photochemical ozone creation. Laser arc-hybrid welding performs the best, followed by gas metal arc welding with a modified spray arc and a reduced groove angle.

Experimental framework

The goal of these LCAs is to evaluate the potential environmental impacts of various welding processes for one meter of weld joint. The object of study is butt joints of low-alloy mild steels with a sheet thickness of 20 mm. Only the process is observed; the required equipment is not taken into account.

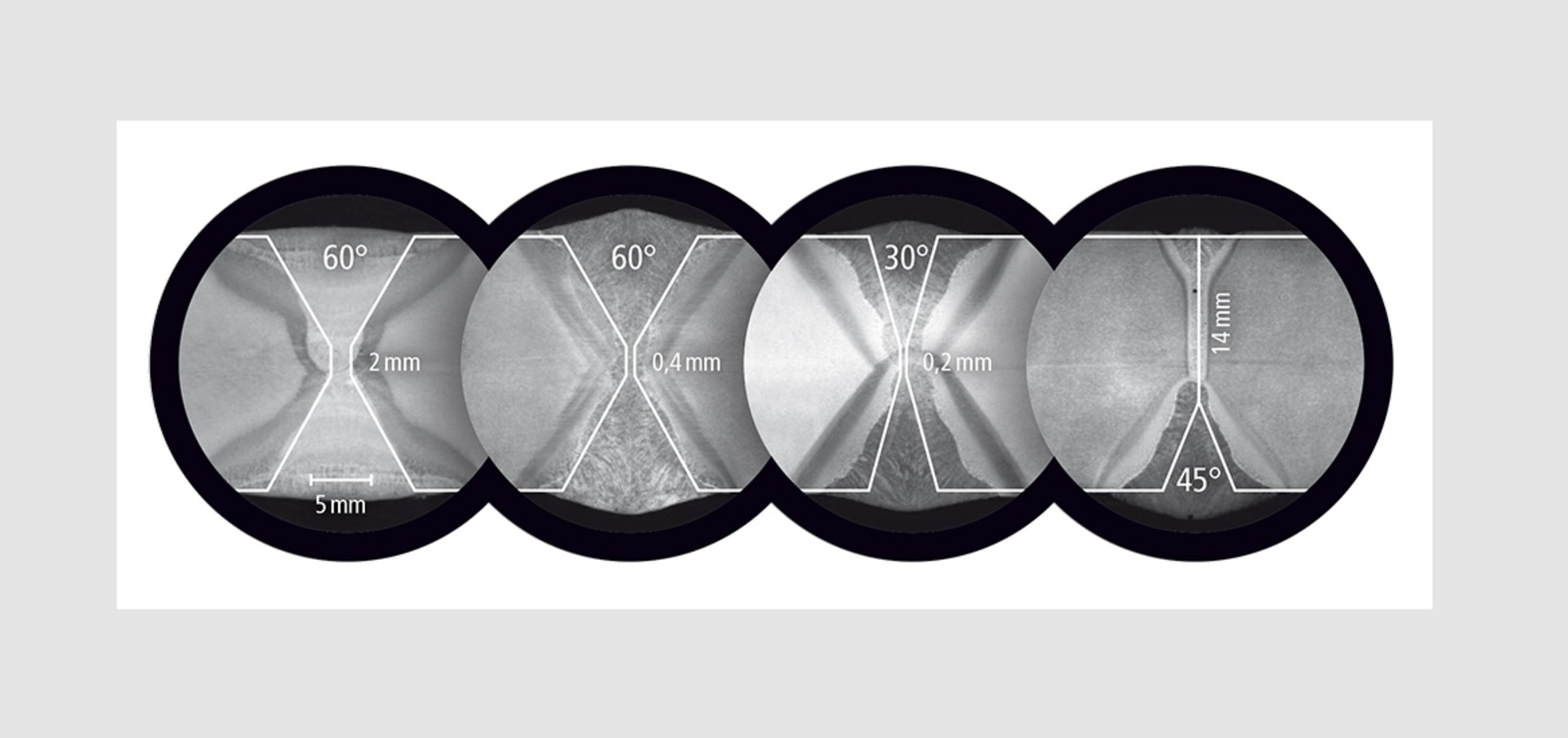

Manual metal arc welding (MMAW) was executed in six passes with a double-V joint preparation (60° groove angle, 2 mm gap, 2 mm face) and a homogeneous thickly rutile-coated electrode. Laser arc-hybrid welding (LAHW) was executed with a Y-groove joint preparation (45° groove angle, 14 mm face) and homogeneous solid wire, whereby the root was carried using LAHW and the finishing pass was carried out using GMAW.

The standard GMAW variant was executed in four passes with a double-V joint preparation (60° groove angle, 0.4 mm gap, 2 mm face). For the modified GMAW variant, a modern modified spray arc was used, which allowed the groove angle to be reduced to 30°.

Inventory results

Figure 2 shows the microsections and joint preparations of the welded sheets, which are characterized by the groove angle, the gap, and the face.

The areas delineated by the joint preparations are qualitative representations of the inventory results. The LAHW technique requires by far the least amount of electrical energy, filler material, and shielding gas. The MMAW method requires the most inputs, followed by the GMAW standard variant. The reduction of the groove angle from GMAW standard to GMAW modified leads to substantial savings.

From inventory to impact assessment

As in the inventory, the LAHW method again achieves the best result in the impact assessment, followed by the two GMAW variants and the MMAW method. Filler material, power consumption (electricity), and rutile coating for MMAW were identified as the dominant inputs.

Shielding gas and the inputs grouped together under the heading “Other” such as slag, compressed air, electrode stubs, and welding fumes have no significant influence on the indicator values. Equally, the energy consumption of the welding robots make only a small contribution to environmental impacts, as they make up less than 10% of the power consumption of the respective methods (excepting MMAW of course, which is manual).

Principal influencing factors

In the EP (eutrophication potential) and AP (acidification potential) impact categories, different inputs are dominant depending on the technique used. For example, rutile coating has the biggest effect on EP and AP in the case of MMAW; the filler material has the biggest effect in the case of GMAW; and power consumption has the biggest effect in the case of LAHW. In the POCP (photochemical ozone creation potential) category, the filler material is the dominant influence for all welding methods.

In the GWP (global warming potential) category, filler material and power consumption are equally significant, whereby the filler material is slightly more important for GMAW and power consumption is slightly more important for LAHW. In summary, a different input is decisive for most of the potential environmental impacts depending on the welding method. The rutile coating of the electrode is the chief cause for MMAW, the filler material is the chief cause for GMAW, and power consumption is the chief cause for LAHW.

LCA

Among the methods studied, LAHW is the most environmentally friendly. The reason for this twofold: the low amount of filler material required and the high welding speed. Despite the low efficiency rate of the beam source (30%) and the need to factor in an external cooler, the high welding speed means that there is a favorable ratio of electricity input to welding time and therefore low power consumption.

In contrast, a lot of material is input in MMAW and, moreover, partly re-fused in multiple passes. On account of the high dominance of the filler material in GMAW, the reduction of the groove angle by using the modified spray arc is particularly effective.

Levers to improve environmental impacts

The way to improve the potential environmental impacts for the respective welding methods can be inferred directly from the dominant inputs. In LAHW, power consumption is dominant, which is determined primarily by the efficiency rate of the beam source.

Consequently, future development work should focus particularly on the efficiency rate. In GMAW, the filler material to be input should always be kept to a minimum. In MMAW, alternative coatings should be researched in order to reduce the potential environmental impacts.

Practical relevance

Despite the clear results, the study’s significance is limited to the defined framework conditions. Accordingly, it should not be used as the sole criterion when choosing a process. The most important restriction was the study’s exclusive focus on the process without taking into account the equipment required (welding devices, robots, beam sources, etc.), which is actually a crucial factor for environmentally-oriented process selection, particularly when planning new production operations.

Furthermore, no technological framework conditions (production tolerances, accessibility, etc.) of application were studied, although they are vitally important when it comes to process selection. And finally, the LCA methodology is limited in its impact assessment to just four major categories, and so no general conclusions may be drawn from them about all impact categories.

Summary

The primary causes of potential environmental damage are the rutile coating of the electrode in the case of MMAW, power consumption in the case of LAHW, and filler material consumption in the case of modified GMAW.

Under the given experimental design, which does not take into account the equipment and the technological boundary conditions, the modern high-performance LAHW and GMAW with modified spray arc can be recommended for the welding of thick metal sheets.

This article was first published in November 2015 in the TRUMPF Magazine Laser Community.