Being connected is a powerful idea. It implies being close to someone and understanding where they’re coming from, but also being loyal and taking their side. In many cases, that feeling of camaraderie, of a common identity, is fostered by sharing experiences or a certain way of life. As the Swiss writer Max Frisch once said: “Words unite us only if we are already on the same wavelength.”

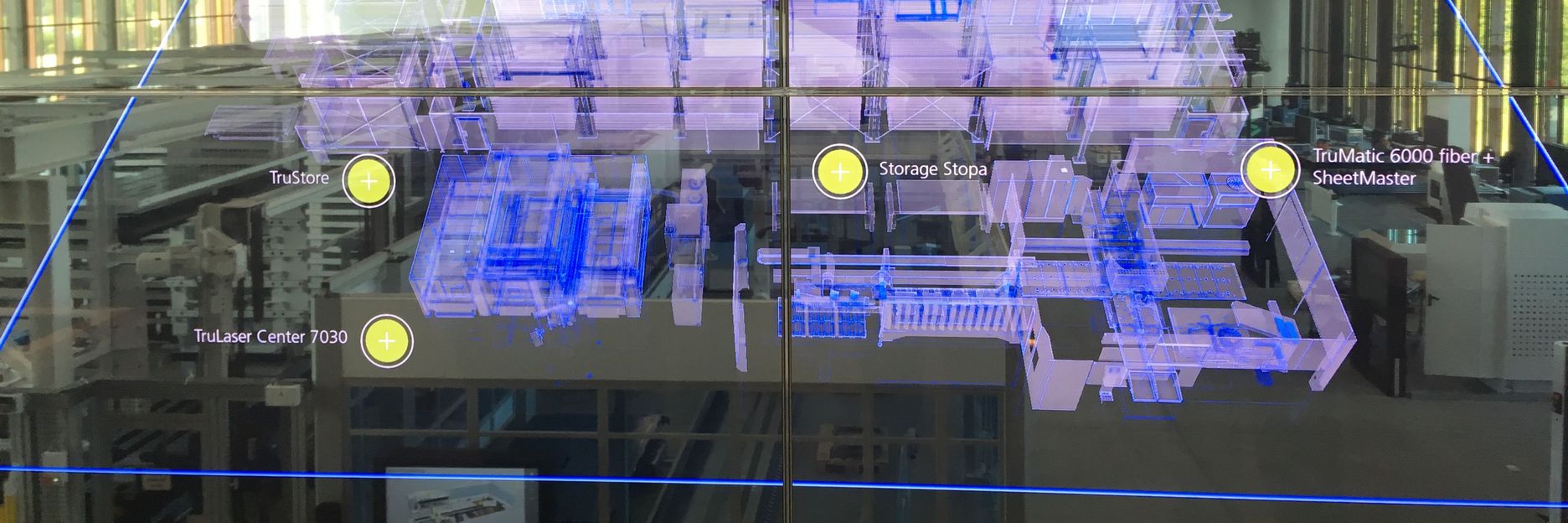

At TRUMPF, we’ve always believed in reaching our customers not just through words, but also through shared experiences and convictions. Back in 1960, we packed our most important machines into a lovingly restored Volkswagen camper van and made the rounds of potential customers. In 1987, we opened our first real showroom at our headquarters in Ditzingen, and since then thousands of customers have passed through its doors. Over the past two decades we have added showrooms all over the world, including the recent unveiling of a fully-fledged Industry 4.0 demonstration factory in Chicago in September. Every last aspect of it is designed to live and breathe Industry 4.0.

And that’s only the beginning.

Digital ambition: For our customers and partners as well as our employees

We are growing even more connected to our customersthrough digital connectivity. We exchange more information nowadays than ever before, and that means we know a lot about each other, which can be mutually beneficial. From TRUMPF’s perspective, it means we can provide the best support and maintenance services for our customers’ machinery – by ensuring that repairs and software updates are implemented on a timely basis, for example. We can also monitor each machine’s performance and give useful tips on how it could be improved. Knowing exactly how a machine is being used allows us to draw up highly personalized offers that include everything from support service packages to finance solutions.

Based on our years of experience, we can provide our customers with solid and authoritative advice when it comes to optimizing business processes and fostering digital connectivity. One example of the solutions we offer is our TruConnect range of software services. Another example is our open, digital business platform AXOOM, which we hope will place us firmly among the ranks of the leading providers of business-process software in the manufacturing industry. That’s our goal.

The products and services we offer enable our customers to produce their goods far more efficiently, with studies suggesting average productivity gains of 30 percent. What’s more, we are responding faster than ever before. We now resolve 75 percent of support incidents remotely, and we can access some 15,000 machines all over the world through our service cloud. We understand that spare parts and consumables are often critical to keeping production running without interruption; they reach our customers quickly thanks to our customer processes 4.0. Every customer has their own personalized service portal to provide the perfect framework for keeping in touch with TRUMPF.

All in all, things run smoother and faster when we facilitate a certain level of transparency on both sides.

Careful Analysis key. Our goal is to eliminate unscheduled downtime.

To ensure both sides make the most of this opportunity, we are making significant investments in our products’ connectivity. We are equipping our machines and lasers with cutting-edge data interfaces and developing new methods of ultra-secure data transmission. At the same time, we are building user-friendly analysis tools that extract useful information from the huge quantities of data our products generate. This includes status updates on a customer’s machinery, upcoming maintenance requirements, imminent shortages of materials, and information on which systems or production units have been working fastest over a defined period of time. All this results in greater transparency.

To avoid unproductive downtime, you need to eliminate the risk of sudden machine stoppages and maintain the right stocks of materials as well as ensure that all systems are working to capacity and can even be operated remotely. By pursuing this approach, we can get closer and closer to the goal of zero unplanned downtime,

substantially reduce throughput times, and ensure a more rigorous adherence to customer deadlines. That makes production processes more predictable and reliable than ever before.

We can apply a similar concept to upstream and downstream processes as well as the actual production process. Everyone benefits when an order is placed online: the part is designed automatically, and the machine works autonomously to convert this information into a machining program and then assign the finished parts to the right order. The whole ordering process becomes faster and more transparent while eliminating the risk of errors. Delivery companies are already capable of tracking parcels with tremendous accuracy right up to the point of delivery, and in the future this degree of control will also be available for sheet metal parts. This will make it commercially viable for companies to deal with growing numbers of customer-specific, small-batch orders. And adding a 3D printer such as TruPrint to the production environment will create an almost unlimited capacity for customization.

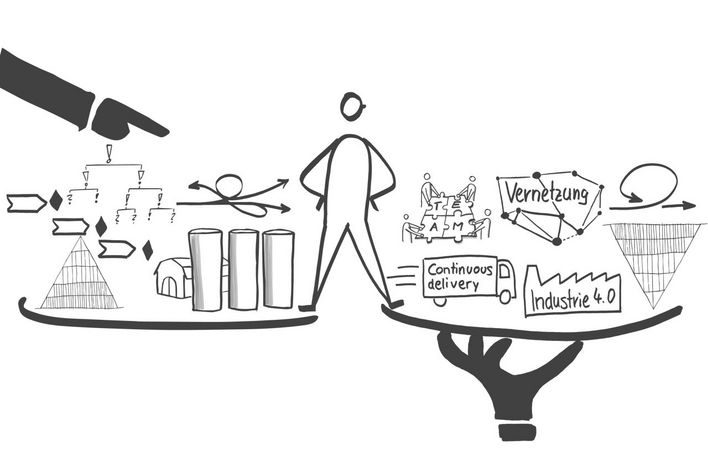

Agile collaboration - mastering complexity

Our entire organization is currently confronting huge challenges due to digital transformation, especially with regard to the pace of development and the courage to embrace change. Our development team is proceeding full speed ahead on a broad range of tasks. These include creating innovations in software, providing access to cloud platforms, implementing disruptive business models – both within and beyond the sheet metal and laser sectors – and creating new machine designs for modern production processes.

Our sales and service staff are equally busy keeping their knowledge primed about all of these offerings while communicating it to customers through new channels. Our corporate HR department is currently focused on recruiting additional people for these tasks and achieving consistent implementation of all our HR processes worldwide. The list of these challenges goes on and on, but one way to tackle them is to implement “agile collaboration 4.0,” an approach that we have already identified as the best way forward in many areas.

The results are clear: encouraging more and more departments to cooperate with each other using new methods and organizational structures produces tremendous efficiency and is enriching for everyone involved. We firmly believe that this interdisciplinary, iterative form of collaboration is the future. And we’re equally confident that digitalization is having a positive effect on TRUMPF employees’ daily lives and reinforcing our reputation as a good employer. Our positive recruitment path starts with the system of dual vocational training programs, which is essentially a form of “didactics 4.0.” Ultimately, of course, it encompasses education in its broadest sense – in other words, the ability to communicate new learning and bring it to life while breaking down people’s reservations and anxieties. By committing to transparency on all sides, we can acquire the kind of digital skills that will reveal new opportunities for development and new career profiles.

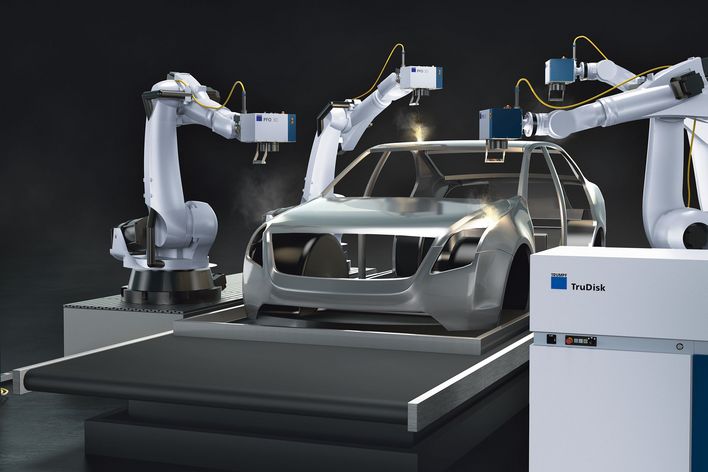

We welcome the future with open arms - with our customers right by our side

The laser is our favorite tool. It leaves us perfectly positioned to face the future because it is the most suitable machining tool for Industry 4.0 production. It is an important enabler for the production of microchips, and a key customization tool that marks workpieces with unique codes containing process and customer information. It is also a creator of parts that yields the maximum possible range of products through cutting, welding, coating, ablating, roughening, polishing, and a multitude of other machining processes. Whatever upheaval and conceptual leaps we face, and whatever unfamiliar territories we may enter in the realms of collaboration and digital opportunities, we can be confident of one thing – we can always rely on our “tool 4.0”.

This is a tool that still has plenty of untapped potential, which is why Peter Leibinger was appointed Chief Technology Officer in July 2017 – placing a major focus on additive manufacturing and opening up new business fields. Meanwhile, Chief Digital Officer Mathias Kammüller – another member of the Group Management team – is now devoting himself to strategic planning and effective implementation of the company’s digital transformation. All this will help ensure that TRUMPF takes the fast track into the future. The fact is that connectedness is inextricably linked to a sense of being able to depend on someone. When you work with TRUMPF, you can rely on us to live up to our reputation as a true promoter of innovation and to seize every available opportunity to benefit our customers.

We're shaping the future of the world. And we're doing that in our own unique style.

There’s one more point we feel is important. You might call it a kind of digital ambition that extends well beyond our company and our industry and that sums up how we do business. We’re determined to use our long-established tradition of collaborating with social partners and educational institutions as a basis for constructing our own unique style of digital transformation. We believe the time has come to state with confidence that Silicon Valley found its own particular path and its own values – and now owner-managed, medium-sized companies such as TRUMPF are stepping up and finding theirs.