Expand the programmable focusing optics from TRUMPF with options for image processing. PFO is able to detect geometries on the surface of the workpiece and adapt the laser process to the individual processing situation.

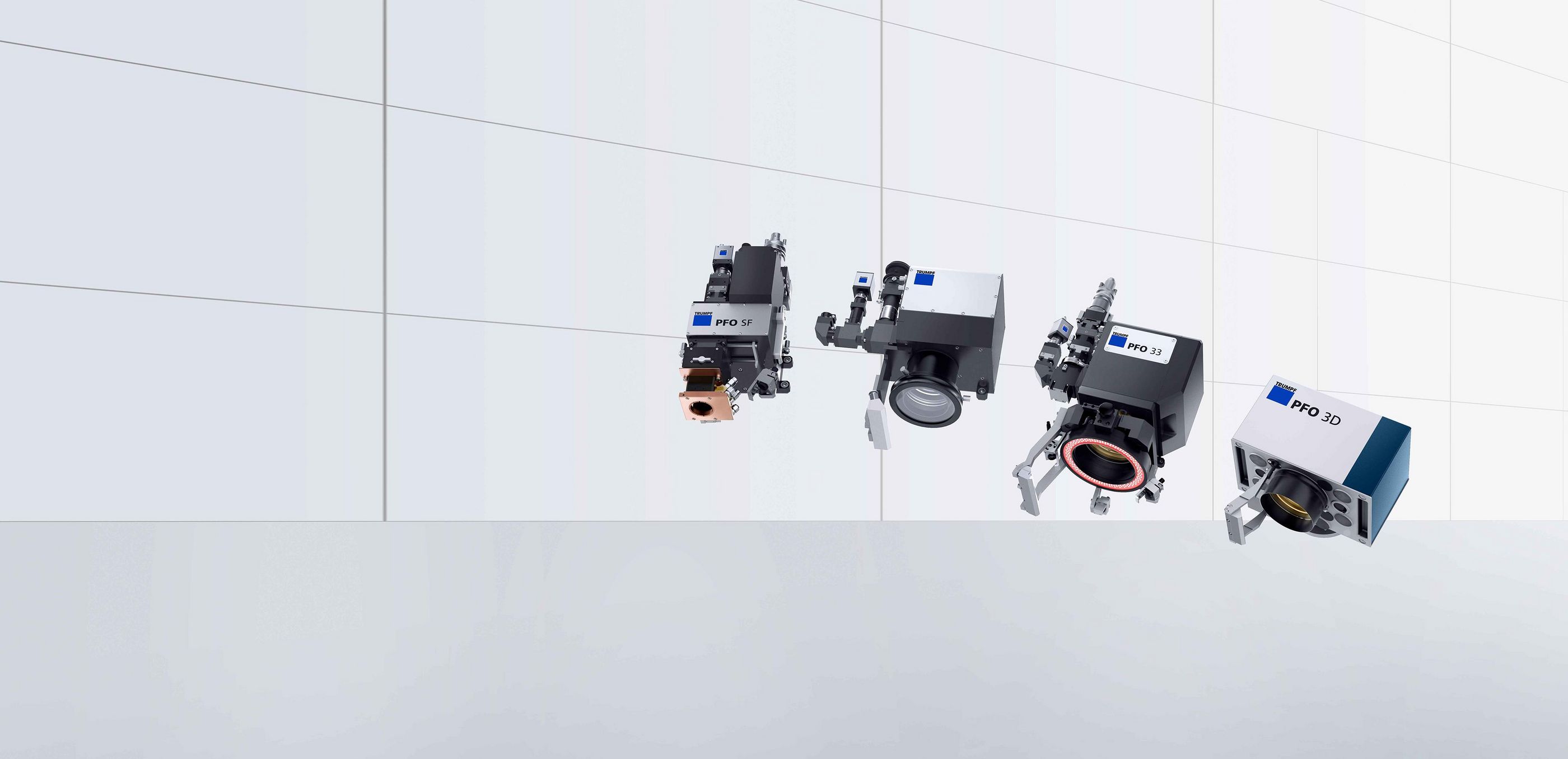

TRUMPF optics for remote processing

The programmable focusing optics from the PFO line are scanner optics for remote welding and cutting. Using two mirrors, the laser beam can be positioned in any specified position within the processing field or space, or be guided along any seam geometries. They can thus be welded without moving the workpiece or the focusing optics. Additionally, no shielding/assist gas is required.

State-of-the-art, digitally controlled drives ensure a fast pace.

Robot, laser, and programmable focusing optics are synchronized and positioned precisely in real time.

In the PFO portfolio you will find a solution for every application, from the low-power to the high-power range.

Increased process reliability and quality are possible with optional intelligent sensor solutions.

Set up laser welding and cutting programs in an intuitive, mobile, and quick way with the PFO SmartTeach app.

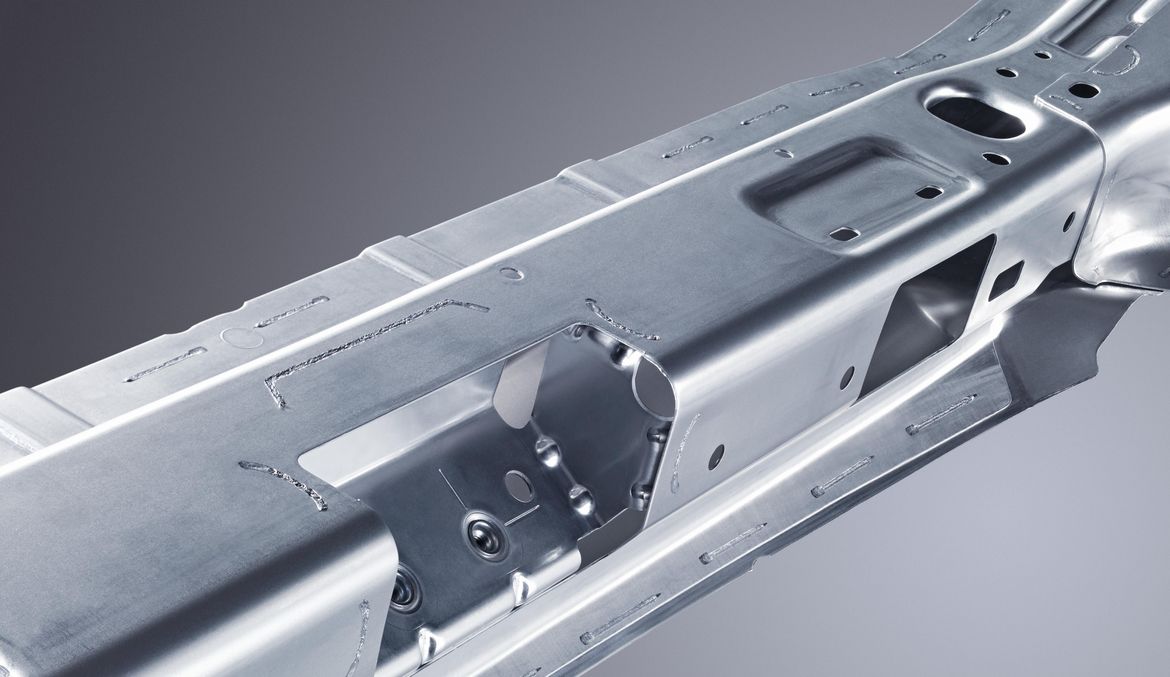

Car door

The programmable focusing optics (PFO) from TRUMPF are especially well-suited for quick and reliable processing of large workpieces. The combination of robots and PFO brings together the best of both worlds: a large work area with excellent dynamics and precision, and a long focal length that enables large working distances from the workpiece.

Scanner welding of a car door

Using two mirrors, the laser beam can be positioned in any specified position within the processing field or space, or guides the laser beam along any desired contours. Since neither the workpiece nor the optics have to move, the PFO enables a high degree of productivity. At the same time, processing costs remain low and process results are reliable. "On the fly" processes can even be achieved using a special control unit.

Rear center panel of an automobile chassis

A high degree of precision and repetition accuracy across a large working range – robot-guided scanner welding results in immense increases in productivity with large workpieces.

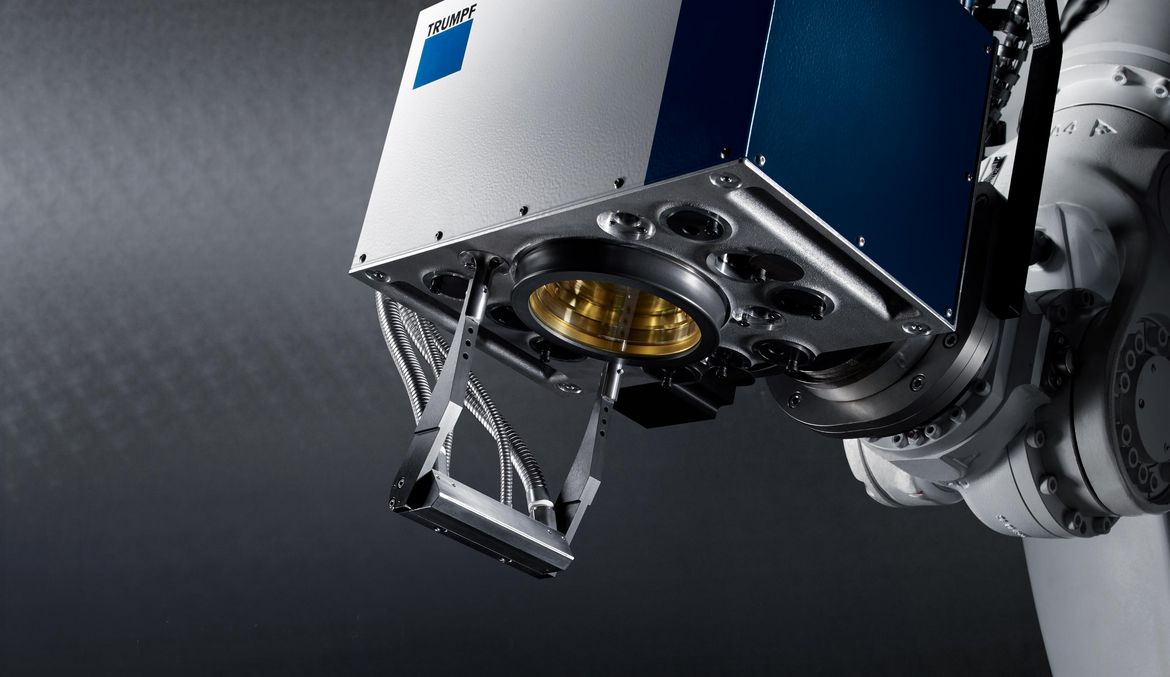

Scanner welding with PFO 3D

The mirrors in the PFO 3D programmable focusing optics work in a highly dynamic manner. Quick beam deflection shortens processing and positioning time considerably.

Lasergeschweißte Kunststoffteile

Mit den programmierbaren Fokussieroptiken von TRUMPF können nicht nur metallische Werkstoffe geschweißt werden, sondern auch Kunststoffe. Die Optik PFO 20 ist optimal für das Laser-Kunststoffschweißen ausgelegt und erzeugt dichte und ästhetische Schweißnähte.

Battery housing

With the programmable focusing optics from TRUMPF, you can weld not only metallic materials, but also plastics. The PFO 20 optics are optimally designed for laser welding plastic and produce tight and aesthetically pleasing weld seams.

|

PFO 14

Compare product

|

PFO 20

Compare product

|

PFO 33

Compare product

|

PFO 1D

Compare product

|

PFO 3D

Compare product

|

PFO SF

Compare product

|

|

|---|---|---|---|---|---|---|

| Laser parameters | ||||||

| Wavelength | - | - | - | - | - | - |

| Power | up to 2000 W (cw) | up to 2000 W (cw) | up to 12000 W (cw) | up to 8000 W (cw) | up to 8000 W (cw) |

PFO SF20: to 8000 W (cw)

PFO SF33: to 12000 W (cw) |

| Numerical aperture | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 |

| Laser light cable type | LLK-D, LLK-B, LLK-A | LLK-D, LLK-B, LLK-A | LLK-D | LLK-D, LLK-B | LLK-D | LLK-D |

| Optics configuration 1 | ||||||

| Collimation | 35 / 56 mm | 35 / 56 / 80 / 90 / 100 mm |

140 mm (TruDisk & TruFiber Multiple Mode)

150 / 200 / 300 mm (TruFiber Single Mode) |

150 mm | 138 mm |

PFO SF20: 90 mm (TruDisk, TruMicro 7000, TruFiber Multi Mode)

PFO SF20: 150 / 200 mm (TruFiber Single Mode) PFO SF33: 140 mm (TruDisk, TruMicro 7000, TruFiber Multi Mode) |

| Focal length | 100 / 160 / 163 / 254 / 330 / 420 mm | 90 / 100 / 135 / 160 / 163 / 200 / 254 / 264 / 280 / 330 / 395 / 420 / 560 / 740 mm |

255 / 345 / 450 mm (Standard)

160 / 265 / 345 / 450 / 600 mm (HighBrightness) |

150 / 200 / 300 mm | 255 / 345 / 450 / 600 / 900 mm | 200 / 300 / 400 / 500 / 600 mm |

| Z stroke for focal length of lens | - | - | - | - |

f345: ± 40 mm

f450: ± 70 mm f600: ± 100 mm f900: ± 220 mm |

- |

| Field size (ellipse Y x X) for focal length of lens |

f100: 47 mm x 18 mm

f160: 110 mm x 75 mm f163: 110 mm x 70 mm f254: 170 mm x 120 mm f330: 220 mm x 178 mm f420: 286 mm x 230 mm |

f100: 50 mm x 36 mm

f135: 70 mm x 50 mm f160: 86 mm x 66 mm f264: 180 mm x 136 mm |

- | - |

f255: 174 mm x 102 mm (z=0)

f345: 240 mm x 140 mm (z=0) f450: 320 mm x 190 mm (z=0) f900: 525 mm x 340 mm (z=0) |

f200: 11 mm x 17 mm

f300: 17 mm x 25 mm f400: 22 mm x 34 mm f500: 28 mm x 42 mm f600: 28 mm x 42 mm |

| Field size (ellipse Y x X) for focal length of lens for TruDisk/TruMicro | - | - |

f255: 180 mm x 112 mm

f345: 244 mm x 150 mm f450: 320 mm x 196 mm |

- | - | - |

| Field size (ellipse Y x X) for focal length of lens for HighBrightness lenses | - | - |

f160: 80 mm x 57 mm

f265: 140 mm x 102 mm f345: 208 mm x 152 mm f450: 306 mm x 208 mm f600: 388 mm x 257 mm |

- | - | - |

| Field size (ellipse Y x X) for focal length of lens for TruFiber | - | - |

f265: 140 mm x 102 mm

f345: 208 mm x 152 mm f450: 306 mm x 208 mm f600: 388 mm x 257 mm |

- | - | - |

| Field size (ellipse Y x X) for focal length of lens for TruDisk 515 Nm | - | - |

f160: 77 mm x 56 mm

f265: 140 mm x 102 mm f345: 202 mm x 144 mm f450: 312 mm x 190 mm |

- | - | - |

| Structural design | ||||||

| Dimensions (W x H x D) | 278 mm x 391 mm x 202 mm (configuration example with fc56 and f160) | 278 mm x 296 mm x 202 mm (configuration example with fc90 and f264) | 336 mm x 340 mm x 227 mm (configuration example with fc140 and f450) | 227 mm x 562 mm x 229 mm | 412 mm x 266 mm x 366 mm |

223 mm x 200 mm x 198 mm (Scanner head without objective lens)

120 mm x 195 mm x 252 mm (PFO control unit) |

| Weight | 15 kg | 15 kg |

< 35 kg

< 38 kg with OCT scanner |

12.5 kg | 35 kg |

13 kg (Scanner head)

4 kg (PFO control unit) |

| Compatibility | ||||||

| Available lasers | TruDiode, TruDisk, TruMicro | TruDiode, TruDisk, TruFiber, TruMicro, TruPulse | TruDisk, TruFiber, TruMicro | TruDiode, TruDisk | TruDisk |

PFO SF 20: TruDisk, TruMicro 7000, TruFiber multiple mode, TruFiber single mode

PFO SF 33: TruDisk, TruMicro 7000, TruFiber multiple mode |

| Available sensor system | - | VisionLine, CalibrationLine, temperature control for plastic welding and curing | VisionLine Cam/Basic/Detect, VisionLine OCT Detect, CalibrationLine | - | VisionLine, CalibrationLine, SeamLine Remote, OCT seam position control | VisionLine Cam/Basic/Detect, CalibrationLine |

| Options | ||||||

| Available options | Crossjet, camera monitoring | Crossjet, sensor interface, lighting | Crossjet, MVE nozzle, smoke bell, camera monitoring, sensor interface, lighting, protective glass monitoring unit | Crossjet, MVE nozzle, shielding gas supply, camera monitoring, sensor interface, lighting, cartridge module, protective glass monitoring unit | I-PFO, crossjet, MVE nozzle, smoke bell, lighting version | Crossjet, MDE nozzle, various inert gas nozzles, camera monitoring, sensor interface, lighting, safety glass monitor, coolant monitor |

| Available software options | TruTops PFO, PFO Smart Teach App | TruTops PFO, PFO Smart Teach App | TruTops PFO, PFO Smart Teach App, Real-time contour check | - | TruTops I-PFO and TruTops PFO, PFO Smart Teach App | TruTops PFO, PFO Smart Teach App, Real-time contour check |

|

PFO 14

|

PFO 20

|

PFO 33

|

PFO 1D

|

PFO 3D

|

PFO SF

|

|

|---|---|---|---|---|---|---|

| Laser parameters | ||||||

| Wavelength | - | - | - | - | - | - |

| Power | up to 2000 W (cw) | up to 2000 W (cw) | up to 12000 W (cw) | up to 8000 W (cw) | up to 8000 W (cw) |

PFO SF20: to 8000 W (cw)

PFO SF33: to 12000 W (cw) |

| Numerical aperture | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 |

| Laser light cable type | LLK-D, LLK-B, LLK-A | LLK-D, LLK-B, LLK-A | LLK-D | LLK-D, LLK-B | LLK-D | LLK-D |

| Optics configuration 1 | ||||||

| Collimation | 35 / 56 mm | 35 / 56 / 80 / 90 / 100 mm |

140 mm (TruDisk & TruFiber Multiple Mode)

150 / 200 / 300 mm (TruFiber Single Mode) |

150 mm | 138 mm |

PFO SF20: 90 mm (TruDisk, TruMicro 7000, TruFiber Multi Mode)

PFO SF20: 150 / 200 mm (TruFiber Single Mode) PFO SF33: 140 mm (TruDisk, TruMicro 7000, TruFiber Multi Mode) |

| Focal length | 100 / 160 / 163 / 254 / 330 / 420 mm | 90 / 100 / 135 / 160 / 163 / 200 / 254 / 264 / 280 / 330 / 395 / 420 / 560 / 740 mm |

255 / 345 / 450 mm (Standard)

160 / 265 / 345 / 450 / 600 mm (HighBrightness) |

150 / 200 / 300 mm | 255 / 345 / 450 / 600 / 900 mm | 200 / 300 / 400 / 500 / 600 mm |

| Z stroke for focal length of lens | - | - | - | - |

f345: ± 40 mm

f450: ± 70 mm f600: ± 100 mm f900: ± 220 mm |

- |

| Field size (ellipse Y x X) for focal length of lens |

f100: 47 mm x 18 mm

f160: 110 mm x 75 mm f163: 110 mm x 70 mm f254: 170 mm x 120 mm f330: 220 mm x 178 mm f420: 286 mm x 230 mm |

f100: 50 mm x 36 mm

f135: 70 mm x 50 mm f160: 86 mm x 66 mm f264: 180 mm x 136 mm |

- | - |

f255: 174 mm x 102 mm (z=0)

f345: 240 mm x 140 mm (z=0) f450: 320 mm x 190 mm (z=0) f900: 525 mm x 340 mm (z=0) |

f200: 11 mm x 17 mm

f300: 17 mm x 25 mm f400: 22 mm x 34 mm f500: 28 mm x 42 mm f600: 28 mm x 42 mm |

| Field size (ellipse Y x X) for focal length of lens for TruDisk/TruMicro | - | - |

f255: 180 mm x 112 mm

f345: 244 mm x 150 mm f450: 320 mm x 196 mm |

- | - | - |

| Field size (ellipse Y x X) for focal length of lens for HighBrightness lenses | - | - |

f160: 80 mm x 57 mm

f265: 140 mm x 102 mm f345: 208 mm x 152 mm f450: 306 mm x 208 mm f600: 388 mm x 257 mm |

- | - | - |

| Field size (ellipse Y x X) for focal length of lens for TruFiber | - | - |

f265: 140 mm x 102 mm

f345: 208 mm x 152 mm f450: 306 mm x 208 mm f600: 388 mm x 257 mm |

- | - | - |

| Field size (ellipse Y x X) for focal length of lens for TruDisk 515 Nm | - | - |

f160: 77 mm x 56 mm

f265: 140 mm x 102 mm f345: 202 mm x 144 mm f450: 312 mm x 190 mm |

- | - | - |

| Structural design | ||||||

| Dimensions (W x H x D) | 278 mm x 391 mm x 202 mm (configuration example with fc56 and f160) | 278 mm x 296 mm x 202 mm (configuration example with fc90 and f264) | 336 mm x 340 mm x 227 mm (configuration example with fc140 and f450) | 227 mm x 562 mm x 229 mm | 412 mm x 266 mm x 366 mm |

223 mm x 200 mm x 198 mm (Scanner head without objective lens)

120 mm x 195 mm x 252 mm (PFO control unit) |

| Weight | 15 kg | 15 kg |

< 35 kg

< 38 kg with OCT scanner |

12.5 kg | 35 kg |

13 kg (Scanner head)

4 kg (PFO control unit) |

| Compatibility | ||||||

| Available lasers | TruDiode, TruDisk, TruMicro | TruDiode, TruDisk, TruFiber, TruMicro, TruPulse | TruDisk, TruFiber, TruMicro | TruDiode, TruDisk | TruDisk |

PFO SF 20: TruDisk, TruMicro 7000, TruFiber multiple mode, TruFiber single mode

PFO SF 33: TruDisk, TruMicro 7000, TruFiber multiple mode |

| Available sensor system | - | VisionLine, CalibrationLine, temperature control for plastic welding and curing | VisionLine Cam/Basic/Detect, VisionLine OCT Detect, CalibrationLine | - | VisionLine, CalibrationLine, SeamLine Remote, OCT seam position control | VisionLine Cam/Basic/Detect, CalibrationLine |

| Options | ||||||

| Available options | Crossjet, camera monitoring | Crossjet, sensor interface, lighting | Crossjet, MVE nozzle, smoke bell, camera monitoring, sensor interface, lighting, protective glass monitoring unit | Crossjet, MVE nozzle, shielding gas supply, camera monitoring, sensor interface, lighting, cartridge module, protective glass monitoring unit | I-PFO, crossjet, MVE nozzle, smoke bell, lighting version | Crossjet, MDE nozzle, various inert gas nozzles, camera monitoring, sensor interface, lighting, safety glass monitor, coolant monitor |

| Available software options | TruTops PFO, PFO Smart Teach App | TruTops PFO, PFO Smart Teach App | TruTops PFO, PFO Smart Teach App, Real-time contour check | - | TruTops I-PFO and TruTops PFO, PFO Smart Teach App | TruTops PFO, PFO Smart Teach App, Real-time contour check |

The technical data of all product versions as a download.

PFO 1D

The PFO 1D programmable focusing optics combine the best of both worlds: the robustness of industry-proven TRUMPF fixed optics and the scanner functionality of programmable focusing optics (PFO). The individually adjustable 1D wobbling movement of the laser beam means you benefit from utmost weld seam quality, both during heat conduction welding as well as during deep welding applications.

Laser: TruDisk

Max. laser power: 8 kW (cw)

PFO 14 / PFO 20-2

The PFO 14 and PFO 20-2 programmable focusing optics are ideally suited for spot welding or path welding where high speeds are required. The 2D scanners function according to the pre-objective scanning principle. This allows them to reach all points in the scanner's processing space with high dynamics and consistent beam quality, at a near-constant working distance. You also benefit from easy focusing lens replacement, due to the fact that calibration data is saved in a storage device on the focusing lens. You can easily join complex components with multiple weld seams.

Lasers: TruDisk, TruDiode, TruFiber, TruMicro

Max. laser power: 300 W (TruDiode), 2000 W (TruDisk, TruFiber, TruMicro)

PFO 33

The third generation of the PFO 33 stands for maximum productivity and can be used for applications with a laser power of up to 12 kW. The lightweight mirrors and the new drive architecture enable maximum dynamics. In addition, optimized mechanical and optical assemblies improve the robustness of the optics against back-reflections. Options such as protective glass monitoring and Condition Monitoring help to maximize the availability of your production.

Lasers: TruDisk, TruFiber, TruMicro

Max. laser power: 12 kW (cw)

PFO 3D-2

The PFO 3D-2 programmable focusing optics constitute a 3D scanner which is also based on the pre-objective scanning principle. This allows all points in the scanner's processing space to be reached with high dynamics and consistent beam quality, at a variable working distance. All NC programs are saved locally in the PFO, which also allows for operation without a PC. Optionally, the 3D scanner is also available with TRUMPF TruTops I-PFO offline simulation software, seam tracking with SeamLine Remote triangulation, and the CalibrationLine calibration tool.

Laser: TruDisk

Max. laser power: 8 kW (cw)

I-PFO

The perfect software solution for laser welding when dealing with complex challenges. The TruTops I-PFO software makes it easier to set up and adjust complex tasks that need to be carried out with industrial robots and PFO 3D welding optics.

PFO SF

The PFO SF small-field scanner is the compact and versatile scanner with a small work area for quick beam oscillation.

By selecting the right options (objective, collimator and sensor system), the small-field scanner can be flexibly adapted to your application. The PFO SF is suitable for a power range of up to 12 kW. It is not only powerful but also smart with functions such as the protective glass monitoring unit. The optics can also be integrated across the entire TRUMPF range of solutions.

Lasers: TruDisk, TruFiber, TruMicro

Max. laser power: 12 kW (cw)

TruTops PFO

TruTops PFO is offline software for 2D and 3D programming of your PFO. You can define any paths, edges, or planes of objects created in the CAD editor or loaded from external sources as weld seams. You can simultaneously take into account clamping fixtures in order to optimize the welding sequence and therefore the processing time. The software makes it possible for you to program different wobble methods. You can use the network to connect TruTops PFO with TruControl.

TruTops I-PFO

To make the most of the advantages of intelligent remote processing, you can program the I-PFO with TruTops I-PFO. The offline 3D development tool determines the ideal process and optimizes the path and speed. You can simultaneously take clamping fixtures into account in order to optimize the path of the robot, the welding sequence, and therefore the processing time. The software also analyzes the cycle time and presents it virtually.

PFO SmartTeach

PFO SmartTeach is an application for your programmable focusing optics in the PFO series. It makes creating and setting up laser welding and cutting programs easier. The camera installed on the C-mount of the optics transmits the live image to the app. This enables convenient teaching directly at the component. If you want to create and teach in PFO geometries, you can do this by way of intuitive gesture operation on a tablet PC.

In addition to a range of processing optics, TRUMPF also offers you the right machines and beam sources. This allows you to find exactly the right combination for your application and requirements – all from a single source. When it comes to beam sources, TRUMPF offers all the relevant lasers for the industry. You can rely on our experts, trust us to always have the best solution in mind for your production tasks, and know that we will advise you independently of any preferred technologies.

Expand the PFO programmable focusing optics with a variety of innovative functions.

Various cameras can be directly adapted to the PFO. A digital color camera system enables the sharp detection of contours and edges, for instance. The software of the PFO supports camera operation by way of touchscreen, crosshairs that can be set digitally, and the saving of images. Even in low light, the coaxial and therefore direction-independent lighting brings everything into perspective.

The intelligent PFO (I-PFO) recognizes its own position in the work area of robot, and the position and orientation of the processing points. Based on information on the current robot movement, the I-PFO independently starts processing as soon as it is possible in terms of geometry and process technology. Remote processing "on-the-fly" is thereby possible, which greatly reduces both the positioning time of the robot and the cycle times in your production operations.

PFO SmartTeach is an application for your programmable focusing optics in the PFO series. It makes creating and setting up laser welding and cutting programs easier. The camera installed on the C-mount of the optics transmits the live image to the app. This enables convenient teaching directly at the component. If you want to create and teach in PFO geometries, you can do this by way of intuitive gesture operation on a tablet PC.

Crossjet is a compressed air flow that runs orthogonally to the laser beam. It diverts contamination and spatter and thereby extends the service life of the protective glass. The laser process becomes more robust.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

Footnotes-

Other optics configurations are available on request.

-

Other wavelengths are available on request.