"The best ventilation is one that nobody notices," explains Daniel Morávek, Managing Director of the Czech specialist for ventilation systems and heat recovery technology, Atrea. And he knows what he's talking about: Atrea built the ventilation system for the Czech Republic's tallest residential building, the V Tower in Prague. Romania's first luxury passive house settlement, Amber Gardens, uses heating and ventilation systems from the Czech Republic. And soon, Vienna's tallest residential building, the Danube Flats will use the same systems. Atrea fans are spinning in hospitals, schools, and cinemas. One prestigious project for Atrea is the Škoda factory kitchen, the largest kitchen in the Czech Republic and one of the largest in Europe, where employees prepare over 30,000 meals daily in an area of approximately 1,000 square meters. It even has its own dedicated "dumpling room".

From manual labour to high-tech production

"Commercial kitchens generate heat, odors and steam. We ensure that air is exchanged every minute. At the same time, we prevent drafts so that employees don’t freeze," explains Daniel Morávek. His company develops complete systems to meet these requirements. All Škoda's chefs see on the ceiling are LED panels and lots of ventilation slots. Behind the ceiling are thick hoses, aerosol separators, filters and two large heat recovery systems. Atrea's software controls and manages the ventilation functions – cloud-based and from anywhere in the world. Atrea's systems fit into any type of building, which is precisely what makes production complex. "Many parts of our systems are similar, but nevertheless different," explains Technical Director, Marcel Jenček. Previously for Atrea, it was safest if machinists manually controlled production, changed parts and calibrated equipment for new parts. But Daniel Morávek wanted to increase the effectiveness of his production. A few years ago, the company invested in automation by TRUMPF. This gave production a literal breath of fresh air.

Atrea has trusted TRUMPF for more than 20 years when selecting its machines. The company purchased its first bending machine back in 2000, shortly after it began exporting ventilation systems to Germany. "That was a big boost for the quality of our solutions," explains Daniel Morávek. The challenge lay in setting up a production process that functions like batch production despite the high individual requirements for Atrea's products. "We wanted a fully automated production process with as few employees as possible operating the machines. And that’s why it also needs to be connected to a warehouse system, so that the material flow runs optimally," explains Daniel Morávek. He is the second generation to run the family business. His father Petr founded Atrea in 1990 in the family washroom – shortly after the Velvet Revolution, the end of Czechoslovakia.

Previously, Petr Morávek worked in a large state-owned company. It was the era of cheap nuclear energy. To ventilate a hall, it was sufficient to open the doors – even in winter at minus 20 degrees Celsius. Radiant heaters warmed the incoming air, while fans ensured air exchange. As a first step, his father insulated the hall. He recognized the high energy loss due to this kind of ventilation. This led to the concept for the first heat recovery system. The principle is simple: each system has two fans, one for the supply air and one for the exhaust air. The warm air from inside simultaneously heats the cold outside air that comes in. "Our modern systems still operate on a similar principle, only they are much more efficient," says Daniel Morávek. And much more complex. Nevertheless, skepticism was widespread at the time. "Back then, nobody thought that it was a good idea," his son explains.

Family home transformed into a test project

After the political upheaval, Petr Morávek persevered and spent two years tinkering with the future of his concept in his family home. From this, technology for use in passive houses and low-energy houses was developed. However, the beginnings were marked by great uncertainty for the family. While the father was building the new company, the mother, Tat'ána Morávková, continued working at another company for the time being. After two years, she too joined the family business.

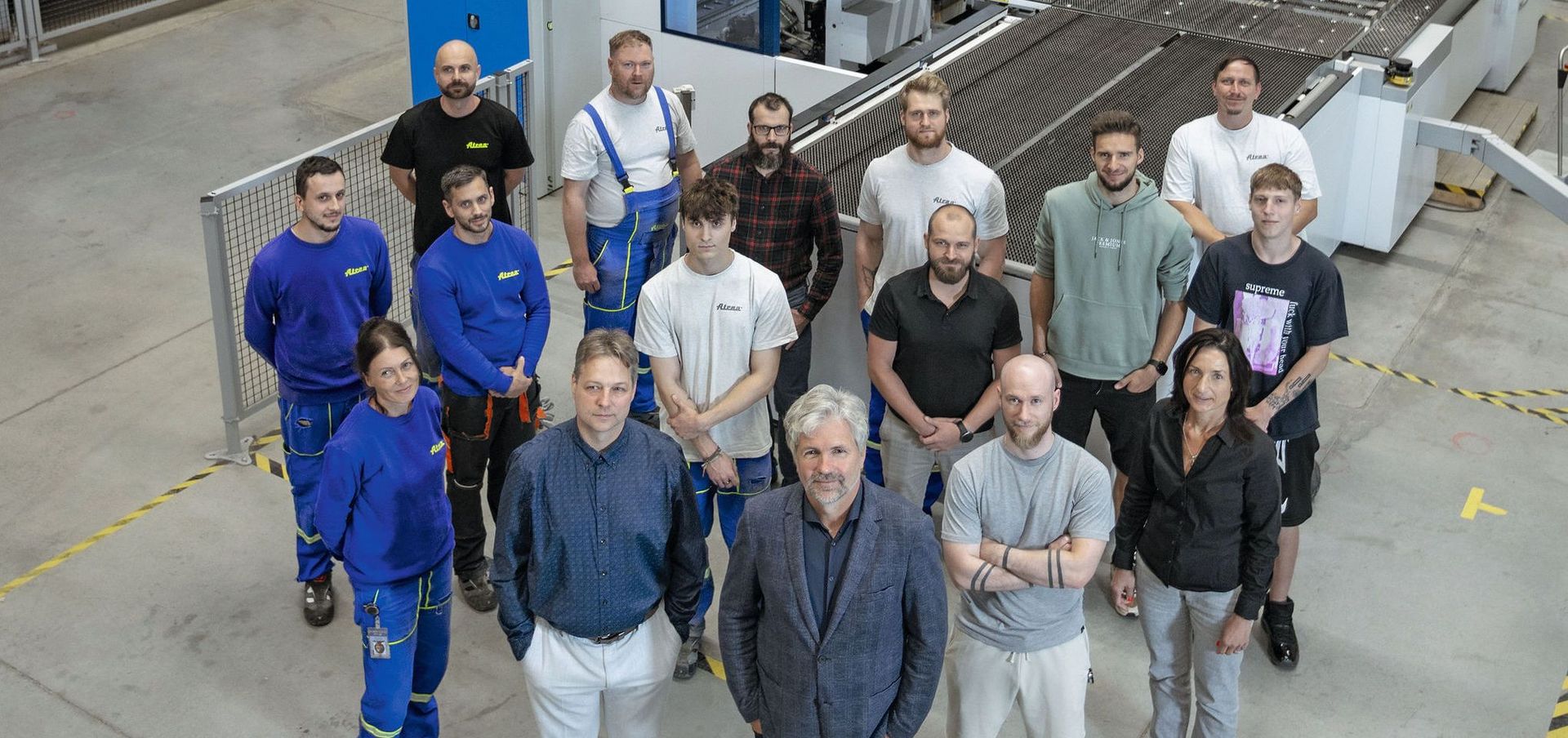

Atrea's current production facility is located in Gablonz an der Neiße, in northern Czechia – 40 kilometers from the Škoda plant, 80 kilometers from Prague and 20 kilometers from the German border. In 2014, the family built the 20,000-sqm production hall according to their own specifications. The solutions needed to be sustainable not only for their customers, but also for Atrea itself. To reduce energy and maintenance costs, the company relies on TRUMPF machines with servo motors. The special thing? The motor only runs during processing. Otherwise, the hydraulics remain at a standstill. "The machines are more compact, consume less energy and maintenance is cleaner", explains Morávek. In 2019, Atrea invested in new machines, the Oseon production software and an integrated STOPA storage system. Today, the TruPunch 5000 punching machine and the TruLaser laser cutting machine 3030 fiber run fully automatically. Employees only launch the program they require. The material flow through the STOPA warehouse is constant. Initial discussions on this began in 2016. "Now, the machines allow us to manufacture flexibly. Oseon has an overview of which parts are produced, no matter how similar they are. The STOPA warehouse independently exchanges materials and returns finished parts to the warehouse," says Daniel Morávek.

Atrea used to produce around 100 parts per hour; now it produces roughly five to six times as many: 85,000 to 100,000 parts per month. To achieve this, the company's five CNC programmers need to create programs for around 600 to 800 different components every day. Prior to automation by TRUMPF, Atrea purchased 70 percent of the parts for its products: "Today we build 100 percent of the systems in-house," explains Technical Director, Marcel Jenček. Employees take on completely different tasks compared with the physically demanding work on the machines. Atrea remains safe and able to grow. In 2024, Atrea integrated the Czech heat pump manufacturer Master Therm into the family holding company. Atrea also has the capacity for large parts of its production.

Looking to the future: research, development and expansion

However, Daniel Morávek does not intend to sit back and relax. Competition in the industry is fierce. A dedicated testing laboratory, the Airlab, is constantly researching the latest trends. "Developing new products and increasing productivity are crucial for us to remain competitive," he explains. Atrea plans to continue growing and has plans to expand and building permits in hand. Morávek plans to double its production area. The Covid-19 pandemic raised awareness of the importance of fresh, clean indoor air. This gives him confidence in the future of the company, after all: "Wherever people live and work, fresh air is needed."