Solutions

EKPO was looking for a laser welding solution that was precise, fast and reliable. "It was clear to us that we needed a laser that not only works extremely precisely, but can also do so reliably under industrial conditions – and the TruFiber can do that," says Bayer. EKPO was particularly impressed by the combination of outstanding beam quality and high process reliability. "There is a lot of know-how in bipolar plates. At the same time, they are also pure mass products, because we need up to 400 of them per fuel cell. And we have weld seams of up to three meters per panel." EKPO produces around 10,000 stacks a year. The fiber laser at the Dettingen site therefore has to draw around 12,000 kilometers of weld seams every year - a boat trip from Hamburg to New York and back again.

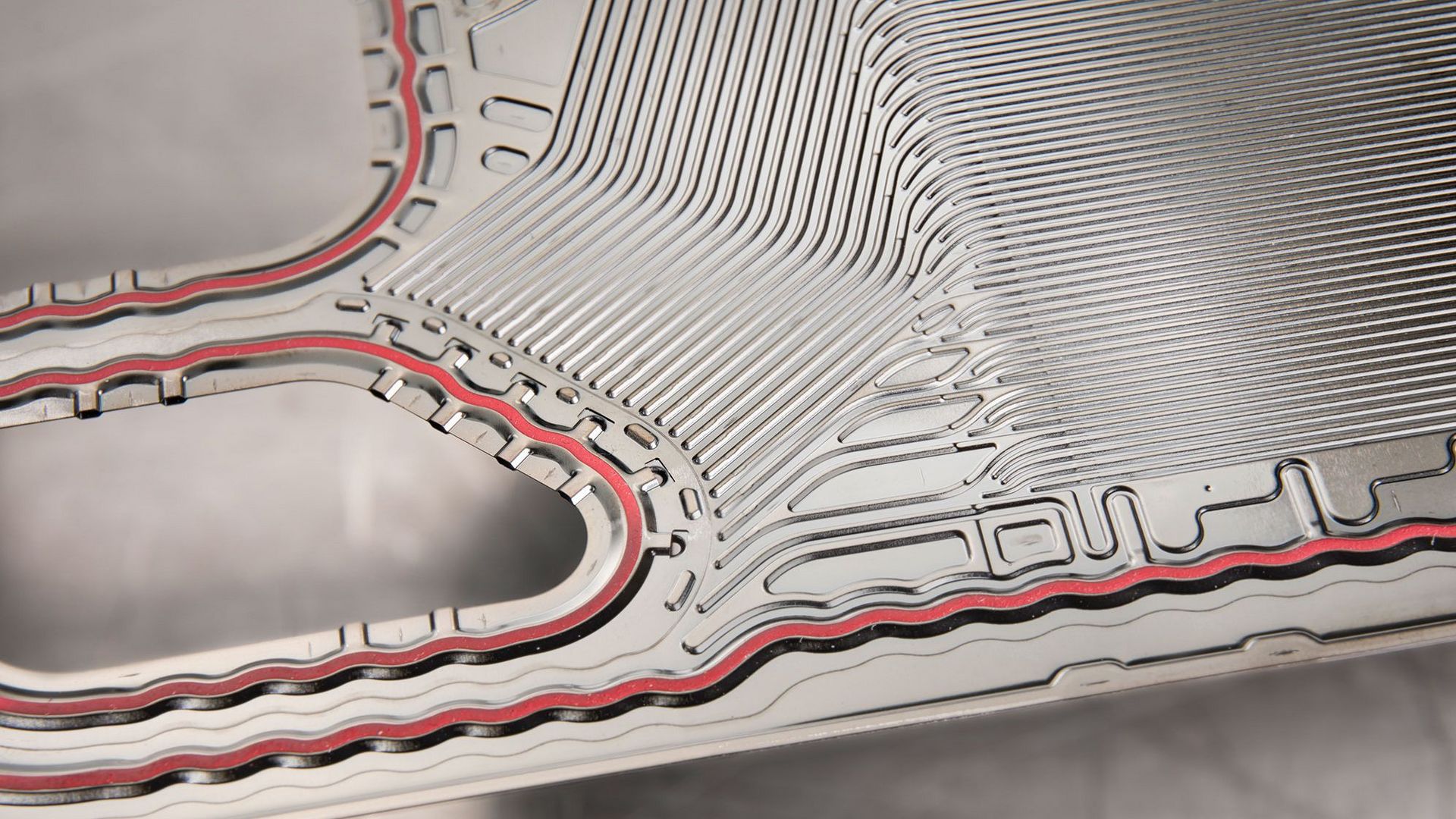

Implementation

In EKPO's automated production line, the laser beam joins the two sides of the bipolar plate to form a gas-tight unit – with weld seams no wider than 0.2 millimeters. In doing so, EKPO moves close to the so-called humping speed limit, at which, for physical reasons, unwanted, bead-like protruding parts appear in the seam. No problem for the fiber laser. It delivers consistently high-quality results, so that the reject rate is well below one percent. The welding process is followed by a demanding conductivity and leak test at up to two bar pressure. If the weld seams hold, the bipolar plate is ready for the stack.