TruDiode Laser enthalten praktisch keine Verschleißteile. Das intelligente Kühlkonzept mit integriertem Wärmetauscher macht einen externen Kühler oft überflüssig. Mit dem Kühlwasser der Dioden kühlen Sie darüber auch noch Optiken und Laserlichtkabel. Zusammen mit der hohen Energieeffizienz der TruDiode Laser führt das zu sehr niedrigen Investitions- und Betriebskosten.

Sparsamer Schweißexperte

Die äußerst energieeffizienten Diodenlaser TruDiode überzeugen durch optimale Ergebnisse bei geringen Betriebskosten. Ob zum Tief-, Wärmeleit- und Auftragschweißen, Löten oder Kunststoffschweißen: Die Laser liefern exzellente Nahtqualitäten. Mit seinem modularen, platzsparenden Aufbau integrieren Sie den TruDiode leicht in Ihre Produktionssysteme. Im Lasernetzwerk versorgen Sie flexibel bis zu vier Arbeitsstationen.

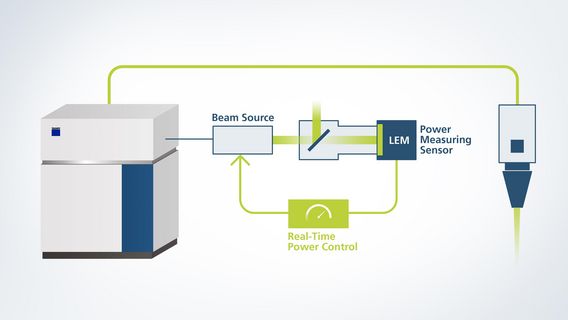

Stabile Prozesse durch integrierte, aktive Laserleistungsregelung sorgen für reproduzierbare Ergebnisse.

Der TruDiode schont Ressourcen dank hohem Wirkungsgrad und intelligentem Energiemanagement.

Der Schweißexperte fügt Kunststoffe oder Metalle und dies mit und ohne Zusatzmaterial.

Dank Diodendirekt-Prinzip überzeugt der TruDiode mit einer Aufstellfläche von deutlich unter 1m2.

Lange Lebensdauer durch passiv gekühlte Diodenmodule

Kunststoffschweißen mit TruDiode

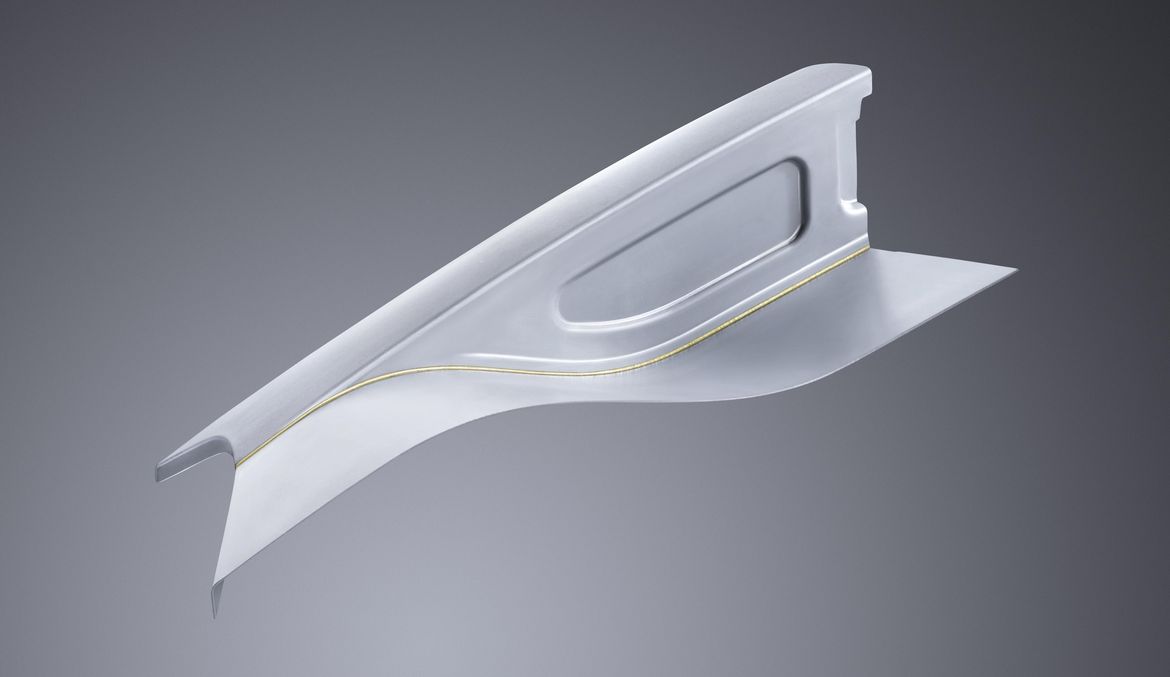

Die Diodenlaser TruDiode ermöglichen das berührungslose Schweißen von Thermoplasten mittels Durchstrahlschweißverfahren. Hierdurch erzielen Sie extrem feste, dichte und ästhetische Verbindungen. Das Durchstrahlschweißverfahren erlaubt nahezu jede Schweißgeometrie im Überlappstoß. Der genaue Energieeintrag führt nur zu minimaler thermischer und mechanischer Beanspruchung.

Löten

Beim Löten mit dem Laser werden die Fügepartner optimal mit Hilfe des Lots verbunden. Durch die geringere Schmelztemperatur des Lotwerkstoffs im Vergleich zum Bauteilwerkstoff, schmiltzt bei der Bearbeitung mit dem Laser nur das Lot. Dieses fließt in den Fügespalt und verbindet sich mit der Oberfläche des Werkstücks (Diffusionsverbindung).

|

TruDiode 151

Produkt vergleichen

|

TruDiode 301

Produkt vergleichen

|

TruDiode 603

Produkt vergleichen

|

TruDiode 903

Produkt vergleichen

|

|

|---|---|---|---|---|

| Laserparameter | ||||

| Laserleistung am Werkstück | 150 W | 300 W | 600 W | 900 W |

| Typ. Leistungskonstanz bei Nennleistung | ± 1 % | ± 1 % | ± 1 % | ± 1 % |

| Kontinuierlich einstellbarer Leistungsbereich | 3 W - 150 W | 6 W - 300 W | 12 W - 600 W | 18 W - 900 W |

| Strahlqualität | 8 mm▪mrad | 8 mm▪mrad | 16 mm▪mrad | 16 mm▪mrad |

| Numerische Apertur | 0,12 | 0,12 | 0,12 | 0,12 |

| Wellenlänge | 920 nm - 970 nm | 920 nm - 1050 nm | 920 nm - 1050 nm | 920 nm - 1050 nm |

| Min. Durchmesser Laserlichtkabel | 150 μm | 150 μm | 300 μm | 300 μm |

| Bauform | ||||

| Abmessungen (B x H x T) | - | - | 1036 mm x 1250 mm x 709 mm | 1036 mm x 1250 mm x 709 mm |

| Abmessungen, Version 19" (B x H x T) | 483 mm x 495 mm x 513 mm | 483 mm x 495 mm x 513 mm | - | - |

| Max. Anzahl Laserlichtkabel | 2 | 2 | 4 | 4 |

| Aufstellung | ||||

| Schutzart | - | - | IP54 | IP54 |

| Umgebungstemperatur | 5 °C - 40 °C | 5 °C - 40 °C | 5 °C - 45 °C | 5 °C - 45 °C |

|

TruDiode 151

|

TruDiode 301

|

TruDiode 603

|

TruDiode 903

|

|

|---|---|---|---|---|

| Laserparameter | ||||

| Laserleistung am Werkstück | 150 W | 300 W | 600 W | 900 W |

| Typ. Leistungskonstanz bei Nennleistung | ± 1 % | ± 1 % | ± 1 % | ± 1 % |

| Kontinuierlich einstellbarer Leistungsbereich | 3 W - 150 W | 6 W - 300 W | 12 W - 600 W | 18 W - 900 W |

| Strahlqualität | 8 mm▪mrad | 8 mm▪mrad | 16 mm▪mrad | 16 mm▪mrad |

| Numerische Apertur | 0,12 | 0,12 | 0,12 | 0,12 |

| Wellenlänge | 920 nm - 970 nm | 920 nm - 1050 nm | 920 nm - 1050 nm | 920 nm - 1050 nm |

| Min. Durchmesser Laserlichtkabel | 150 μm | 150 μm | 300 μm | 300 μm |

| Bauform | ||||

| Abmessungen (B x H x T) | - | - | 1036 mm x 1250 mm x 709 mm | 1036 mm x 1250 mm x 709 mm |

| Abmessungen, Version 19" (B x H x T) | 483 mm x 495 mm x 513 mm | 483 mm x 495 mm x 513 mm | - | - |

| Max. Anzahl Laserlichtkabel | 2 | 2 | 4 | 4 |

| Aufstellung | ||||

| Schutzart | - | - | IP54 | IP54 |

| Umgebungstemperatur | 5 °C - 40 °C | 5 °C - 40 °C | 5 °C - 45 °C | 5 °C - 45 °C |

Die technischen Daten aller Produktvarianten als Download.

TruControl

TruControl ist die Steuerungssoftware für Ihren TRUMPF Festkörperlaser – für die schnelle und einfache Bedienung. Pulsformen programmieren Sie individuell passend für Ihre Anwendung. Die Laserleistung wird in Echtzeit geregelt für höchste Reproduzierbarkeit Ihrer Prozessergebnisse. Um wichtige Qualitätsdaten Ihrer produzierten Teile auch nach Jahren zurückverfolgen zu können, zeichnet das optionale Software Modul DataStore alle qualitätsrelevanten Daten auf. Sind externe Steuerungen vorhanden, kommuniziert TruControl mit ihnen über alle gängigen Schnittstellen. Eingaben erfolgen über den Touchscreen des Bedienpanels oder einen Panel-Computer. Über Ethernet binden Sie Ihren Laser ins Netzwerk ein und schließen mehrere PCs an.

Mit TRUMPF haben Sie die Möglichkeit, Ihren Festkörperlaser flexibel an Ihre Einbau- und Betriebssituation anzupassen. Das gilt etwa für alle Strahlführungskomponenten und die Ansteuerung. Auch bei der Kühlwasserversorgung haben Sie mehrere Optionen. Schnittstellen für verschiedene Optiken sind bereits von vorn herein vorgesehen. Um Kosten zu sparen kann Ihre Strahlquelle auch mehrere Arbeitsstationen gleichzeitig versorgen. Der TRUMPF Remote-Service hilft Ihnen überall und jederzeit, die Verfügbarkeit Ihrer Anlagen sicherzustellen.

Unabhängig vom Alter des Lasergeräts oder den Umgebungsbedingungen wird die Laserleistung auf einem vorgegebenen Wert stabil gehalten (mit einer Abweichung von typisch ±1%). Damit sind reproduzierbare Prozessergebnisse über die gesamte Lebensdauer des Lasers sichergestellt.

Bearbeitungsoptiken und Laserlichtkabel können einfach und komfortabel über das Kühlwasser des Lasers gekühlt werden. Eine separate Kühlung ist somit nicht notwendig.

Im Störfall greifen TRUMPF Serviceexperten über eine sichere Remote-Verbindung aktiv auf Ihren Laser zu. In den meisten Fällen kann so die Störung direkt behoben oder die Konfiguration des Lasers so verändert werden, dass Sie bis zum Eintreffen des Ersatzteils weiter produzieren können. Dies ermöglicht Ihnen maximale Verfügbarkeit.

Für die Integration eines TruDiode Lasers in Ihre Maschine oder Fertigungslinie sind die Schnittstellen entscheidend. Daher bieten Festkörperlaser von TRUMPF Schnittstellen zu allen gängigen Feldbussystemen. Weiterhin sind erhältlich: Echtzeitschnittstelle, Parallel Digital I/O, Schnittstelle für Prozesssensorik, OPC UA Softwareschnittstelle, analoge Eingangskarte, Schnittstelle für intelligente TRUMPF Optiken, z.B. CFO oder PFO.

Der TruDiode verfügt über Schnittstellen zur Ansteuerung von intelligenten TRUMPF Optiken, z. B. der überwachten Fokussieroptik CFO oder der Scanneroptik PFO. Die Programmierung der Bearbeitungsoptik erfolgt bequem über die Lasersteuerung und das ohne zusätzlichen PC bzw. zusätzliche Steuerung. Ermittelte Daten und zugehörige Grenzwerte inkl. Warn- und Fehlermeldungen können in der Lasersteuerung TruControl visualisiert werden.

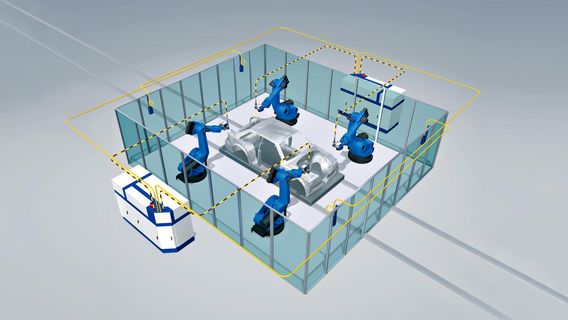

Im Lasernetzwerk vernetzen Sie einen oder mehrere TruDiode Laser mit jeweils bis zu 2 bzw. 4 Arbeitsstationen. Ihr Laser teilt dabei entweder seine Leistung auf mehrere Stationen auf oder versorgt sie mit voller Kraft abwechselnd. Das erhöht die Auslastung des Lasers, senkt die Teilekosten und erlaubt Ihnen sogar, unterschiedliche Anwendungen zu kombinieren.

Produzieren Sie jederzeit effektiv und wirtschaftlich dank TRUMPF Sensorik. Die Sensorikprodukte VisionLine, CalibrationLine oder integrierte Pyrometer stellen stabile Prozesse sicher, indem sie sämtliche Vorgänge in der Laserproduktion überwachen und so einen wichtigen Beitrag für Ihre Prozesssicherheit liefern. Die Bearbeitung läuft während der Messung ungestört weiter – Unterbrechungen sind nicht nötig. Das spart Ihnen wertvolle Produktionszeit.

Bildverarbeitung

Die TRUMPF Bildverarbeitung VisionLine erkennt Merkmale auf den Bauteilen und sorgt dafür, dass stets an der richtigen Stelle geschweißt wird.

Kalibrationswerkzeug

Das TRUMPF Kalibrationswerkzeug CalibrationLine überprüft und korrigiert in regelmäßigen, individuell definierbaren Abständen Fokuslage und Laserleistung am Werkstück.

Temperaturregelung

Die TRUMPF Temperaturregelung sorgt beim Kunststoffschweißen für optisch hochwertige Ergebnisse.

Fügewegüberwachung

Die TRUMPF Fügewegüberwachung kontrolliert beim Laserdurchstrahlschweißen von Kunststoffen das Absenken des Bauteils.

Laser und Lasersystem – bei uns ein perfektes Paar. Alle Strahlquellen sind optimal auf die Anforderungen der TRUMPF Lasersysteme abgestimmt. Wählen Sie unter zahlreichen Varianten und Optionen. So bekommen Sie eine genau auf Ihre Aufgabe zugeschnittene Anlage. Natürlich ist es auch möglich, unsere Laser direkt in Ihre Fertigungslinien zu integrieren.

TRUMPF bietet Ihnen alle Komponenten, die Sie zur Strahlführung vom Laser bis zum Werkstück benötigen. So auch diverse Fokussieroptiken, die sich in vielen Jahren industriellen Einsatzes als präzise und zuverlässig bewährt haben. Die Optiken sind leicht integrierbar - sowohl in Stand-Alone-Bearbeitungsstationen als auch in kompletten Fertigungslinien. Die TRUMPF Bearbeitungsoptiken sind perfekt auf die TRUMPF Laser abgestimmt und sind für alle Wellenlängen verfügbar.

Fokussieroptiken

Ob beim Schweißen, Schneiden, Abtragen, Aufheizen oder Bohren: Mit robusten Fokussieroptiken von TRUMPF erreichen Sie hochwertige Prozessergebnisse!

Programmierbare Fokussieroptiken

Die idealen Optiken für die Remotebearbeitung

Je nach Land sind Abweichungen von diesem Produktsortiment und von diesen Angaben möglich. Änderungen in Technik, Ausstattung, Preis und Zubehörangebot sind vorbehalten. Bitte setzen Sie sich mit Ihrem Ansprechpartner vor Ort in Verbindung, um zu erfahren, ob das Produkt in Ihrem Land verfügbar ist.