Profitieren Sie von einer Komplettlösung mit perfekt aufeinander abgestimmten Komponenten, die den das Prozessergebnis verbessern und den Integrationsaufwand reduzieren. Sie wählen aus einer Reihe von Scanneroptiken für die Remote-Bearbeitung, Fokussieroptiken für das Schweißen und Schneiden sowie einer Auswahl an Sensoren. Dadurch machen Sie Ihren Prozess so zuverlässig wie nie zuvor und erhalten ein perfekt abgestimmtes Lösungspaket. Für zusätzliche Sicherheit können Sie unseren globalen Service und den umfassenden technischen Support von uns als weltweit führenden Anbieter von Lasern und Lasersystemen nutzen.

TruFiber P - der vielseitige Faserlaser für all Ihre Schweiß- oder Schneidprozesse

Die TruFiber P Produktfamilie kommt mit vielen Funktionen und bietet Faserlaser mit bis zu 2 kW Single-Mode und bis zu 6 kW Multi-Mode. Sie können zwischen vielen verschiedenen Faserdurchmessern und -längen wählen – und haben damit immer die richtige Strahlqualität für Ihre Anwendung. In Kombination mit den TRUMPF Optik- und Sensorikprodukten bilden sie die industrielle Komplettlösung für Ihre Anwendungen.

TruFiber P bieten exzellente Prozessstabilität. Sie erhalten konstante Prozessergebnisse – zu jeder Tageszeit, das ganze Jahr über.

Immer die volle Kontrolle über den Prozess – mit flexiblen Software- und Hardwareschnittstellen.

Entwickelt für viele Jahre zuverlässigen Betrieb und das nahezu wartungsfrei.

Ein attraktives Komplettpaket mit vielen Vorteilen – zu einem Preis, der sich schnell auszahlt.

Entspricht den strengen EU- und US-amerikanischen Standards für Sicherheit und Maschinenintegration, auf die sich Integratoren und Bediener verlassen können.

Mit BrightLine Mode erzielen Sie hochwertige Schweißnähte bei minimaler Spritzerbildung.

Remote-Schweißen im Automobilbereich

Die überragende Strahlqualität von Hochleistungs-Faserlasern sorgt in Verbindung mit unseren Scanneroptiken für einen großen Scanbereich, eine hohe Bearbeitungsqualität und einen einfachen Zugang zum Schweißen dreidimensionaler Teile.

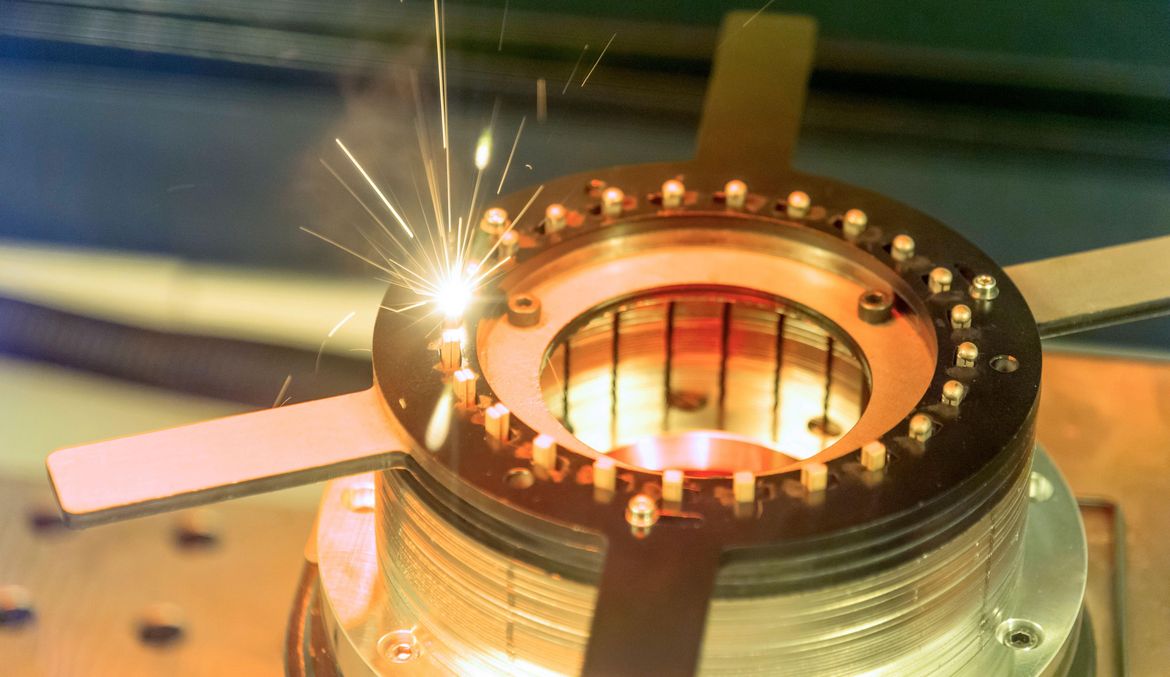

Schweißen von Getrieben

Mit Leistungen von bis zu 6 kW und hoher Strahlqualität aus Fasern mit kleinem Kerndurchmesser sind die TruFiber P Laser ideal für das Tieflochschweißen. Moderne Getriebe müssen immer kleiner und leichter werden, ohne dass die Leistung darunter leidet; oft bestehen die Teile aus unterschiedlichen Metallen. In diesem Szenario kann die Faserlaser-Technologie die passende Lösung sein, die präzise, hochfeste Schweißnähte liefert, um Leistungsteile auf wirtschaftliche Weise zu produzieren.

Schweißen von Hairpins für Elektromotoren

Anwender erzielen gleichbleibend hochfeste Verbindungen mit guter Leitfähigkeit. Intelligente Sensorik sorgt für präzise Nähte und höchste Qualität beim Schweißen von Hairpins. Das funktioniert in hohen Stückzahlen für die Serienfertigung dank hoher Reproduzierbarkeit der Laserschweißprozesse.

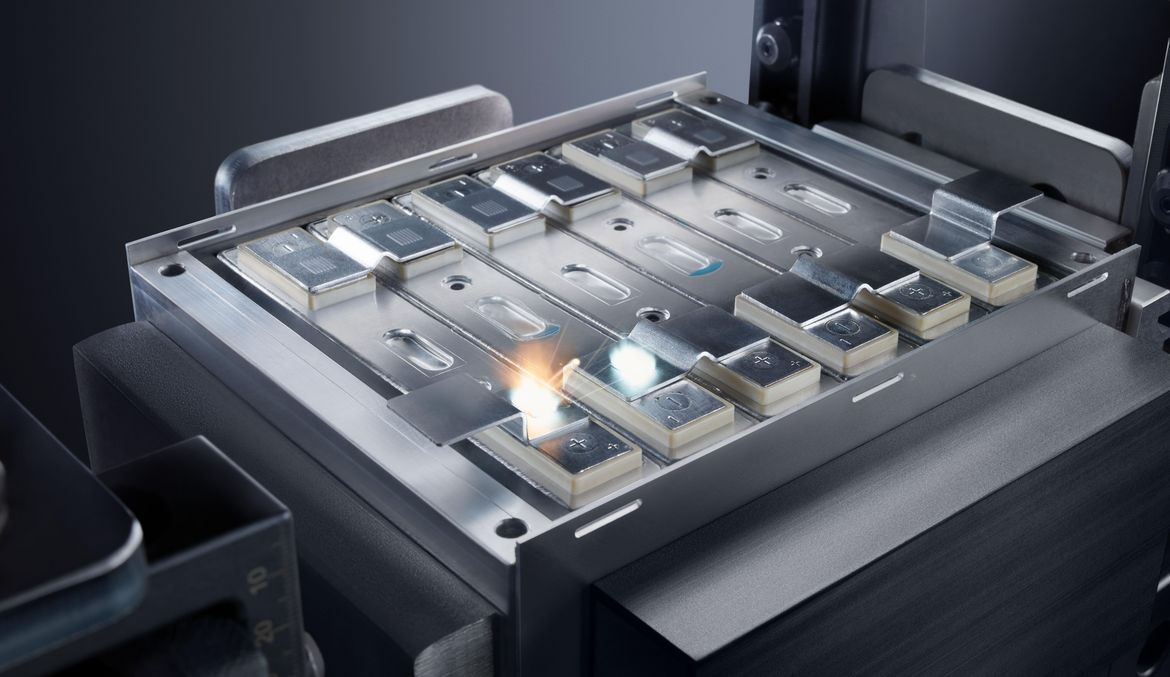

Schweißen in der Batterietechnik

Beim Busbar-Schweißen werden die einzelnen Zellen innerhalb der Batteriefertigung zu Modulen oder Packs verbunden. Eine stromführende Schiene wird als Busbar bezeichnet. Mit dem Laser können verschiedene Materialien innerhalb dieses Prozesses kombiniert werden, wie z. B. Al/Al oder Cu/Cu, aber auch Mischkombinationen, wie z. B. Al/Cu, sind möglich. Reproduzierbarkeit, minimaler Wärmeeintrag und definierte Einschweißtiefen spielen eine wichtige Rolle - all dies kann mit unseren TruFiber P Faserlaserlösungen gewährleistet werden.

Präzises Schweißen für medizinische Anwendungen

Nirgendwo ist Präzision so wichtig wie in der Medizintechnik. Mit dem TruFiber P produzieren Sie hochwertige, reproduzierbare Schweißnähte ohne Nachbearbeitung, zum Beispiel bei der Herstellung von endoskopischen Instrumenten.

Laser Metal Fusion (3D-Druck)

Laser Metal Fusion (LMF) ist ein additives Fertigungsverfahren, bei dem ein Werkstück schrittweise Schicht für Schicht aufgebaut wird, indem ein Laser das Metall auf einem Pulverbett selektiv aufschmilzt. Branchen wie Dental, Medizintechnik, Luft- und Raumfahrt- sowie die Automobilindustrie profitieren von Vorteilen wie Designfreiheit und Material- und Gewichtsreduktion. Die Single-Mode-Laser der TruFiber P Produktfamilie sind das ideale Werkzeug für den metallischen 3D-Druck.

Maßgeschneiderte Oberflächenbearbeitung und Teilereparatur

Laser Metal Deposition (LMD) ist ein additives Fertigungsverfahren, das hochwertige Beschichtungen und Verkleidungen mit Eigenschaften erzeugt, die für die spätere Anwendung des bearbeiteten Teils optimiert sind. Auch die Reparatur hochwertiger Bauteile durch den Aufbau beschädigter und abgenutzter Oberflächen ist möglich. Der Laser stellt eine lokalisierte, präzise Wärmequelle zur Verfügung, um das Füllmaterial (Pulver oder Draht) zu schmelzen, so dass es sich eng mit der Oberfläche des Teils verbindet. Die Stabilität und Genauigkeit des Laserverfahrens minimiert den Bedarf an mechanischer Nachbearbeitung, um die Nettoform der Oberfläche zu erreichen. Ein Multimode-Hochleistungslaser TruFiber P, gekoppelt mit einem abgestimmten Fokussierkopf und einer speziellen LMD-Düse, bildet die Grundlage für ein vielseitiges LMD-System.

|

TruFiber 500 P (Single Mode)

Produkt vergleichen

|

TruFiber 500 P (Multi Mode)

Produkt vergleichen

|

TruFiber 501 P

Produkt vergleichen

|

TruFiber 1000 P (Single Mode)

Produkt vergleichen

|

TruFiber 1000 P (Multi Mode)

Produkt vergleichen

|

TruFiber 1001 P

Produkt vergleichen

|

TruFiber 1500 P (Single Mode)

Produkt vergleichen

|

TruFiber 1500 P (Multi Mode)

Produkt vergleichen

|

TruFiber 1501 P

Produkt vergleichen

|

TruFiber 2000 P (Single Mode)

Produkt vergleichen

|

TruFiber 2000 P (Multi Mode)

Produkt vergleichen

|

TruFiber 2001 P

Produkt vergleichen

|

TruFiber 3000 P (Multi Mode)

Produkt vergleichen

|

TruFiber 3001 P

Produkt vergleichen

|

TruFiber 3002 P

Produkt vergleichen

|

TruFiber 4000 P (Multi Mode)

Produkt vergleichen

|

TruFiber 4001 P

Produkt vergleichen

|

TruFiber 4002 P

Produkt vergleichen

|

TruFiber 6000 P (Multi Mode)

Produkt vergleichen

|

TruFiber 6001 P

Produkt vergleichen

|

TruFiber 6002 P

Produkt vergleichen

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Laserparameter | |||||||||||||||||||||

| Laserleistung | 500 W 1 | 500 W 1 | 500 W 1 | 1000 W 1 | 1000 W 1 | 1000 W 1 | 1500 W 1 | 1500 W 1 | 1500 W 1 | 2000 W 1 | 2000 W 1 | 2000 W 1 | 3000 W 1 | 3000 W 1 | 3000 W 1 | 4000 W 1 | 4000 W 1 | 4000 W 1 | 6000 W 1 | 6000 W 1 | 6000 W 1 |

| Max. Leistungskonstanz bei Nennleistung über 8 Std. bei konstanter Umgebungstemperatur |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

| Kontinuierlich einstellbarer Leistungsbereich | 10 W - 500 W | 10 W - 500 W | 10 W - 500 W | 20 W - 1000 W | 20 W - 1000 W | 20 W - 1000 W | 30 W - 1500 W | 30 W - 1500 W | 30 W - 1500 W | 40 W - 2000 W | 40 W - 2000 W | 40 W - 2000 W | 60 W - 3000 W | 60 W - 3000 W | 60 W - 3000 W | 80 W - 4000 W | 80 W - 4000 W | 80 W - 4000 W | 120 W - 6000 W | 120 W - 6000 W | 120 W - 6000 W |

| Strahlqualität | 0,38 ± 0,03 mm▪mrad | 2,1 ± 0,3 mm▪mrad | 3,3 ± 0,4 mm▪mrad | 0,38 ± 0,03 mm▪mrad | 2,1 ± 0,3 mm▪mrad | 3,3 ± 0,4 mm▪mrad | 0,38 ± 0,03 mm▪mrad | 2,1 ± 0,3 mm▪mrad | 3,3 ± 0,4 mm▪mrad | 0,38 ± 0,03 mm▪mrad | 2,1 ± 0,3 mm▪mrad | 3,3 ± 0,4 mm▪mrad | 2,1 ± 0,3 mm▪mrad (50 µm) oder 0,4 / 4,0 mm.mrad (BrightLine Mode) | - | 8 ± 1 mm▪mrad | 2,1 ± 0,3 mm▪mrad (50 µm) oder 0,4 / 4,0 mm.mrad (BrightLine Mode) | - | 8 ± 1 mm▪mrad | 2,1 ± 0,3 mm▪mrad (50 µm) oder 0,4 / 4,0 mm.mrad (BrightLine Mode) | - | 8 ± 1 mm▪mrad |

| Wellenlänge | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 |

| Durchmesser Laserlichtkabel | 25 μm | 50 μm | 100 μm | 25 μm | 50 μm | 100 μm | 25 μm | 50 μm | 100 μm | 25 μm | 50 μm | 100 μm | 50 μm oder 25 µm / 100 µm (BrightLine Mode) | 100 μm | 200 μm | 50 μm oder 25 µm / 100 µm (BrightLine Mode) | 100 μm | 200 μm | 50 μm oder 25 µm / 100 µm (BrightLine Mode) | 100 μm | 200 μm |

| Länge Laserlichtkabel | 10 m | 20 m | 20 m | 10 m | 20 m | 20 m | 10 m | 20 m | 20 m | 10 m | 20 m | 20 m | 20 m (50 µm) oder 10 m (BrightLine Mode) | 20 m | 20 m | 20 m (50 µm) oder 10 m (BrightLine Mode) | 20 m | 20 m | 20 m (50 µm) oder 10 m (BrightLine Mode) | 20 m | 20 m |

| Bauform | |||||||||||||||||||||

| Breite | 448 mm | 448 mm | 448 mm | 448 mm | 448 mm | 448 mm | 448 mm | 448 mm | 448 mm | 448 mm | 448 mm | 448 mm | 600 mm | 600 mm | 600 mm | 600 mm | 600 mm | 600 mm | 600 mm | 600 mm | 600 mm |

| Höhe | 525 mm | 525 mm | 525 mm | 525 mm | 525 mm | 525 mm | 525 mm | 525 mm | 525 mm | 525 mm | 525 mm | 525 mm | 1000 mm | 1000 mm | 1000 mm | 1000 mm | 1000 mm | 1000 mm | 1000 mm | 1000 mm | 1000 mm |

| Tiefe | 971 mm | 971 mm | 971 mm | 971 mm | 971 mm | 971 mm | 971 mm | 971 mm | 971 mm | 971 mm | 971 mm | 971 mm | 1146 mm | 1146 mm | 1146 mm | 1146 mm | 1146 mm | 1146 mm | 1146 mm | 1146 mm | 1146 mm |

| Aufstellung | |||||||||||||||||||||

| Umgebungstemperatur | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C |

|

TruFiber 500 P (Single Mode)

|

TruFiber 500 P (Multi Mode)

|

TruFiber 501 P

|

TruFiber 1000 P (Single Mode)

|

TruFiber 1000 P (Multi Mode)

|

TruFiber 1001 P

|

TruFiber 1500 P (Single Mode)

|

TruFiber 1500 P (Multi Mode)

|

TruFiber 1501 P

|

TruFiber 2000 P (Single Mode)

|

TruFiber 2000 P (Multi Mode)

|

TruFiber 2001 P

|

TruFiber 3000 P (Multi Mode)

|

TruFiber 3001 P

|

TruFiber 3002 P

|

TruFiber 4000 P (Multi Mode)

|

TruFiber 4001 P

|

TruFiber 4002 P

|

TruFiber 6000 P (Multi Mode)

|

TruFiber 6001 P

|

TruFiber 6002 P

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Laserparameter | |||||||||||||||||||||

| Laserleistung | 500 W 1 | 500 W 1 | 500 W 1 | 1000 W 1 | 1000 W 1 | 1000 W 1 | 1500 W 1 | 1500 W 1 | 1500 W 1 | 2000 W 1 | 2000 W 1 | 2000 W 1 | 3000 W 1 | 3000 W 1 | 3000 W 1 | 4000 W 1 | 4000 W 1 | 4000 W 1 | 6000 W 1 | 6000 W 1 | 6000 W 1 |

| Max. Leistungskonstanz bei Nennleistung über 8 Std. bei konstanter Umgebungstemperatur |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

± 1 % ohne aktive Leistungsregelung

± 0,5 % bei aktiver Leistungsregelung |

| Kontinuierlich einstellbarer Leistungsbereich | 10 W - 500 W | 10 W - 500 W | 10 W - 500 W | 20 W - 1000 W | 20 W - 1000 W | 20 W - 1000 W | 30 W - 1500 W | 30 W - 1500 W | 30 W - 1500 W | 40 W - 2000 W | 40 W - 2000 W | 40 W - 2000 W | 60 W - 3000 W | 60 W - 3000 W | 60 W - 3000 W | 80 W - 4000 W | 80 W - 4000 W | 80 W - 4000 W | 120 W - 6000 W | 120 W - 6000 W | 120 W - 6000 W |

| Strahlqualität | 0,38 ± 0,03 mm▪mrad | 2,1 ± 0,3 mm▪mrad | 3,3 ± 0,4 mm▪mrad | 0,38 ± 0,03 mm▪mrad | 2,1 ± 0,3 mm▪mrad | 3,3 ± 0,4 mm▪mrad | 0,38 ± 0,03 mm▪mrad | 2,1 ± 0,3 mm▪mrad | 3,3 ± 0,4 mm▪mrad | 0,38 ± 0,03 mm▪mrad | 2,1 ± 0,3 mm▪mrad | 3,3 ± 0,4 mm▪mrad | 2,1 ± 0,3 mm▪mrad (50 µm) oder 0,4 / 4,0 mm.mrad (BrightLine Mode) | - | 8 ± 1 mm▪mrad | 2,1 ± 0,3 mm▪mrad (50 µm) oder 0,4 / 4,0 mm.mrad (BrightLine Mode) | - | 8 ± 1 mm▪mrad | 2,1 ± 0,3 mm▪mrad (50 µm) oder 0,4 / 4,0 mm.mrad (BrightLine Mode) | - | 8 ± 1 mm▪mrad |

| Wellenlänge | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 | 1071 nm ± 2 |

| Durchmesser Laserlichtkabel | 25 μm | 50 μm | 100 μm | 25 μm | 50 μm | 100 μm | 25 μm | 50 μm | 100 μm | 25 μm | 50 μm | 100 μm | 50 μm oder 25 µm / 100 µm (BrightLine Mode) | 100 μm | 200 μm | 50 μm oder 25 µm / 100 µm (BrightLine Mode) | 100 μm | 200 μm | 50 μm oder 25 µm / 100 µm (BrightLine Mode) | 100 μm | 200 μm |

| Länge Laserlichtkabel | 10 m | 20 m | 20 m | 10 m | 20 m | 20 m | 10 m | 20 m | 20 m | 10 m | 20 m | 20 m | 20 m (50 µm) oder 10 m (BrightLine Mode) | 20 m | 20 m | 20 m (50 µm) oder 10 m (BrightLine Mode) | 20 m | 20 m | 20 m (50 µm) oder 10 m (BrightLine Mode) | 20 m | 20 m |

| Bauform | |||||||||||||||||||||

| Breite | 448 mm | 448 mm | 448 mm | 448 mm | 448 mm | 448 mm | 448 mm | 448 mm | 448 mm | 448 mm | 448 mm | 448 mm | 600 mm | 600 mm | 600 mm | 600 mm | 600 mm | 600 mm | 600 mm | 600 mm | 600 mm |

| Höhe | 525 mm | 525 mm | 525 mm | 525 mm | 525 mm | 525 mm | 525 mm | 525 mm | 525 mm | 525 mm | 525 mm | 525 mm | 1000 mm | 1000 mm | 1000 mm | 1000 mm | 1000 mm | 1000 mm | 1000 mm | 1000 mm | 1000 mm |

| Tiefe | 971 mm | 971 mm | 971 mm | 971 mm | 971 mm | 971 mm | 971 mm | 971 mm | 971 mm | 971 mm | 971 mm | 971 mm | 1146 mm | 1146 mm | 1146 mm | 1146 mm | 1146 mm | 1146 mm | 1146 mm | 1146 mm | 1146 mm |

| Aufstellung | |||||||||||||||||||||

| Umgebungstemperatur | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C |

Die technischen Daten aller Produktvarianten als Download.

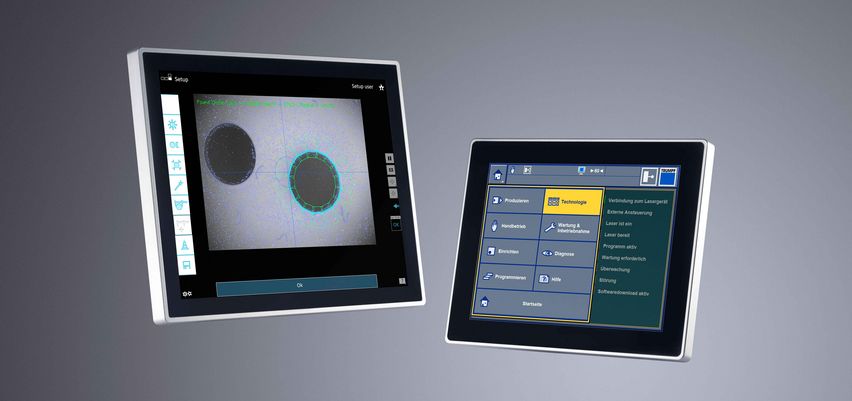

TruControl

TruControl ist die schnelle und einfach bedienbare Steuerung für TRUMPF Festkörperlaser. Sie regelt die Laserleistung in Echtzeit für reproduzierbare Ergebnisse. Zusätzliche Module sind speziell auf die Anforderungen des TruFiber zugeschnitten. So passt die Option CutAssist automatisch die Laserparameter an die Bahngeschwindigkeit der Führungsanlage an. Um die Rückverfolgbarkeit von Teilen zu gewährleistet, zeichnet das Modul DataStore alle qualitätsrelevanten Daten auf.

Sind externe Steuerungen vorhanden, kommuniziert TruControl mit Ihnen über alle gängigen Schnittstellen. Eingaben erfolgen über den Touchscreen des Bedienpanels oder einen Panel-Computer. Über Ethernet binden Sie Ihren Laser ins Netzwerk ein und schließen mehrere PCs an.

Smart Teach App

Mit der PFO Smart Teach App erstellen Sie im Handumdrehen Laserprogramme für Ihre programmierbare Fokussieroptik (PFO). Ob Laserschweißen, Laserschneiden oder Laserreinigen - Sie teachen komfortabel direkt am Bauteil. Dazu überträgt sie an die PFO eingebaute Kamera Livebilder an die App. Dank PFO SmartTeach sparen Sie beim Einrichten wertvolle Zeit, je nach Bauteil bis zu 50 % gegenüber konventionellem Teachen.

100 % konstante Prozessergebnisse: Die integrierte Laserleistungsregelung misst und regelt die Leistung in Echtzeit auf +/- 1 % genau. Auf diese Weise erhalten Sie immer dieselben Prozessergebnisse. Die Regelung der Laserleistung erfolgt dabei unabhängig von der Umgebungsbedingung. Dank seines besonders robusten Konzepts hält der TruFiber Störeinflüssen und äußerlichen Beanspruchungen extrem gut stand.

Mit BrightLine Mode können Materialien wie Kupfer, Aluminium und Edelstahl nahezu spritzerfrei geschweißt werden. Das patentierte 2-in-1-Laserlichtkabel (LLK) mit Single-Mode-Kern und Multi-Mode-Ring ist robust mit dem Laser verspleißt. TruControl ermöglicht eine dynamische Anpassung der Leistungsverteilung im Ring und Kern des LLK für optimale Ergebnisse bei Schweißanwendungen.

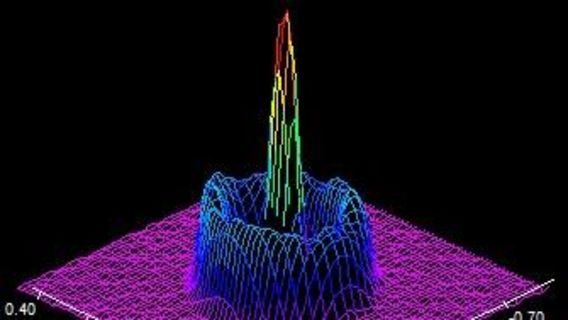

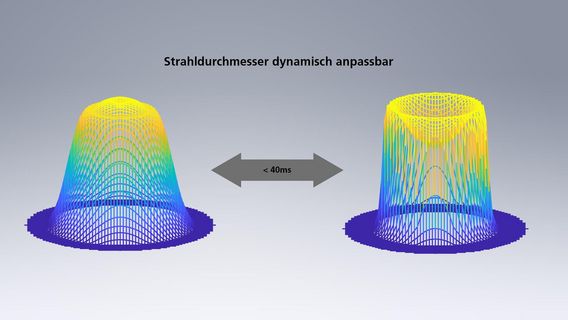

Mit der Funktion VariMode können Sie die Strahlcharakteristik Ihres Faserlasers (ab 3 kW mit 100 μm Faser) an Ihre Anwendung anpassen. Vor allem das Strahlparameterprodukt (BPP), aber auch das Strahlprofil und die Leistungsdichte auf dem Werkstück können variiert werden. Dieses dynamisch steuerbare Strahlprofil bringt erhebliche Vorteile mit sich und ermöglicht "on the fly" Änderungen der Bearbeitungsschritte, um die Produktionsgeschwindigkeit zu erhöhen, die Kosten zu senken und die Prozessqualität für eine Reihe von Schneid- und Schweißanwendungen zu verbessern.

Über eine eigene Schnittstelle synchronisieren Sie intelligente Optiken mit Ihrem Laser. So können Sie die Scanneroptik PFO optimal für Ihre Zwecke nutzen. Die Programmierung der Bearbeitungsoptik erfolgt bequem über die Lasersteuerung. Wobbelgeometrien können zum Beispiel direkt der Bahngeometrie überlagert werden. Zusätzliche Steuerungen sind unnötig.

Für die Integration eines TruFiber Lasers in Ihre Maschine oder Fertigungslinie sind die Schnittstellen entscheidend. Daher bieten Festkörperlaser von TRUMPF Schnittstellen zu allen gängigen Feldbussystemen. Weiterhin sind erhältlich: Echtzeitschnittstelle, Parallel Digital I/O, Schnittstelle für Prozesssensorik, OPC UA Softwareschnittstelle, analoge Eingangskarte, Schnittstelle für intelligente TRUMPF Optiken (CFO, PFO).

Im Störungsfall greifen TRUMPF Serviceexperten über eine sichere Remote-Verbindung aktiv auf Ihren Laser zu. Häufig wird auf diese Weise die Störung direkt behoben oder die Konfiguration des Lasers so verändert, dass Sie bis zum Eintreffen des Ersatzteils weiter produzieren können.

Durch den Umgebungsschutz des Lasers (Schutzart IP54) mit integrierter Schrankklimatisierung, in Verbindung mit dem weiten Spezifikationsbereich für die Kühlmitteltemperatur, kann der TruFiber P von TRUMPF in unterschiedlichen Umgebungsbedingungen zuverlässig eingesetzt werden.

Bildverarbeitung

Die TRUMPF Bildverarbeitung VisionLine erkennt Merkmale auf den Bauteilen und sorgt dafür, dass stets an der richtigen Stelle geschweißt wird.

Kalibrationswerkzeug

Das TRUMPF Kalibrationswerkzeug CalibrationLine überprüft und korrigiert in regelmäßigen, individuell definierbaren Abständen Fokuslage und Laserleistung am Werkstück.

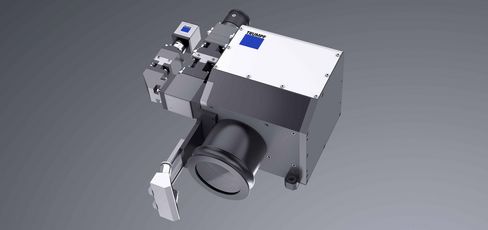

Programmierbare Fokussieroptiken

Remoteschweißen und -schneiden mit der programmierbaren Fokussieroptik. Mit den robusten Fokussieroptiken von TRUMPF können Sie sich auf hochwertige Prozessergebnisse verlassen.

Fokussieroptiken

Ob beim Schweißen, Schneiden, Abtragen, Aufheizen oder Bohren: Mit robusten Fokussieroptiken von TRUMPF erreichen Sie hochwertige Prozessergebnisse!

Je nach Land sind Abweichungen von diesem Produktsortiment und von diesen Angaben möglich. Änderungen in Technik, Ausstattung, Preis und Zubehörangebot sind vorbehalten. Bitte setzen Sie sich mit Ihrem Ansprechpartner vor Ort in Verbindung, um zu erfahren, ob das Produkt in Ihrem Land verfügbar ist.

Fußnoten-

Die Laserleistung am Werkstück kann je nach Optikkonfiguration von der Nennleistung abweichen.