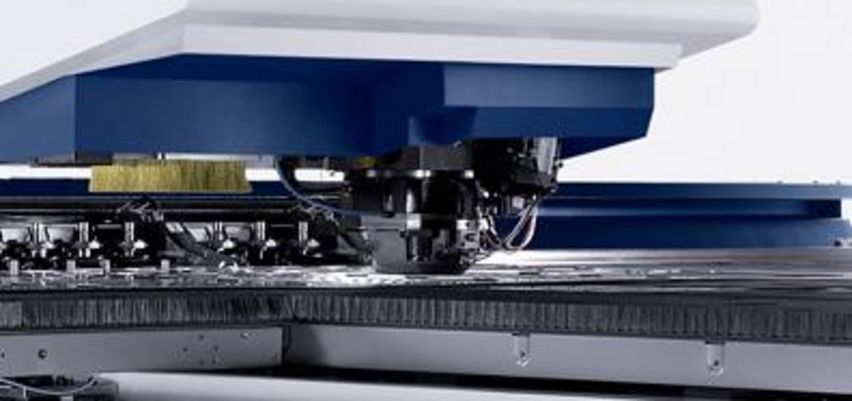

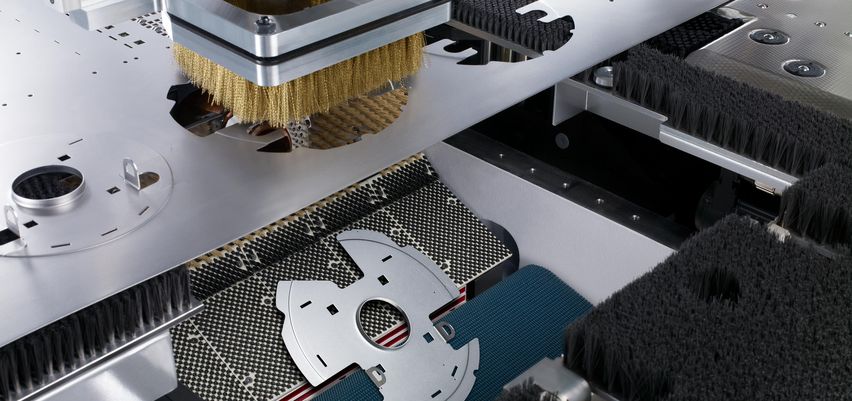

The electro-hydraulic punching head completely processes parts and generally makes downstream working steps, such as deburring, unnecessary.

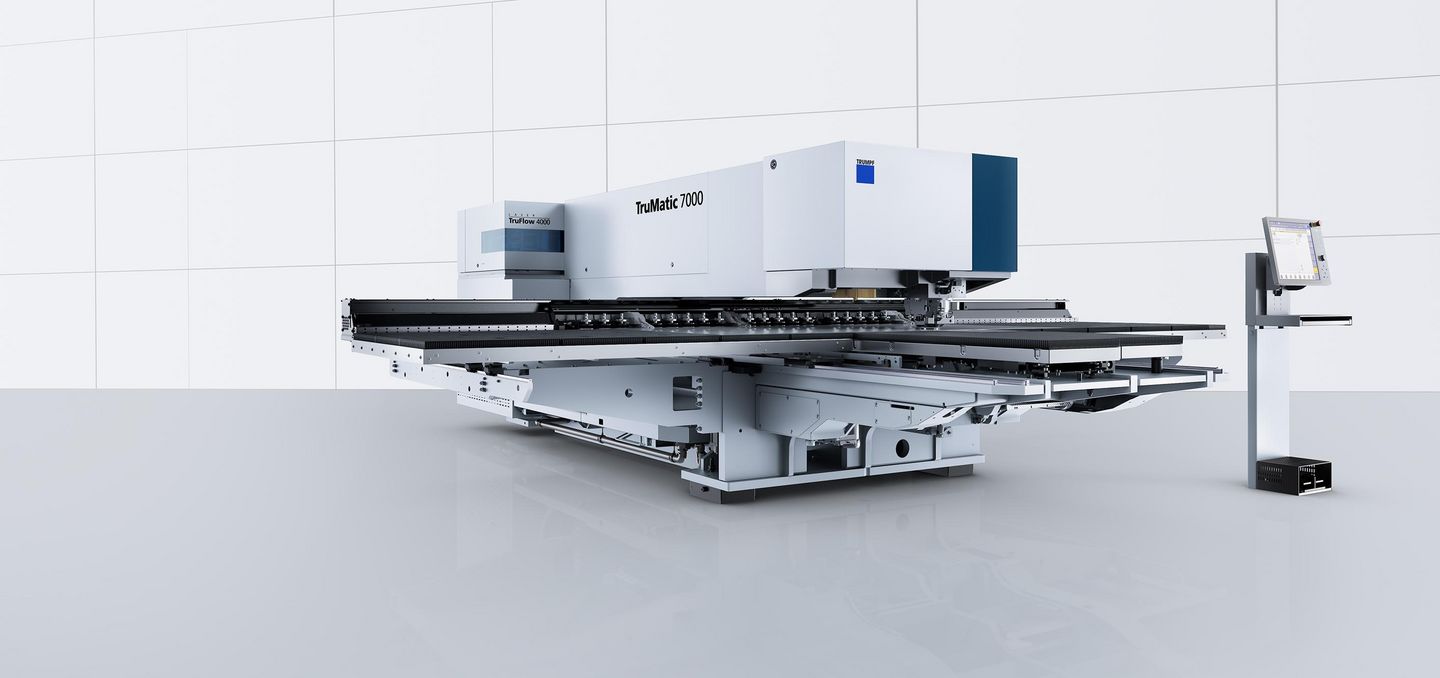

Productive high-end machine

The TruMatic 7000 brings together the advantages of punch and laser processing in a particularly cost-efficient way. The high-end punch laser machine meets high demands in regards to part quality, productivity, and flexibility. With the active die, you can produce scratch-free parts and profit from the greatest level of flexibility when forming.

The active die provides you with scratch-free processing and new forming options due to the active forming stroke from below.

The CO2 laser guarantees high-precision cutting results through outstanding beam quality.

The additional axes provide a clear productivity gain – right up to extremely high levels of productivity.

The automatic nozzle changer removes the old nozzle for new orders, and inserts a new one, saving time in automated operation.

You can remove parts in a process reliable way via sensor-protected flaps.

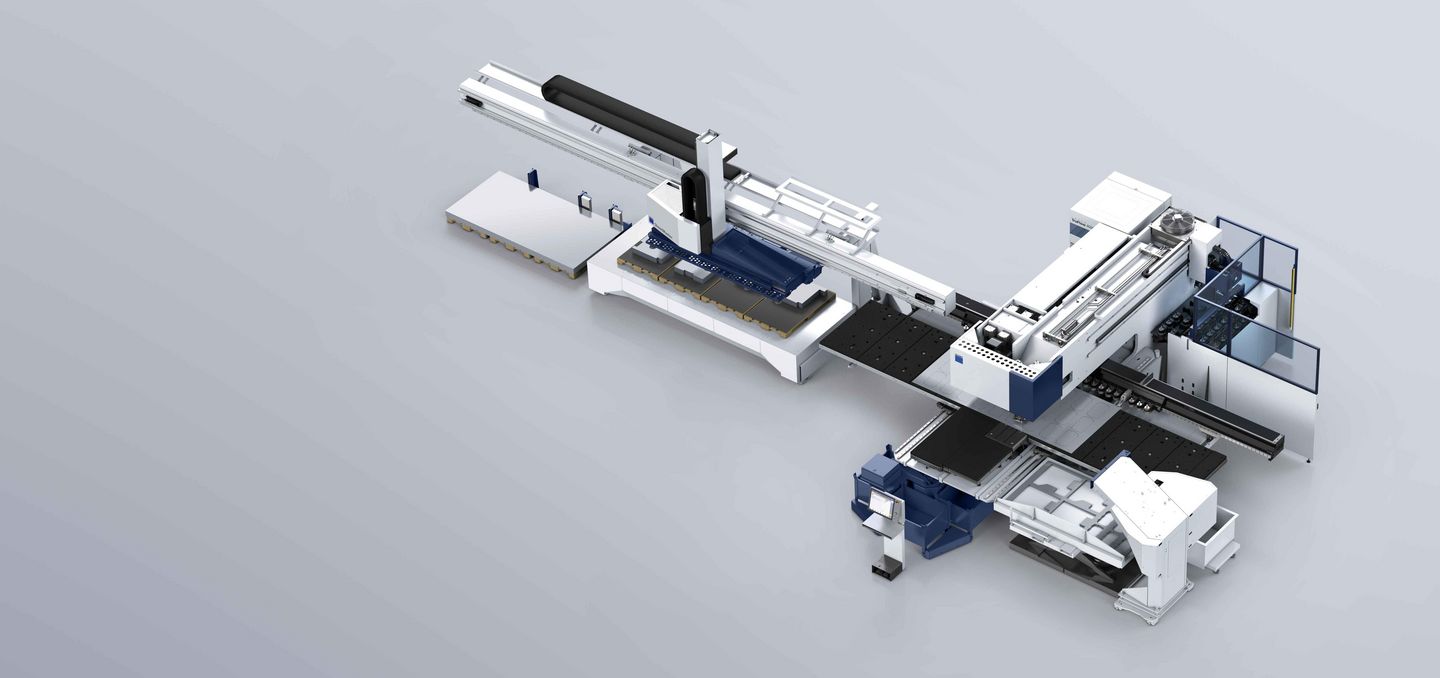

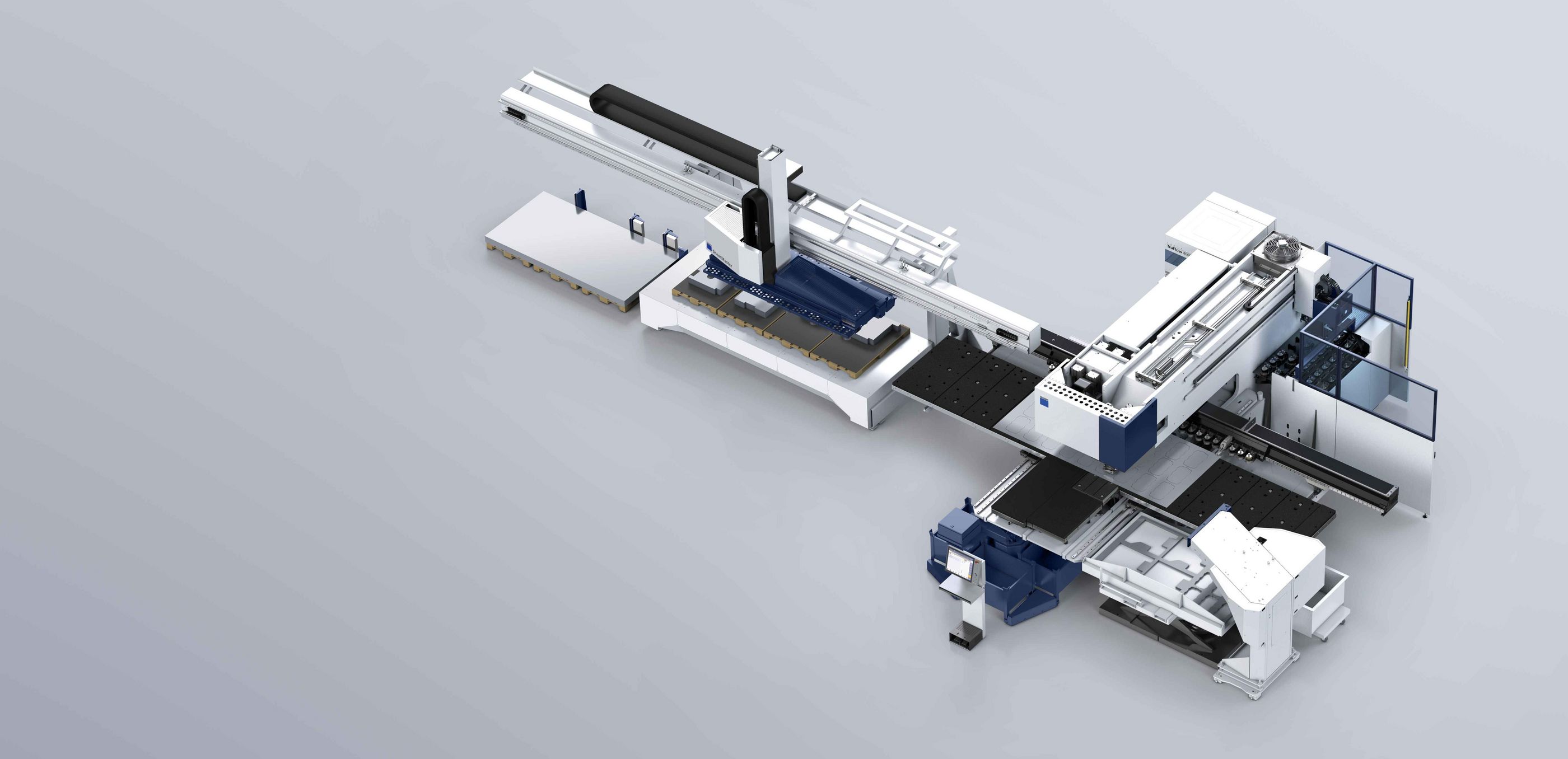

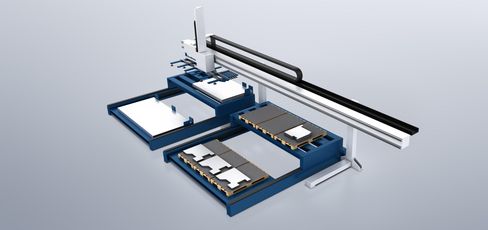

With the SheetMaster, you can load, unload, and sort parts in a process reliable and automated way.

Flexible forming

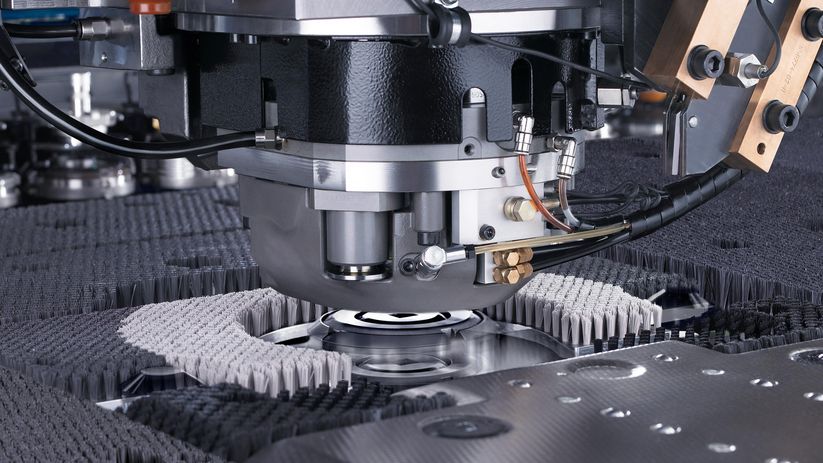

With the active forming die from below, you can achieve sizes and heights that were previously unattainable. The 360° rotation of the punching head also provides you with flexible processing options.

Using the laser, you can cut high-quality outer contours and delicate inner contours.

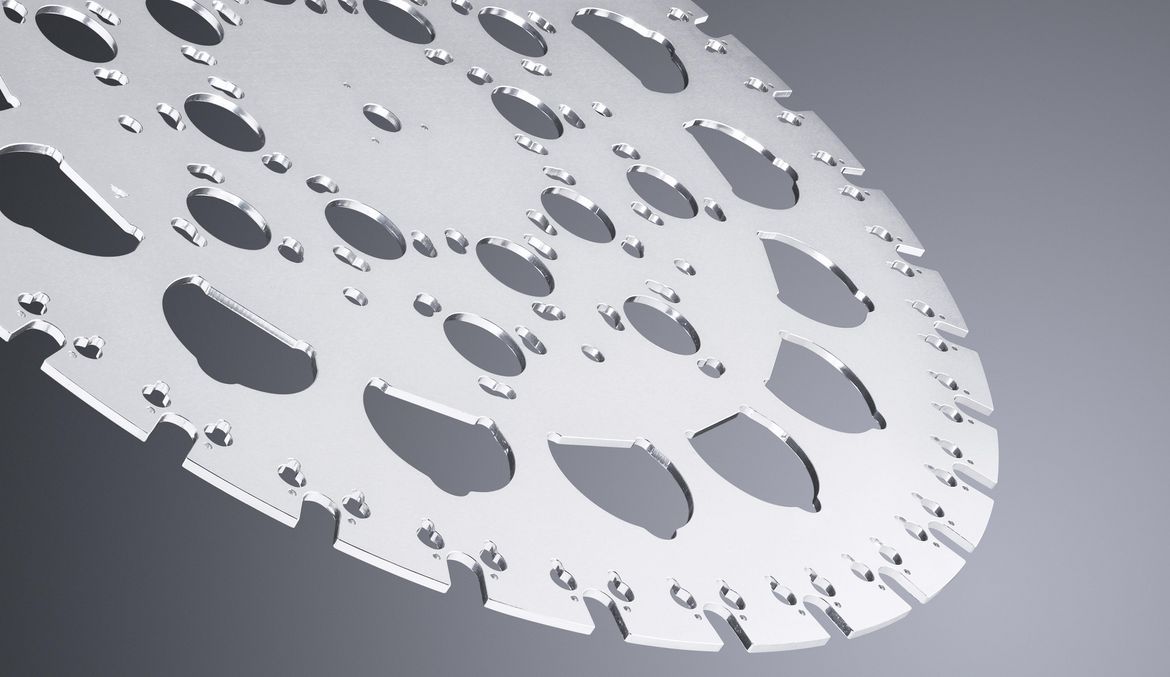

For this component, the following tools were used: cup tool, extrusion tool, tapping tool, embossing tool – symbol (underside of the sheet), bridge tool, MultiBend size 5, and positioning tool size 5.

Wide range of contour flexibility

Process sheets up to 0.3 inches thick with a wide range of contour flexibility, including tapping, countersinking, and weld positioning.

For this component, the following tools were used: embossing tool, countersink forming tool, tapping tool, center boss tool, special punching tool.

Impressive possibilities

With the options of roller technology and tapping, you can also produce complex components.

For this component, the following tools were used amongst others: Extrusion tool from below, cluster tool, MultiBend, roller offset tool, roller beading tool.

Small contours, delicate parts

The additional axes of the TruMatic 7000 ensure maximum productivity when processing sheet metal. As such, even small contours or delicate parts can be efficiently cut.

|

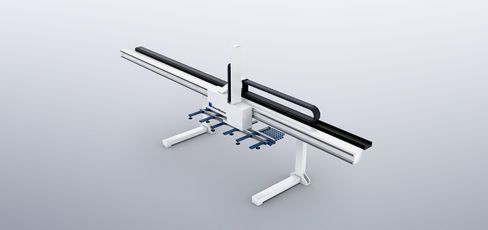

TruMatic 7000 large format

|

TruMatic 7000 medium format

|

|

|---|---|---|

| Dimensions | ||

| Width | 10190 mm 1 | 10190 mm 1 |

| Depth | 8898 mm 1 | 8450 mm 1 |

| Height | 2328 mm 1 | 2328 mm 1 |

| Maximum stroke rate | ||

| Punching (E = 1 mm) | 1200 1/min | 1200 1/min |

| Marking | 3000 1/min | 3000 1/min |

| Working range | ||

| Punching mode, X axis | 3050 mm | 2500 mm |

| Punching mode, Y axis | 1550 mm | 1250 mm |

| Laser operation, X axis | 3050 mm | 2500 mm |

| Laser operation, Y axis | 1550 mm | 1250 mm |

| Combined operation, X axis | 2500 mm | 2500 mm |

| Combined operation, Y axis | 1550 mm | 1250 mm |

| Maximum sheet thickness | 8 mm | 8 mm |

| Maximum workpiece weight | 280 kg | 200 kg |

| Maximum punching force | 220 kN | 220 kN |

| Tools | ||

| MultiTool tool changing time | 0.3 s | 0.3 s |

| Number of tools/clamps | 21 pieces / 4 pieces | 22 pieces / 3 pieces |

| Laser-specific data - TruFlow 4000 | ||

| Maximum laser power | 4000 W | 4000 W |

| Maximum sheet thickness, mild steel | 8 mm | 8 mm |

| Maximum sheet thickness, stainless steel | 8 mm | 8 mm |

| Maximum sheet thickness, aluminum | 6 mm | 6 mm |

| Part removal | ||

| Maximum part size, part removal flap, punching | 500 mm x 500 mm | 500 mm x 500 mm |

| Maximum part size, fixed chute, punching (with moving table) | 80 mm x 50 mm | 80 mm x 50 mm |

| Maximum part size, part removal flap, laser | 500 mm x 500 mm | 500 mm x 500 mm |

| Consumption values | ||

| Average power input in production - TruFlow 4000 | 28.5 kW | 28.5 kW |

| Auto-shutdown active - TruFlow 4000 | 1.5 kW | 1.5 kW |

The technical data of all product versions as a download.

The TruMatic 7000 meets the highest demands regarding part quality, productivity, and flexibility. Numerous options and automation possibilities provide you with all of the options afforded by modern punch laser processing.

Quality

The active die enables scratch-free punching and forming processes. The die can be lowered during positioning so the sheet does not have any contact with the die – for both punching as well as higher forming dies. When forming downward, there is no longer a risk of things getting caught. In addition, you can perform strokes from below with the active die, expanding your range of forming options.

For sensitive materials, which must not have any scratches underneath, you can use brush tables combined with the active die. Parts which are to be subsequently painted, can also be processed on the handy ball table.

Productivity

If, to process a new order, the machine needs a different cutting nozzle, the automatic nozzle changer removes the old nozzle and inserts a new one from the nozzle magazine. In shift operation, this is particularly useful: Your machine can operate independently.

Process reliability

Smart load supports sheet alignment on the machine. A sensor in the clamps detects when they do not grip the sheet correctly. If this is the case, the machine table, including sheet, moves.

If a finished part does not fall through the part removal flap as expected, a sensor detects this and it is rectified by the machine. Your part is detached and is removed safely.

Before the tool change, smart punch monitoring checks whether a hole was actually punched into the sheet. In this way, the machine detects at an early stage when punches are broken, and can pass this information on to the operator. This means that you can avoid rejects, particularly during night and weekend shifts.

Seamless integration of multiple TRUMPF machines into your own software environment is very easy. We have the right solution for every combination, whether it be integration into Oseon or a connection to monitoring and analysis tools. A connection to third-party software systems is also possible with our interfaces based on the OPC UA standard.

Cost-effectiveness

During the punching of sheet metal, compression and tensile stresses are placed on the workpiece which can cause sheet deformation. The integrated flattening machine function and the corresponding tool make it possible to even out surface irregularities during the punching process itself.

Flexibility

With the MobileControl app from TRUMPF you can operate and monitor your machines easily and with flexibility as the app transmits the interface of the standard control panel onto the touch screen of your tablet PC. In addition to the static control panel, you have another option for monitoring and controlling your machine.

The machine is available in a large and medium format as desired. The large format enables your sheet metal to be processed in a working area of up to 120 x 60 in. This increases the number of potential part geometries, thereby offering you even greater flexibility.

TruTops Boost

Construct and program your laser, punching, and combined punch laser machines intelligently with TruTops Boost, your all-in-one 3D solution. Numerous automated processes save you time-consuming routine processes and the joint nesting pool saves time and material. You also always have an overview of all manufacturing orders and order-based work.

Software

The software portfolio from TRUMPF optimizes your entire production process – from the customer query through to delivery of the finished part. TRUMPF combines the software intelligently with machines and services to create customized Industry 4.0 solutions for your Smart Factory.

With the cluster tool for integrated flattening, punching and flattening can be performed in a single operation. As a result, not only do the workpieces remain completely distortion-free, you also save a lot of time.

For separating protective film from sheets directly on the machine.

TRUMPF offers the world's largest range of punching tools on the market. You will find the perfect solution for every punching and forming application.

With the automation of your TruMatic 7000 fiber, you profit from higher machine utilization, and increased process reliability in automated multiple-shift operation. Custom-fit automation solutions provide clarity in your processes – you produce more cost-effectively and gain financial flexibility.

Loading + unloading + sorting

The SheetMaster guarantees the fast and process-reliable loading, unloading, unstacking, and sorting of your finished parts.

Loading + unloading

Cart systems with belt drives for loading and unloading are the tailored solution for expanding your SheetMaster. Unprocessed sheets are automatically provided for loading onto the machine, and a connection to different storage systems is created.

Sorting

The SortMaster Box automatically sorts small parts which are removed via the punching or laser flap.

Disposal

The GripMaster ensures convenient scrap skeleton handling. It removes scrap skeletons and remainder strips automatically and stacks them on a scissor table.

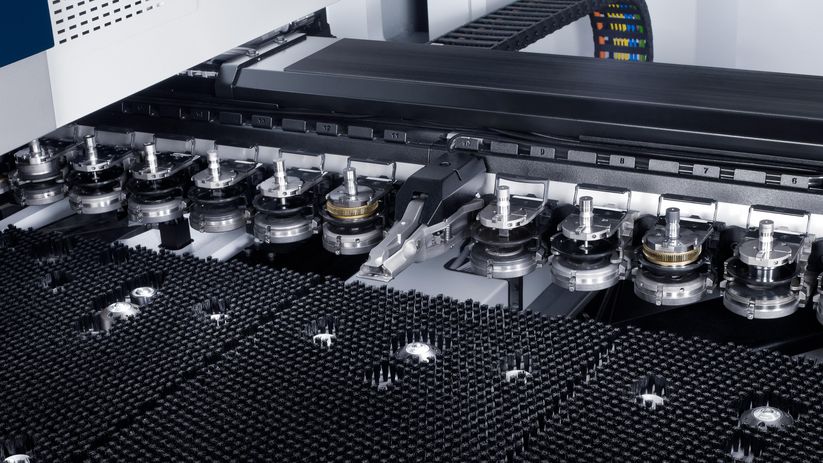

Tool handling

The ToolMaster Linear also provides space for an additional 18, 54 or 90 tools which are automatically positioned in the linear magazine of your machine. This means you can complete even complex orders with numerous tool changes quickly and automatically.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

Footnotes-

The dimensions are approximate; the dimensions specified in the installation plan are valid.