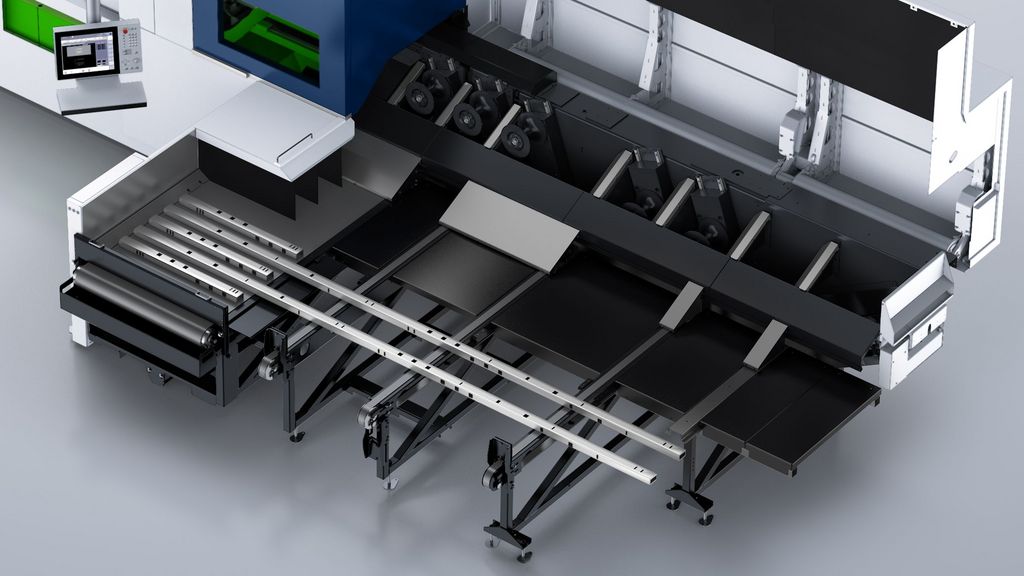

The LoadMaster Tube minimizes your setup times. Its bundle space accommodates up to 4 t of raw material. It ensures that the correct tubes were loaded before supplying the material.

The advantages of our laser tube cutting machines

The economic pressure in conventional tube processing is increasing. The laser can save you entire process steps – and money too. At the same time, you can expand your range of parts and therefore your customer base. As a market leader in laser technology and the machine tool industry, we are the innovative trendsetters in the market, offering you perfect solutions when it comes to laser tube cutting.

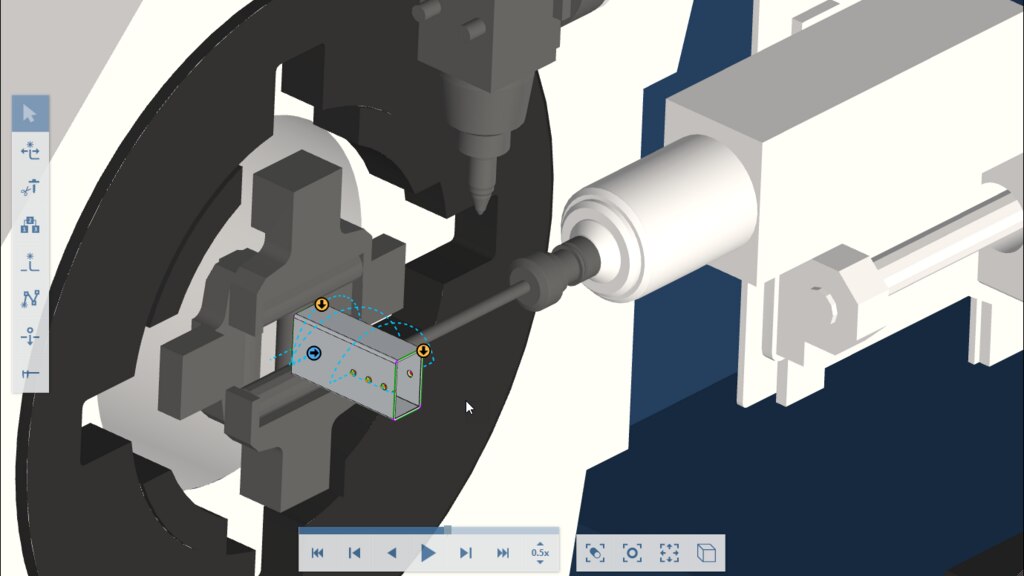

1. Loading

Your metal tubes and metal profiles begin their journey through the TruLaser Tube machines with the loading process. Short setup times, very good accessibility and a practical machine concept with many functions make part handling quick and easy.

Find out more2. Cutting

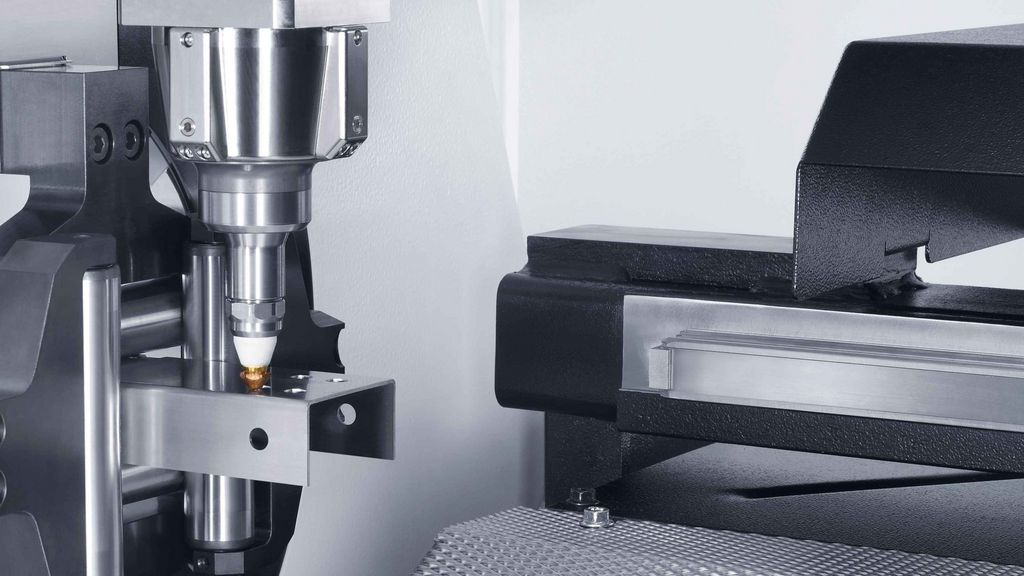

Top quality while saving time and protecting the material: numerous options make it possible for you to cut your metal tubes and profiles with the TruLaser Tube

Find out more3. Unloading

The TruLaser Tube is extremely efficient even when unloading, demonstrating the same benefits it displays during loading – clever solutions, good accessibility, ergonomics.

Find out more4. Software

TRUMPF provides software, not just for programming, but also for production management and for a well-run, smooth process.

Find out more1. Loading

2. Cutting

3. Unloading

4. Software

A world of tubes

A different way of designing:

You produce complete assemblies with meaningful tube designs. With the pressure in conventional tube processing mounting, you are saving time and money – and tapping into new customer groups.

We see tubes every day, more than we realize...

...which is exactly what makes laser tube cutting so profitable: the many application options and efficient processing with TRUMPF machines.

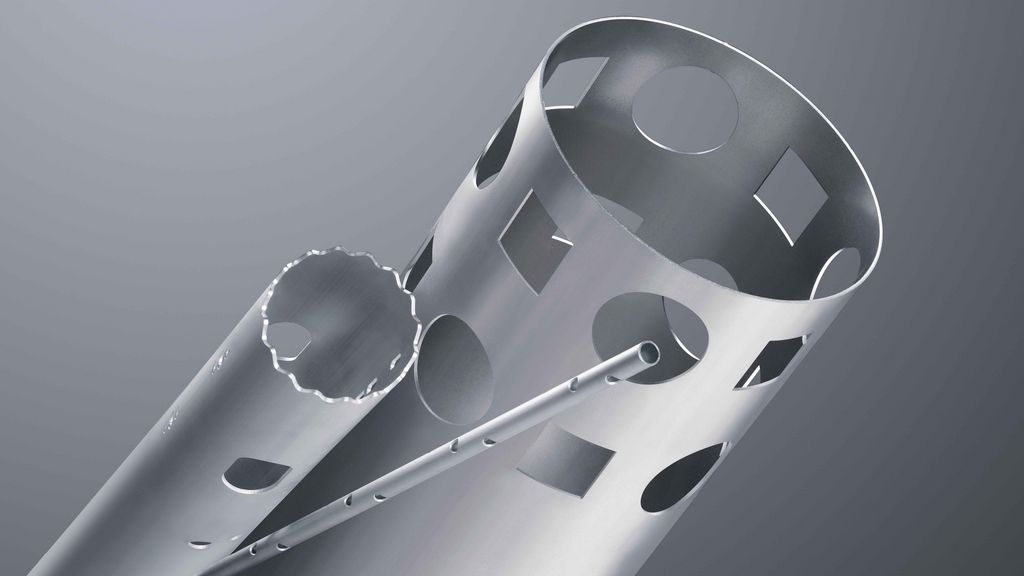

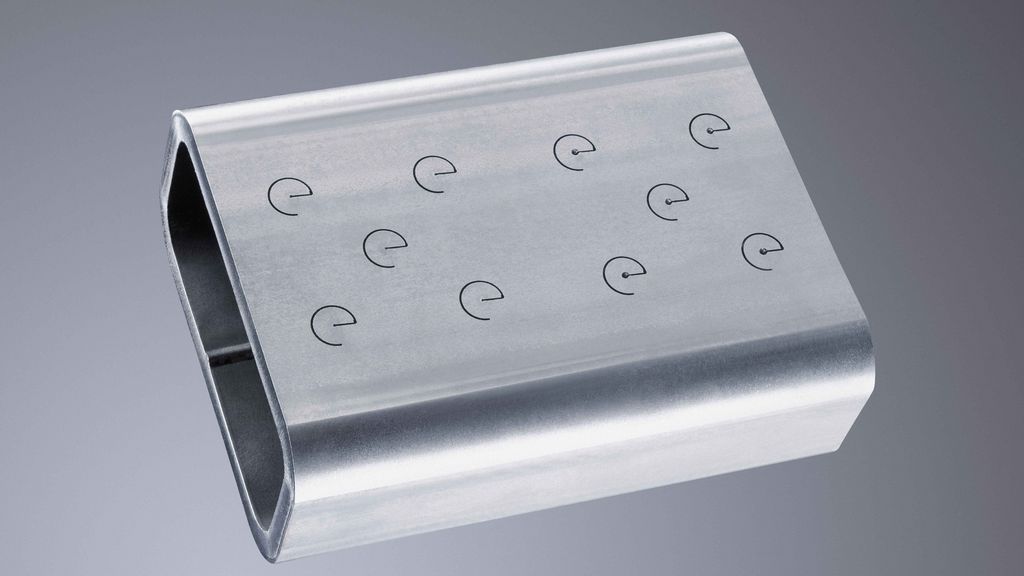

- Make the most of the freedom of contours: you can cut any geometry with the laser beam. It is easy to operate the TruTops machines, meaning you are ready for small lot sizes in no time at all.

- Save tools: you only need one tool – your TRUMPF laser. It processes different material types, wall thicknesses and profile geometries. No tool changes are needed.

- Cap part costs: laser tube cutting eliminates entire process steps like sawing, drilling or milling. With the right TRUMPF functions, you can also form threads directly in the TruLaser Tube – lowering the expenditure for handling and storage as well. Your part costs are significantly lowered compared to conventional tube processing.

An altogether excellent setup – including excellent advice and consultation

Consultation for part design

How can you process your assemblies and subassemblies in the most efficient manner? How do you conquer unfamiliar part territory? We answer these questions in a consultation about part design – in a workshop at TRUMPF or at your facility. Lower your part costs and inspire your customers with new ideas!