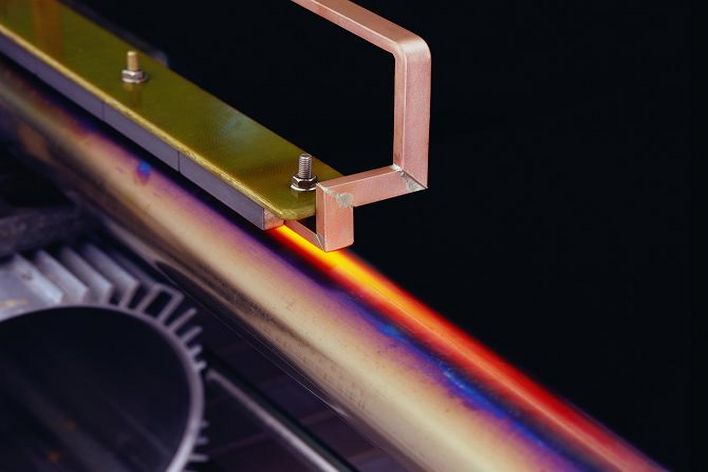

Tubes for holding different types of contents in the cosmetics, medical and food industries usually have a bidirectional coated-aluminum barrier to protect substrates from light, moisture and oxygen and prevents the loss of ingredients, odor and taste. This layer can be inductively heated, melting the coating and enabling welding. The process is used for making tube bodies with longitudinal seams as well as for sealing tube crimps after filling. Welding temperatures are reached within a fraction of a second enabling very short cycle times without affecting the substrate. TRUMPF Hüttinger generators with 5kW output and several hundred kHz provide the necessary process power.

Induction welding

Induction tube welding

Products

TruHeat HF Series 1000 / 3000 / 5000

High power, compact format

TruHeat HF Series 1000 / 3000 / 5000 H

Small external circuit - big impact

Contact