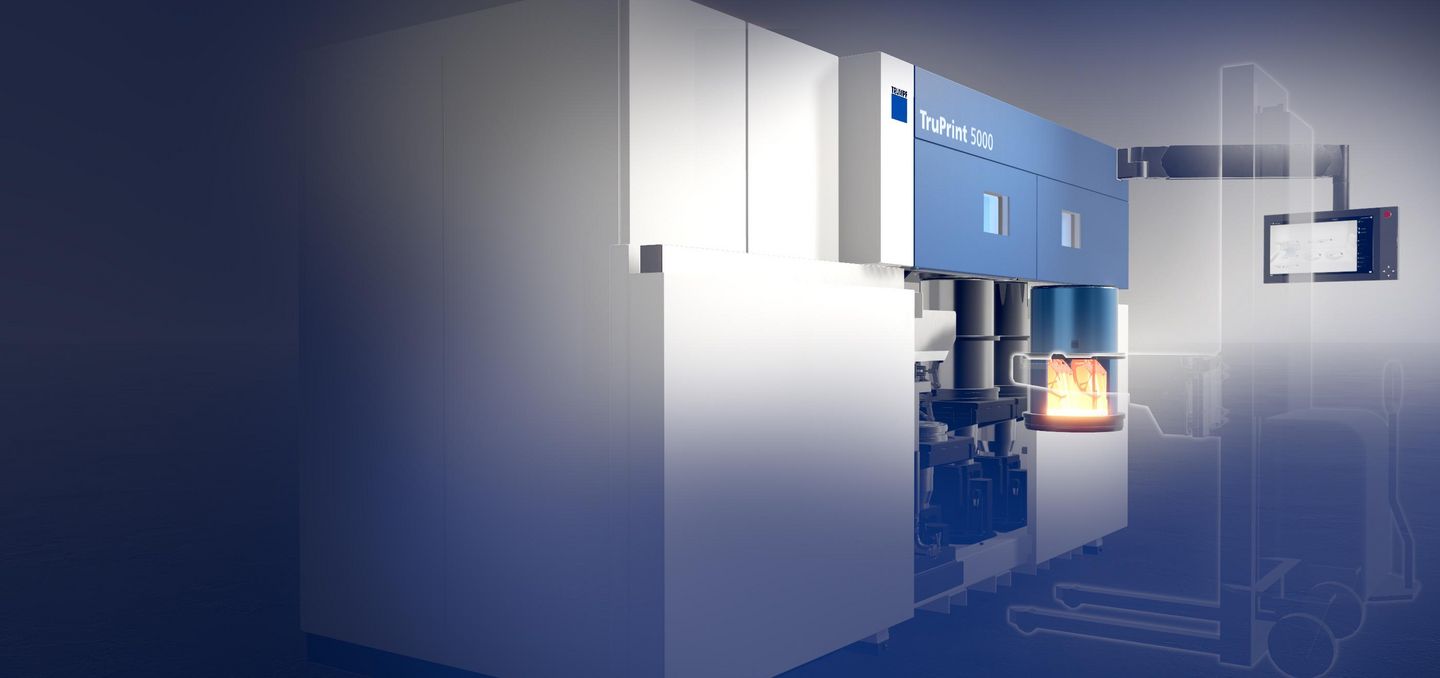

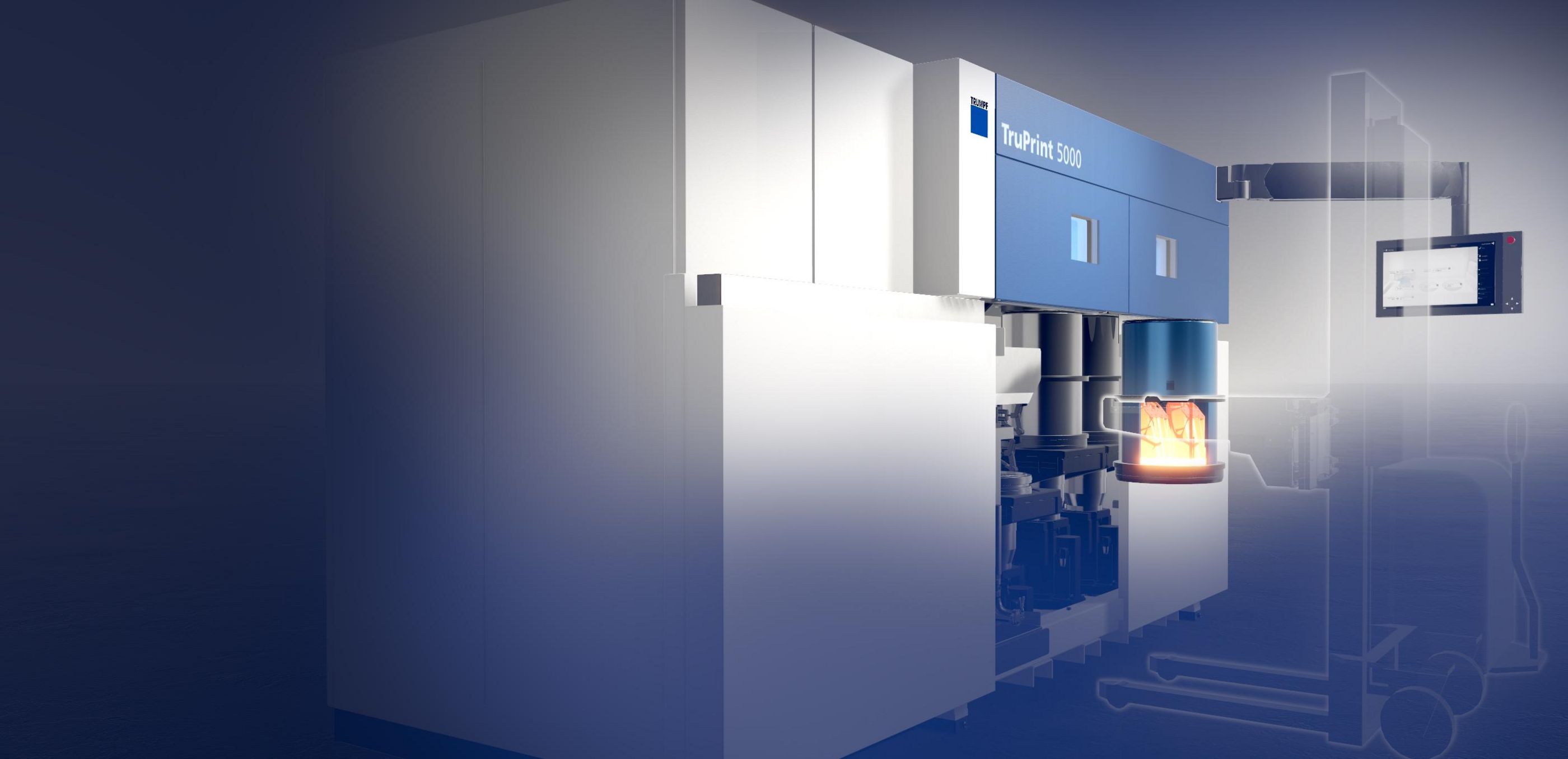

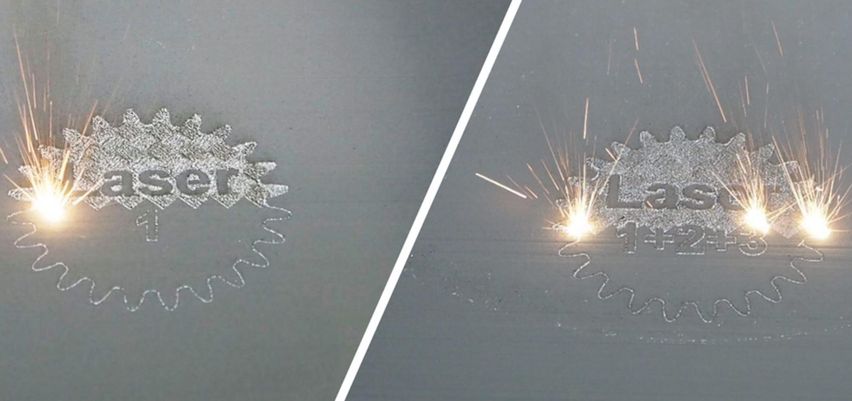

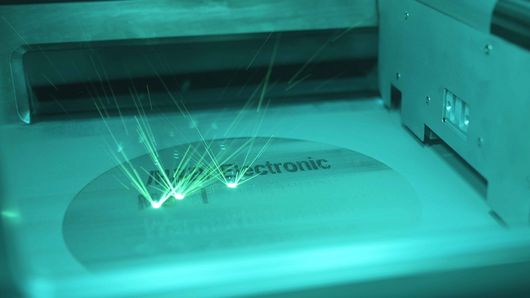

Thanks to the highly dynamic scan strategies with SCANahead, three 500 watt full-field multilasers simultaneously scan the entire build area and thus guarantee optimal surface quality without seams. In addition, with Automatic Multilaser Alignment, the positioning of the laser beam sources is automatically monitored and corrected if necessary, for reproducible component quality.

Create top-quality 3D components faster

The highly productive, partially automated TruPrint 5000 3D printing system provides the ideal basis for industrial series production. With optional features, including 500°C-preheating and the fullfield multilaser with three 500-watt TRUMPF fiber lasers, you are perfectly equipped to handle even the most demanding industrial applications. The machine quickly and reliably produces high-quality components made of different metallic materials – and in doing so meets the high quality requirements in tool and mold making, including by means of 3D printing on preform blanks, in aerospace and medical technology. As an option, the entire process chain can be carried out in a shielding gas atmosphere: sieving, printing, cooling, depowdering. Combined with external part and powder management and the monitoring solutions from TRUMPF, it is predestined for industrial additive series production.

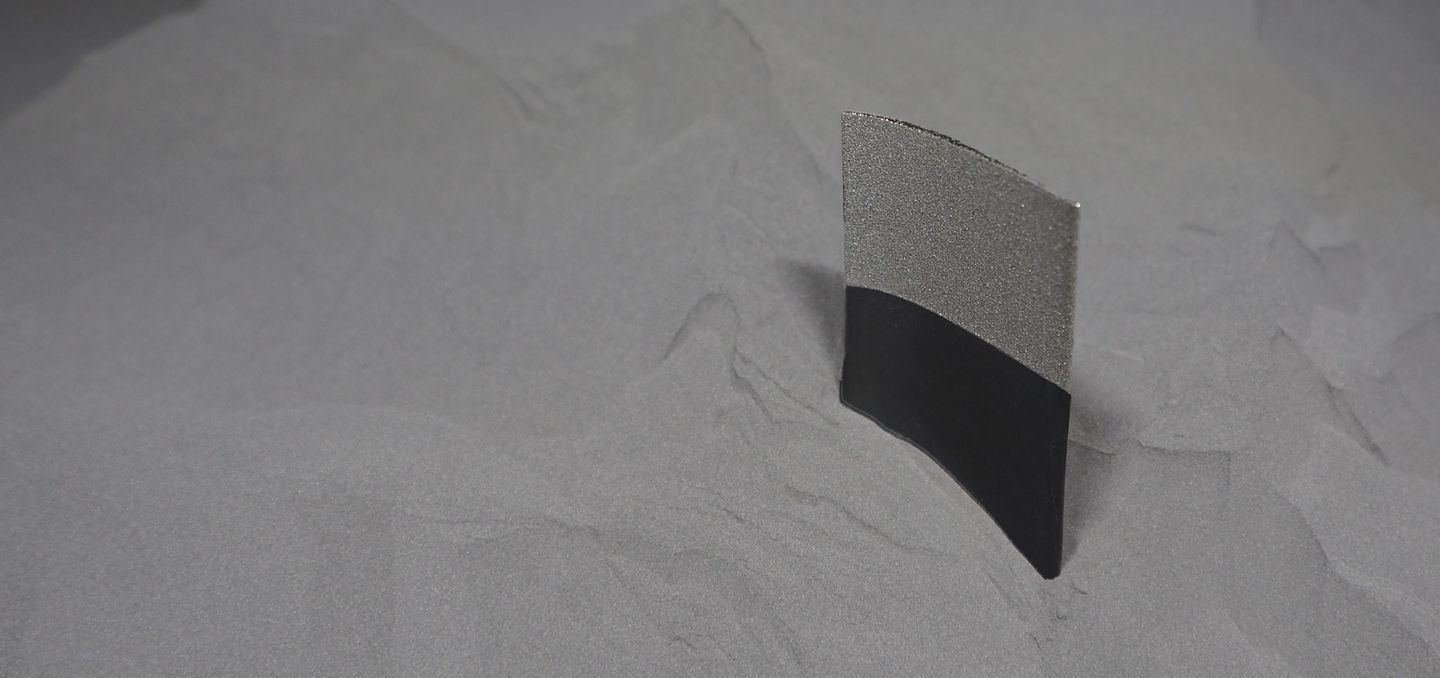

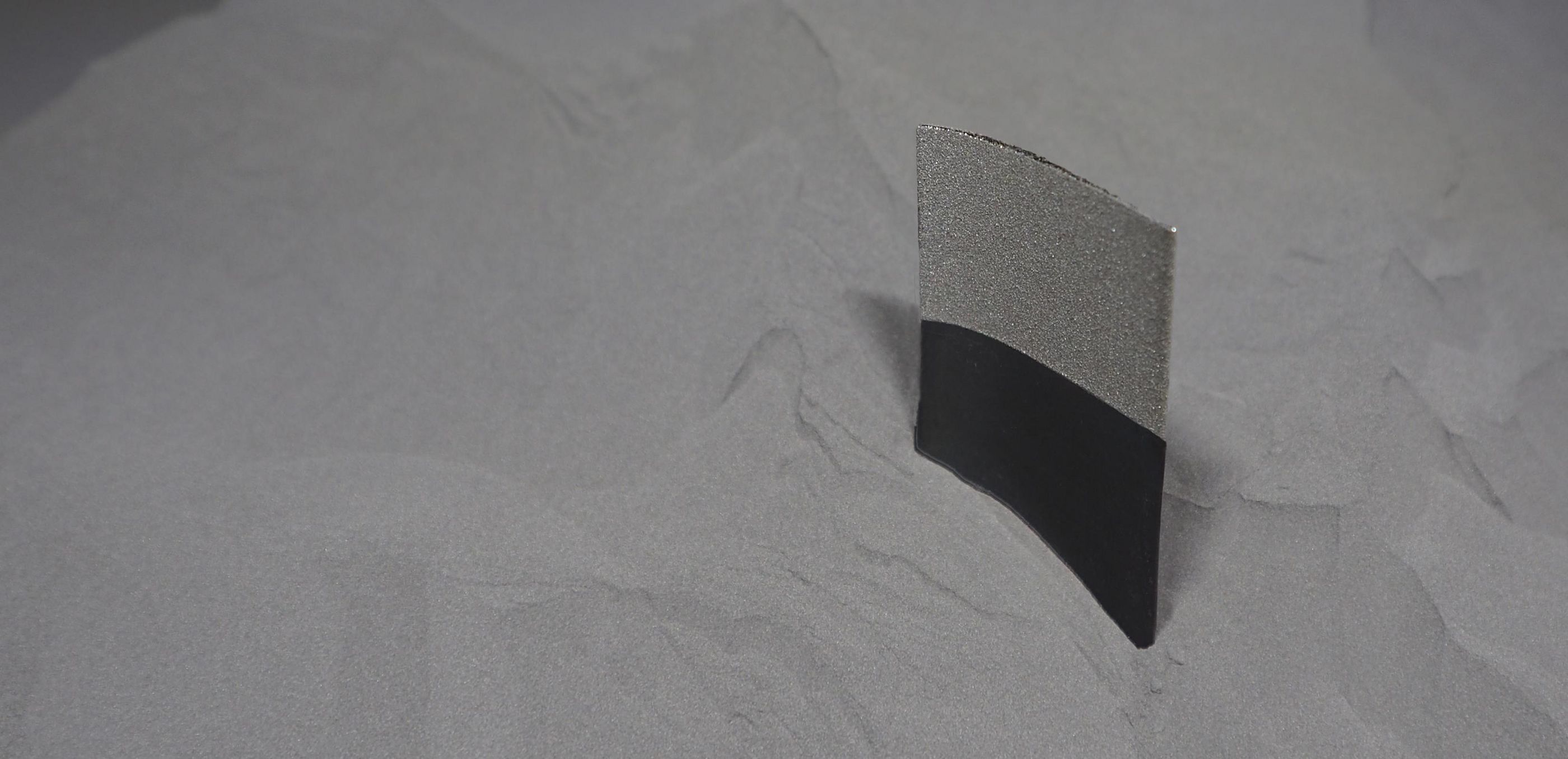

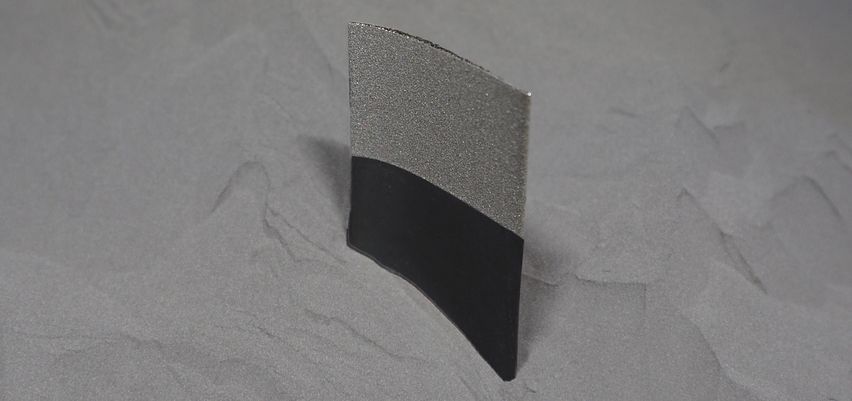

Thanks to the Preform option, the TruPrint 5000 supports hybrid component production. For this purpose, the component structures to be additively manufactured are applied to a blank. The innovative option is particularly well-suited for simple handling in tool and mold making.

Thanks to the highly dynamic scan strategies with SCANahead, three 500 watt full-field multilasers simultaneously scan the entire build area and thus guarantee optimal surface quality without seams. In addition, the positioning of the laser beam sources is automatically monitored and corrected if necessary.

Optional preheating of the substrate plate to up to 500°C ensures a high component quality and a robust LMF process. All important process steps can be performed under shielding gas.

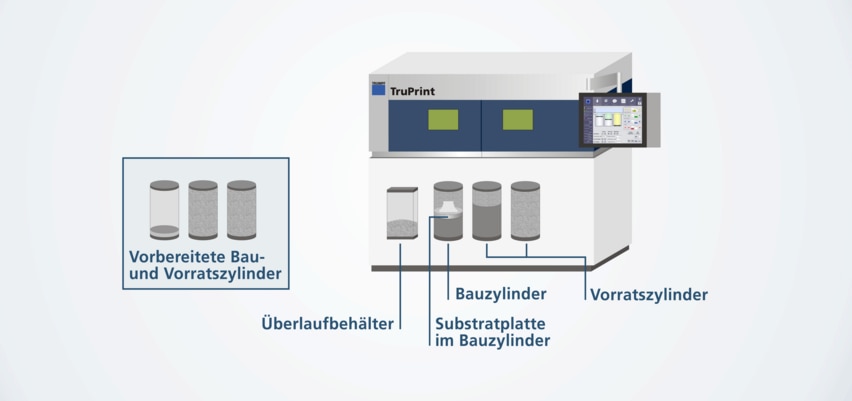

The automatic process start allows for fast set-up and offers a high degree of process reliability.

Thanks to the preform option, hybrid component production is supported. By using preform blanks you save time and money and at the same time enjoy the advantages of additive manufacturing.

The TruPrint 5000 enables you to work parallel to production: the set-up process is optimized, productivity is increased and contact with powder is avoided.

Keep an eye on the powder coating, weld pool, machine status, and productivity at all times and have full control over the component quality, layer-by-layer.

Heat exchanger

In the aerospace industry, metal 3D printers can produce large parts without cracks or delamination defects. With the TruPrint 5000 and the 500 °C preheating option, products such as the titanium heat exchanger (Ti64) can be printed in high quality and cost-efficiently – with no rejects or material waste.

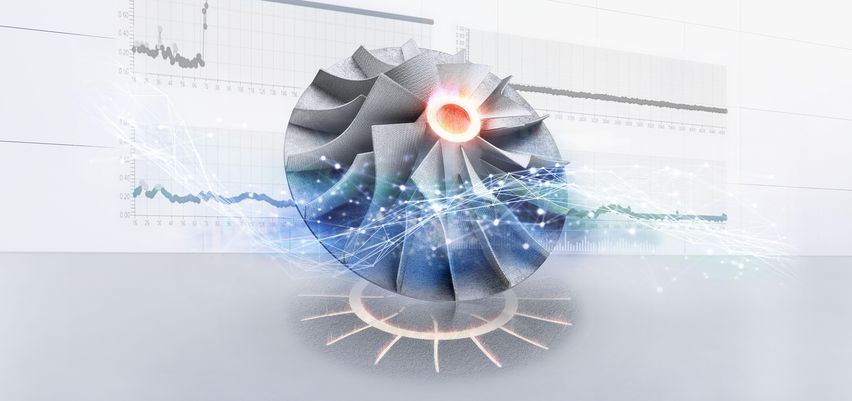

Injection nozzle ring

With the TruPrint 5000, high-performance materials can be processed with high productivity on an industrial production scale. The aerospace industry, energy sector and automotive manufacturing benefit from the new material Ti6242, which can be processed reliably and without internal stress in the component using the TruPrint 5000 at 500 °C, such as the injection nozzle ring from Blasius GERG GmbH.

Hybrid tool and mold-making with preform and 3D printing

Additive manufacturing allows you to create castings with deep ribs in a reliable manner. Cooling close to the contour effectively prevents the overheating of domed areas on sliders, enabling you to realize shorter cycle times. At the same time, this improves the micro-crystalline structure of the casting, which in turn increases its load capacity. Thanks to the Preform option, the TruPrint 5000 supports hybrid component production. For this purpose, the component structures to be additively manufactured are applied to a blank. Preform Basic is particularly well-suited for simple handling in tool and mold making.

Tool production using Preform and PBF

With the Preform option, the TruPrint 5000 can produce the milling tool in series, thereby saving costs and material by only printing where it is really necessary. Preform Advanced automatically enables high-precision positioning of the milling heads to be printed on the conventionally manufactured blanks. Design by Paul Horn GmbH.

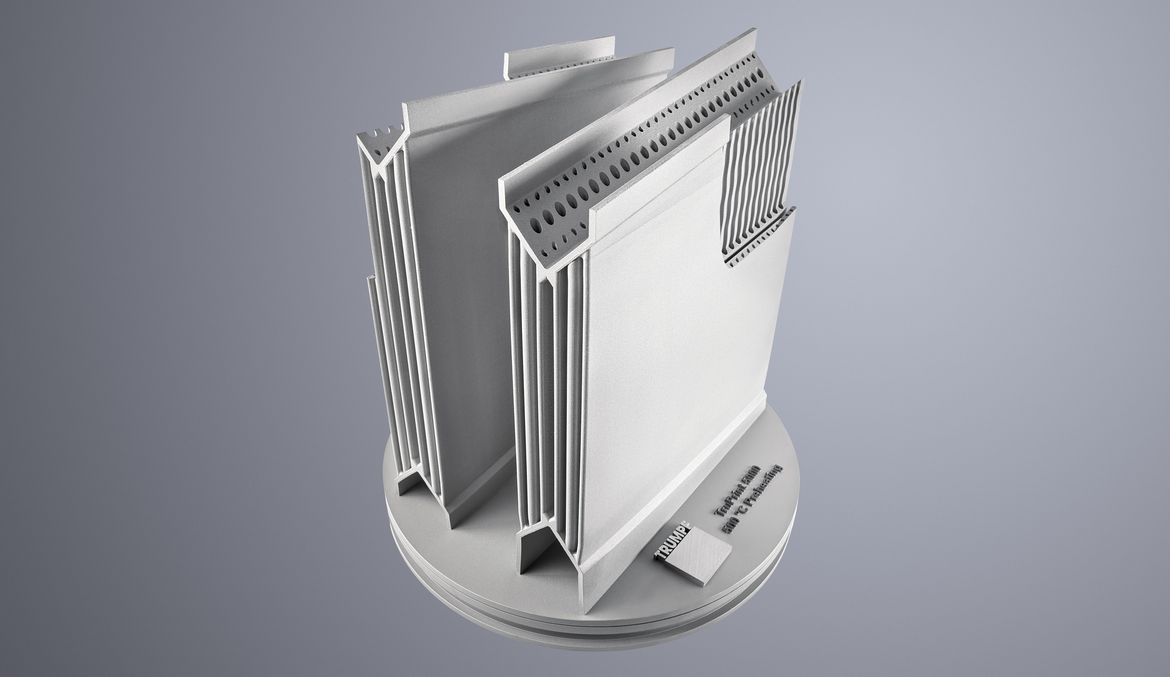

Bionically optimized heat exchanger

Computer-aided development of an efficient medium-sized heat exchanger by Hyperganic. The pressure drop was reduced by 50% compared to a conventional heat exchanger. The goal was to minimize the pressure loss while achieving maximum cooling capacity, which was only possible by using additive design. The heat exchanger was printed in Ti6242. Designed by Hyperganic.

Titanium hip socket Ti6Al4V ELI

The various grid designs on a hip socket were printed on the TruPrint machines with high detail resolution. Preheating to 500 °C can greatly reduce the amount of support structure; it is even possible to stack parts. Both steps have a positive effect on the entire process chain by reducing material costs and shortening the production cycle.

Bracket on the satellite

Unlike the conventional milling manufacturing process from a block with 95% material removal, by using additive manufacturing you can achieve a 28% reduction in the weight of the satellite structure, as well as a 45% increase in its rigidity.

Tool and mold making

With this Laupp GmbH runner optimized using Powder Bed Fusion, the process steps have been reduced from five to just one, and sealing points have been eliminated. Efficiency is increased and operating costs are reduced through the conformal tempering channels of the series component produced from titanium and the 500 °C preheating option.

Aviation and aerospace

Printing a gimbal with the 500°C preheating option significantly reduces residual stress in the Ti6AI4V component. This opens up entirely new possibilities in design, especially in the construction of more solid components.

Tool and mold making

Printed results for highly polished cores from Reinhard Bretthauer GmbH made out of H11 using the 500°C preheating option are crack-free with densities in excess of 99.9%. Polishing properties are also high with no difference to conventional production. Cooling performance is comparable to copper. Integrated cooling channels enable stable plastic parts production in injection molding and significantly reduces cycle times.

Turbine rotor blades for engines in aviation and aerospace

When a turbine blade is affected by wear, the decision often has to be made: discard it or repair it? Hybrid production with the Preform Basic option saves you costs, material and time for replacement. The defective part of the turbine blade is milled off; Powder Bed Fusion is used for 3D printing on the existing part. This is a significant advantage, especially when supply chains are strained.

|

TruPrint 5000

|

|

|---|---|

| Build volume (cylinder) | Diameter 300 mm x 400 mm Height |

| Effective build volume (when preheating > 200 °C) | Diameter 290 mm x 400 mm Height |

| Processable materials | Metal powders for welding, such as stainless steels, tool steels, and aluminum alloys, nickel-based alloys, titanium alloys. Current availability of materials and their parameters available on request. |

| Preheating (standard) | Up to 200 °C |

| Preheating (option) | Up to 500 °C |

| Maximum laser power at the workpiece (TRUMPF fiber laser) | 500 W |

| Beam diameter (standard) | 80 μm |

| Layer thickness | 30 - 150 μm |

| Build rate | 5 - 180 cm³/h 1 |

| Minimum measurable oxygen level | Up to 100 ppm |

| Connection and consumption | |

| Electrical connection (voltage) | 400 V |

| Electrical connection (current intensity) | 32 A |

| Electrical connection (frequency) | 50 Hz |

| Shielding gas | Nitrogen, argon |

| Structural design | |

| Weight (including filter, electrical cabinet, powder) | 7085 kg |

| Dimensions (including filter, electrical cabinet) (W x H x D) | 4616 mm x 1645 mm x 2038 mm |

| Dimensions (including filter, electrical cabinet) (W x D x H) with 500 °C preheating option | 5266 mm x 1645 mm x 2038 mm |

The technical data of all product versions as a download.

TruTops Print

TRUMPF provides the suitable software solution with TruTops Print so you can get the best out of the TruPrint machines. The modern user interface summarizes all functionalities in a clear overview and facilitates quick access to all functions. Maximum efficiency and productivity with optimum printing quality, reproducibility and support-reduced overhang construction are ensured thanks to the high degree of flexibility and the individual options for data preparation, such as z-segmentation, as well as the intuitive and clearly arranged parameter management with fully accessible parameters. The high quality of the generated vector data in the WZA file format can be verified with the integrated BuildJob Viewer.

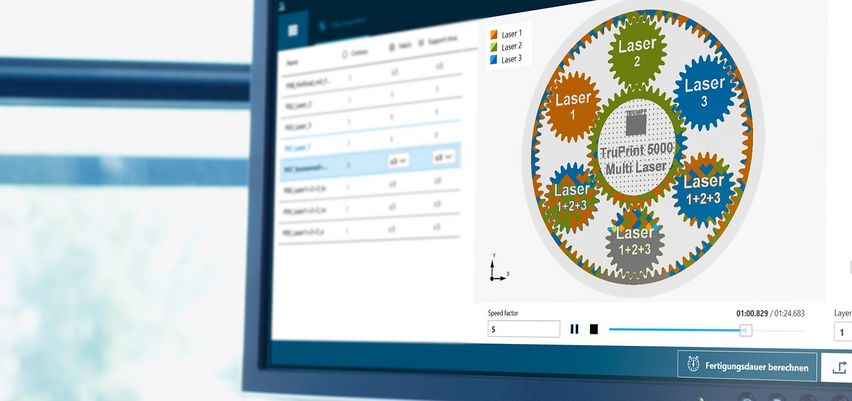

TruTops Print Multilaser Assistant

Intelligent and flexible control options are needed in order to make optimal use of the three TruPrint 5000 fullfield multilasers. These options are provided by the Multilaser Assistant integrated in TruTops Print, in which laser allocation is configured, in order to optimize the build job in terms of productivity and quality. Additionally, the processing sequence can be viewed, and production time can be predicted.

Data preparation suitable for your workflow

TruTops Print is already connected with numerous CAD/CAM systems for a seamless data preparation workflow. This offers you the greatest possible flexibility when selecting the data preparation software. Decide for yourself which solution suits your workflow perfectly.

With four different profile sides available for use, you can achieve a perfect, uniform powder coating and benefit from the highly durable recoater component X profile, as well as a robust process.

Note: This option is compatible with preheating up to 200°C.

The heat-resistant carbon fiber brush enables a faster and more robust powder coating, especially with preheated temperatures from 200°C.

A high component quality is achieved through optionally preheating the substrate plate to up to 500°C. This enables a robust LMF process for a wide range of materials, ideal for sectors that place high demands on their applications (preheating basic machine of up to 200 °C). The industrial exchangeable cylinder principle in combination with the cooling station make it possible to cool down the hot build job parallel to production. This increases the productivity of your 3D printer.

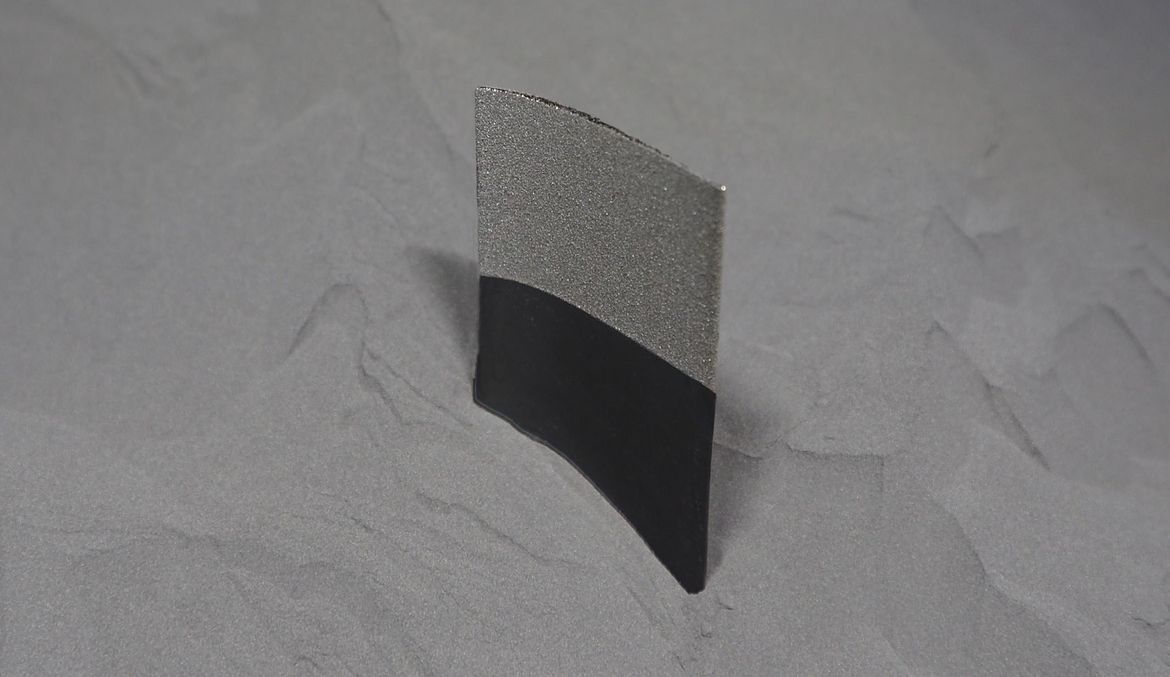

With the Preform Basic option, you only print at the point where it is really necessary for the component. In addition to printing time, this also saves machine and powder costs and supports sustainable hybrid production as well as the reprocessing of defective components.

Use the Preform Advanced option for an automatic and sensor-based solution via markers. In this way, you can achieve reproducible and highly accurate results in series production.

You can automatically monitor the powder bed via an integrated camera in the TruPrint component chamber and the automatic image processing function. This means that you have a constant overview of the state of the component and can analyze the quality parameters layer-by-layer. A lack of powder is detected by the automatic corrective recoating option and the affected layer is automatically corrected by a new powder coating.

Deviations in the laser metal fusion process can be detected early on via sensors, and critical areas of the component can be seen. All weld pools from the three full-field multilaser can be monitored in parallel.

The Laser Power Measurement option is available for your TruPrint 5000. Check the laser power at any time, thereby ensuring an optimal process. In doing so, you also fulfill potential obligations to provide evidence.

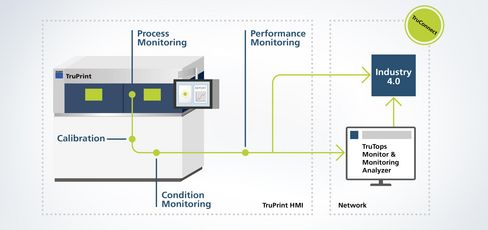

TruPrint monitoring

Using TRUMPF's intelligent monitoring solutions, you can monitor, analyze and calibrate the LFM process of the TruPrint machines with ease. You can then produce even more efficiently and achieve higher component quality. The professional monitoring process makes it possible to display and analyze sensor-based data. The offer comprises solutions for monitoring the process, condition, and performance. The monitoring results can be seen directly on the HMI of the TruPrint machine or can be analyzed offline via the Monitoring Analyzer. With TruTops Monitor, you get full transparency along with the option to have remote access via a PC or tablet. Furthermore, the OPC UA interface provides full flexibility to connect to your own software solution. With the additionally available calibration functions, you can check the process-relevant parameters for optimal production conditions before the start of the build job.

Optimal handling of the powder and components is crucial for series production on an industrial scale. The industrial parts and powder management from TRUMPF enables the setup and powder removal of one or more machines, all parallel to production. This increases productivity and profitability for our customers. Standard interfaces and a modular structure guarantee maximum flexibility.

Powders and parameters

High-quality metal powders are the basis for reliable process conditions in additive manufacturing. The combination of recommended powders and the correct parameters creates high-quality material properties for 3D-printed components.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

Footnotes-

The actual build rate consisting of exposure and coating. Dependent on the configuration of the system, the process parameters, material and fill level.