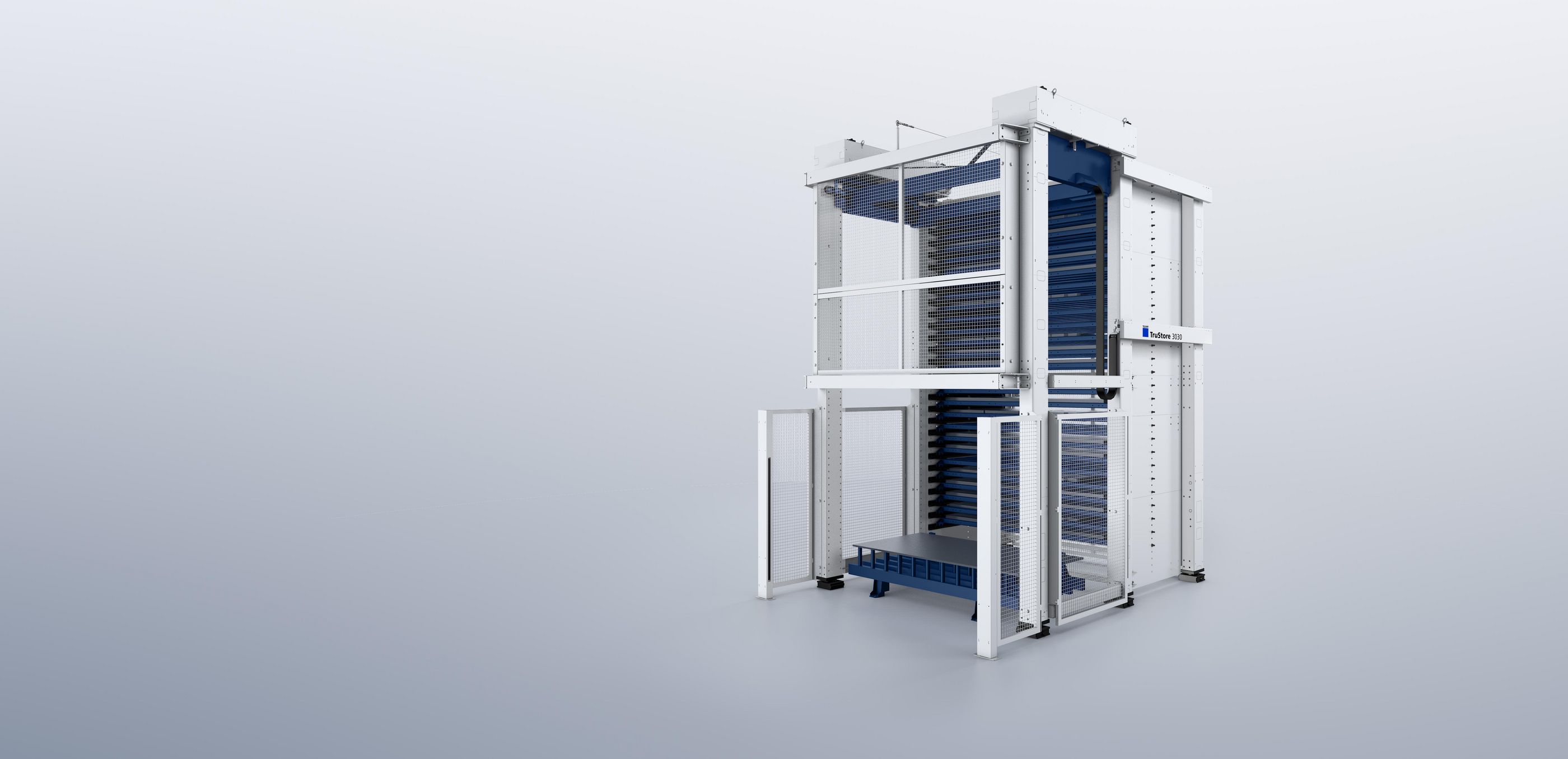

The dynamic compact storage system

The TruStore Series 3000 compact store grows along with your demands, reduces space requirements, and can be developed into a fully automatic system. The TruStore Series 3000 comes with a storage tower and pallet picker crane as standard. You can select the height of your store from 15 possible levels, and the storage compartments can be adjusted to 90, 170, or 260 mm. You can choose 2 loading heights in one system. The storage system can be easily connected to your TRUMPF 2D laser cutting machine, punching machine, or punch laser machine. The modular principle enables expansion at any time.

Increase your machine utilization rate by 100% – with an unmanned shift.

The TruStore Series 3000 enables floor space savings of up to 85%.

With the modular principle, it is possible to convert or expand at any time

Store up to 245 tons in large format.

Software

The software portfolio from TRUMPF optimizes your entire production process – from the customer query to delivery of the finished part. TRUMPF combines the software intelligently with machines and services to create customized Industry 4.0 solutions for your Smart Factory.

With additional equipment options, you can increase the capacity of the TruStore Series 3000.

Space-saving storage of auxiliary pallets with storage cassettes

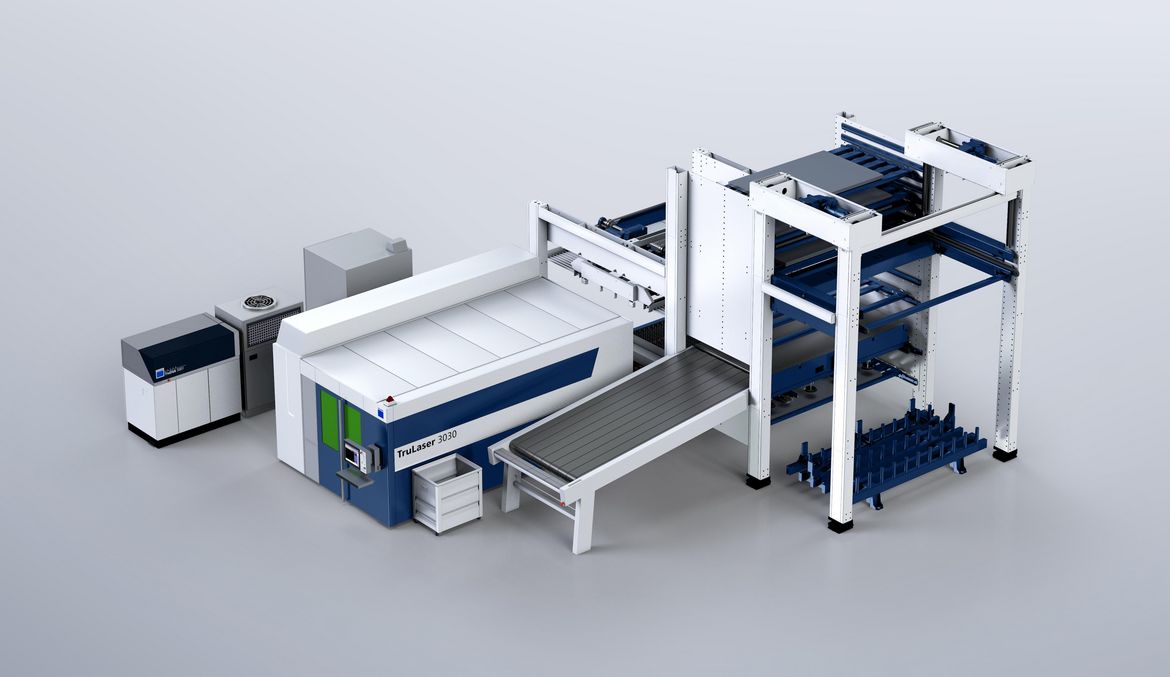

Connection of a TruLaser 3030 fiber laser machine to the TruStore system with LiftMaster Compact and PartMaster

You can connect multiple machines to the TruStore as required, either directly or indirectly

Precise, to-the-second recording of stock: The weighing system weighs the sheet stack on the pallet picker crane.

Direct connection of a TruLaser 3030 fiber laser machine to the TruStore system, also with LiftMaster Compact and PartMaster.

You can connect multiple machines to the TruStore as required, for example two TruLaser 3030 systems with a LiftMaster Store.

TruStore 3030 connected to a TruMatic 7000 with SheetMaster, dual loading carts on rails, SortMaster Pallet, SortMaster Box, GripMaster, and ToolMaster

TruStore 3030 connected to a TruLaser 5030 with LiftMaster Store and SortMaster

TruStore 3030 connected to a TruLaser 3030 with LiftMaster

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.