Headquartered in the Japanese town of Ōguchi, Okuma is one of the world’s leading CNC machine tool manufacturers. But what’s different about this company is that it specializes in multitasking machines that combine several production methods in a single unit – turning, milling and grinding for instance. These are all subtractive production methods and, at the time of the phone call, the machines only offered this type of functionality. “But what if we incorporated an additive method, too?” Yamamoto continues. “That would give us the best multitasking machine anyone has ever seen.”

Partner should have experience with additive technologies

Yamamoto emphasizes that Okuma wasn’t looking to reinvent the wheel: “We wanted to work with a partner that had experience in additive technology and was prepared to pair their expertise with our tried-and-true machine components and the control system we have developed here in house.” The quality expectations were high and Yamamoto was keen to get things moving quickly, without spending too much time on long test periods. “After my phone call with Antonio Candel-Ruiz at TRUMPF, I knew we’d found our perfect partner.”

When choosing a laser, TRUMPF's sensitivity is required

TRUMPF’s coating expert Antonio Candel-Ruiz set to work. “It was an exciting but somewhat daunting prospect. Machining processes are really fast, so we weren’t sure if adding LMD to the mix was even feasible. And how would we cater to Okuma’s broad set of requirements? They wanted a full range of deposition coverage, from wafer-thin structures to larger surfaces – and the quality had to be second to none. Then, on top of all that, there was laser hardening to consider! That effectively narrowed down the options to just one type of laser: the disk laser,” he says. In the end, Candel-Ruiz opted for a relatively powerful four-kilowatt disk laser with extremely high beam quality. Delivering twice the required performance, it more than exceeded Okuma’s expectations. They had cleared the first hurdle. “The next step was the optics,” Candel-Ruiz continues. “Flexibility was a key factor here, too, because Okuma understandably wanted to avoid having to change the optical system.” Fortunately Candel-Ruiz had the right answer up his sleeve. He chose an optical system with a variable laser spot diameter that can be adjusted between 0.4 and 8.5 millimeters.

Quick course in additive manufacturing: Laser Metal Deposition

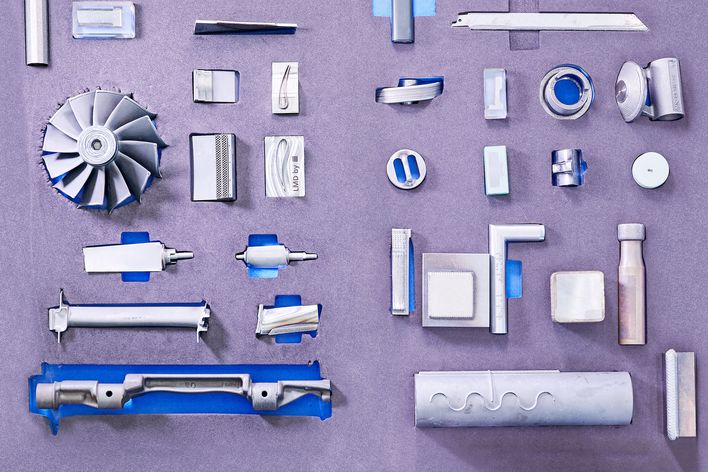

Yamamoto recounts his side of the story: “LMD was unchartered territory for us, which is why we were delighted to find laser equipment so well matched to our requirements. The expertise in additive manufacturing that TRUMPF brought to the table was equally as important. Together, we managed to build up a huge knowledge base in a very short space of time.” The first step was for the experts from both companies to sit together, look at Okuma’s portfolio and determine which parts would lend themselves well to LMD processing. Candel-Ruiz recalls their collaboration from his perspective: “Okuma built several prototype machines for which we developed sample applications there on site. Our focus was on identifying suitable materials and the most favorable geometries. Know-how transfer was key. For example, we showed them how parameters such as laser power and gas quantity depend on which powder you’re using, and explained how to develop suitable exposure strategies.”

Machine concept enables additive and subtractive technologies

All the hard work has paid off and Okuma has now rolled out the enhanced multitasking concept to two new machines. They perform milling, turning, grinding and laser metal deposition and can also be used for heat treating workpieces of all different shapes and sizes. Yamamoto is over the moon with the results: “Using the machine for hardening is much faster and results in less deformation. And eliminating the need for post-processing has really paid off. Throughput times are reduced by 90 percent, enabling our customers to increase their output rates tenfold.”Design engineers are increasingly aware of the advantages that hybrid manufacturing methods offer and are factoring the technology into their production plans from the outset. “We supply the right machines for the job,” he says. “I reckon we’ll soon be seeing parts that are specifically designed to be produced or processed on multitasking machines only.”