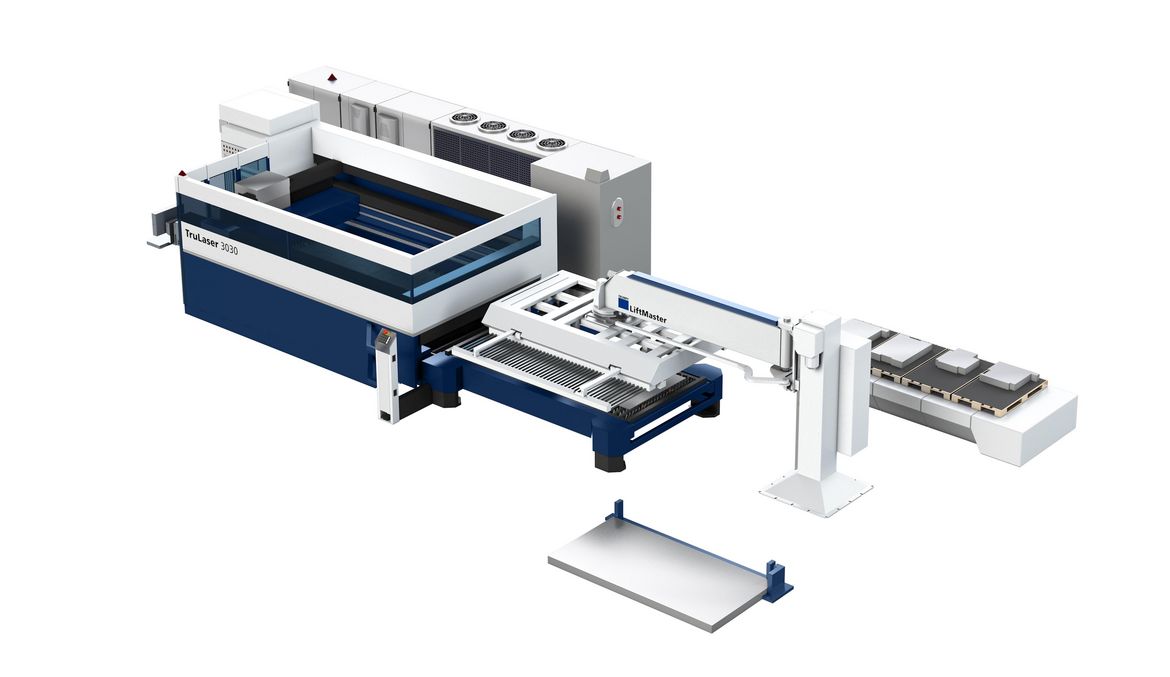

Flexible automation

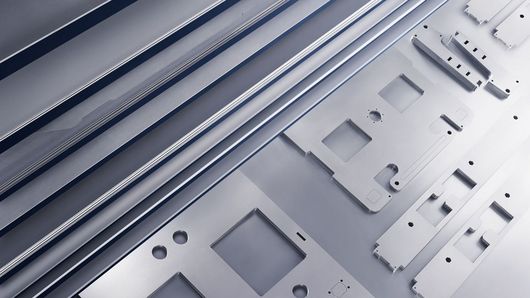

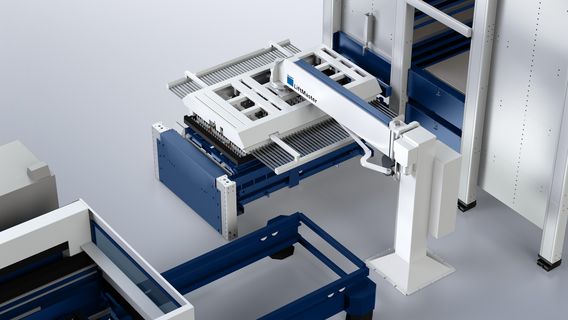

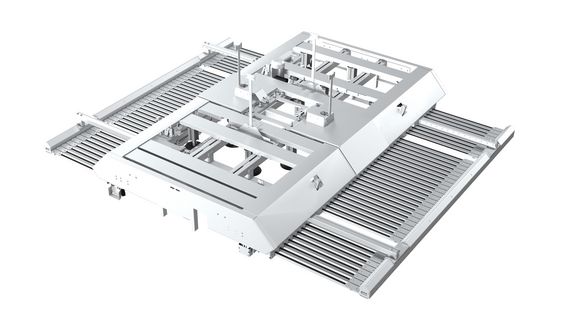

The automation solution, LiftMaster, covers a broad range of functions because of the variety of setup options. These range from simple loading and unloading processes to pallet handling and part removal. The basic module is the suction frame. It contains both suction cups, for the transportation of the unprocessed sheet, and rake arms for conveying cut sheets. With the integrated sorting function, the LiftMaster can also separate finished parts from the scrap skeleton and set them down.

The LiftMaster offers low-scratch part handling.

The swivel arm of the LiftMaster automatically adjusts to the circumstances of your application.

Even without supervision, the LiftMaster will run 24/7 without compromising process reliability.

For a complete loading and unloading cycle, including pallet change, the LiftMaster requires just four minutes.

|

LiftMaster large format

|

LiftMaster max format

|

|

|---|---|---|

| Loading | ||

| Maximum sheet size | 3000 mm x 1500 mm | 4000 mm x 2000 mm |

| Minimum sheet size | 1000 mm x 1000 mm | 1000 mm x 1000 mm |

| Maximum sheet thickness | 25 mm | 25 mm |

| Maximum sheet weight | 900 kg | 1600 kg |

| Unloading | ||

| Maximum sheet size | 3000 mm x 1500 mm | 4000 mm x 2000 mm |

| Minimum sheet size | 150 mm x 150 mm | 150 mm x 150 mm |

| Maximum sheet thickness | 25 mm | 20 mm |

| Maximum sheet weight | 900 kg | 1260 kg |

| Minimum part size | 150 mm x 150 mm | 150 mm x 150 mm |

The technical data of all product versions as a download.

Introduction to the LiftMaster storage connection

With the LiftMaster Sort you can separate large parts from the scrap skeleton.

So-called belt prongs enable low-scratch part unloading with high positioning accuracy

Auxiliary pallets assist the loading and unloading process. The LiftMaster automatically takes care of their handling.

The unloading rake takes the finished, processed sheet from the pallet changer and places it in the unloading area. The suction frame is fitted with individually controllable suction cups that pick up the unprocessed sheets from the loading area and place them on the pallet changer

With the thin sheet separation option, you can even separate film-coated or oily sheets with a thickness between 0.03 and 0.08 inches.

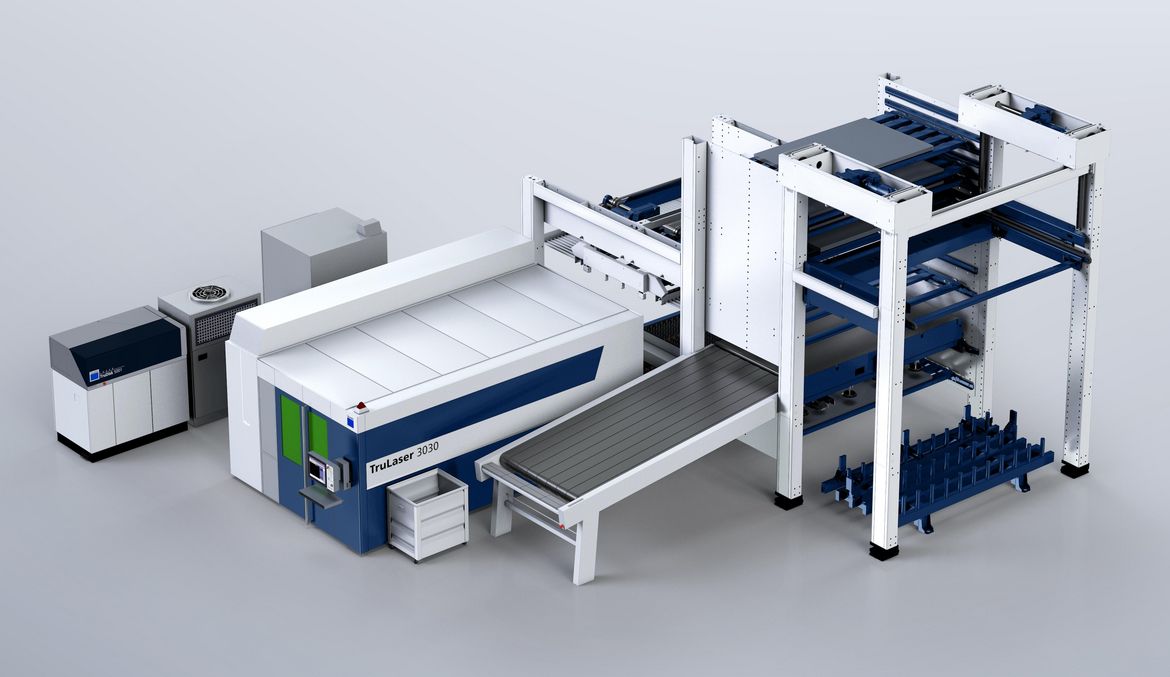

TruLaser 3030 with LiftMaster, PartMaster, and TruStore 3030

The LiftMaster connects a TruLaser 3030 indirectly with a TruStore 3030

TruLaser 3030 with LiftMaster

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.