TruLaser Cell 8030 hot-forming machine up to 20 percent more productive thanks to extensive improvements – unique “x-blast technology” lowers nozzle collisions and machine downtimes – more dynamic drives reduce part costs

TRUMPF gives automotive industry significant productivity boost in 3D cutting

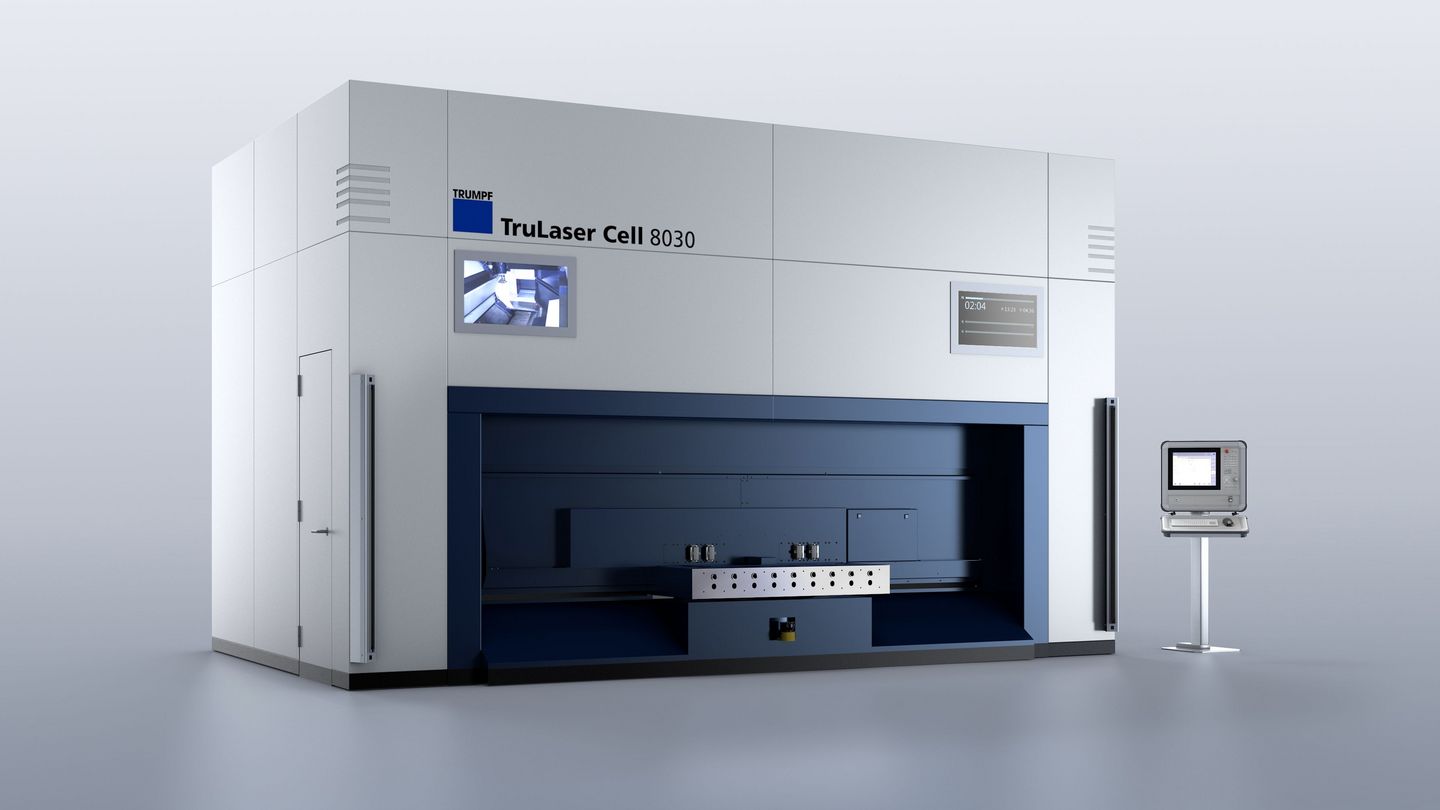

Hanover / Ditzingen, October 25, 2016 – Laser system manufacturer TRUMPF has completed a major revamp of the second generation of its TruLaser Cell 8030 hot-forming machine. At the Euroblech trade exhibition in Hannover, the company is demonstrating new functions that can increase the productivity of the machine by up to 20 percent. The focus is also on so-called x-blast technology, which greatly reduces machine downtimes and collisions between cutting nozzle and workpiece. The main field of application for the re-engineered TruLaser Cell 8030 continues to be the laser cutting of hot-formed 3D components, a technology that is primarily used in the automotive industry.

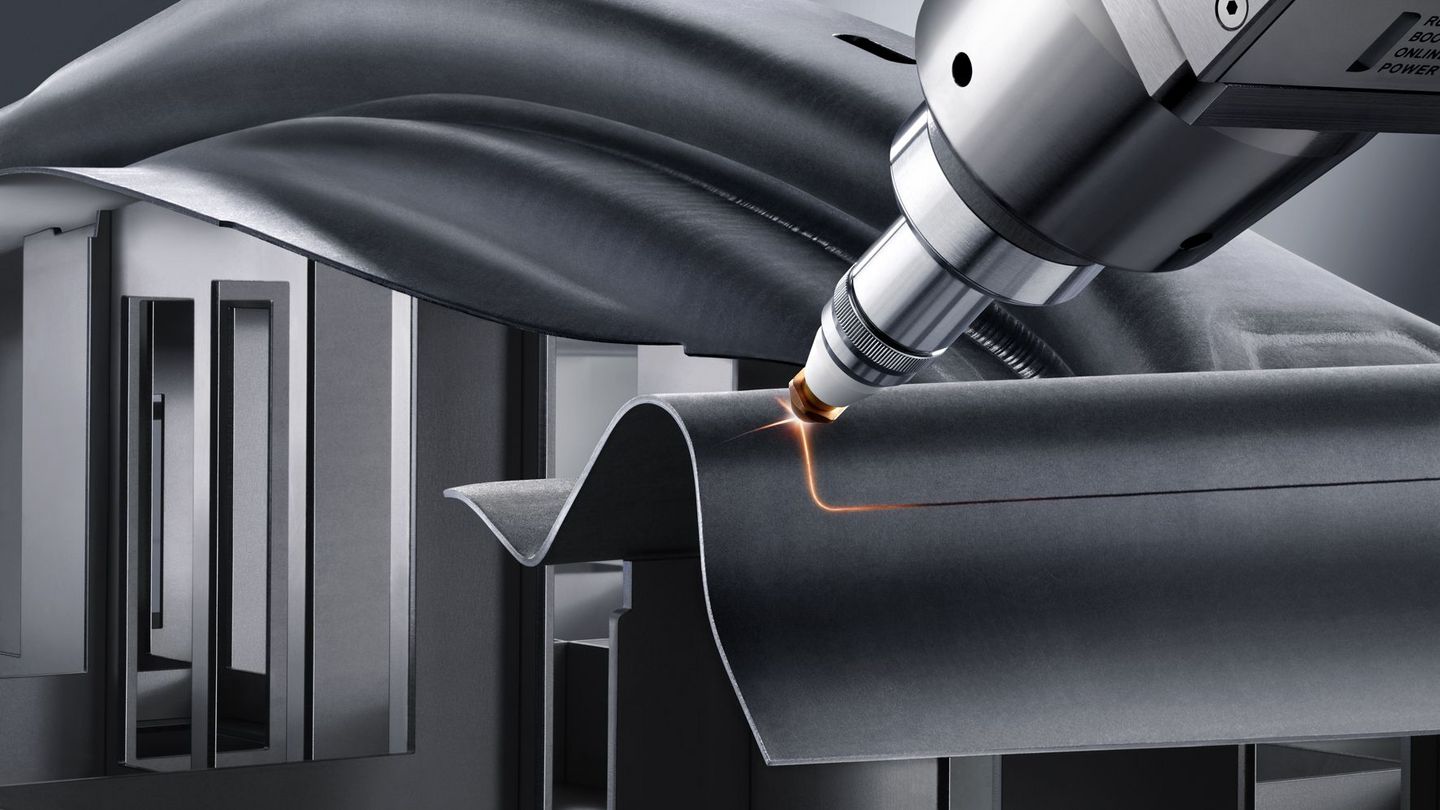

Fewer collisions thanks to larger nozzle stand-off

With its innovative x-blast technology, TRUMPF has pulled off an impressive coup: previously, to achieve good cut quality, the cutting nozzle fitted to the processing optics had to operate as closely as possible to the workpiece. However, the closer the nozzle gets to the workpiece, the higher the risk of them making contact during the cutting process. And because the machine stops after every contact, this can seriously reduce the productivity of the machine.

The new x-blast technology allows operators to almost double the working distance between nozzle and workpiece. This greatly reduces the number of nozzle contacts with the component, which in turn leads to far fewer machine downtimes and higher productivity. Because fewer contacts occur with the x-blast technology, the service lives of cutting nozzles are also increased by a factor of ten. Or to put it another way: customers are faced with only 20 percent of the original costs of cutting nozzles.

Another advantage of the new technology is that it doubles the process bandwidth. Even with critical 3D geometries, when the laser has to work under difficult process conditions, the TruLaser Cell 8030 can now cut components quickly and in very high quality thanks to x-blast technology. With the proportion of automated machines in production growing all the time, the advantages of x-blast technology form the ideal basis for stable and reproducible component quality.

New functions for greater convenience

TRUMPF has also expanded its optical slug detection feature for quality control. ObserveLine Comfort reliably detects cutting slugs, increasing production dependability. When the operator causes collisions with chucks or components, it can affect the accuracy of the machine. With the new ObserveLine Professional feature, this accuracy can be ensured by means of a variably adjustable testing interval. For example, if a customer wants to inspect their machine after every hundredth component, this can be accomplished – when the time is apportioned to the individual component – in just 0.02 seconds. Accordingly, ObserveLine Professional is effectively time-neutral and causes no appreciable delay in production.

Another new feature is SmartApproach, which offers improvements especially when partially cutting workpieces. SmartApproach quickly and precisely calculates the actual height of the component edge; the laser ignites the beam even before it is positioned over the workpiece and then swiftly executes the cutting contour. SmartApproach increases the productivity of the machine by up to nine percent. The additional dynamism of the drives yields a further eleven percent. TRUMPF adjusted and optimized the mechanical drive components at decisive places, with the result that the drives reach maximum acceleration much faster than before. In total, the productivity of the TruLaser Cell 8030 has increased by up to 20 percent when 3D cutting hot-formed components.

Customers can freely choose which laser to use for 3D cutting according to the requirements of their business and of the specific applications. TruLaser Cell 8030 is available with the tried-and-tested TRUMPF disk lasers TruDisk 2000, TruDisk 3001, and TruDisk 4001 with two, three, or four kilowatts of laser power respectively.

Digital photographs in print-ready resolution are available to illustrate this press release. They may only be used for editorial purposes. Use is free of charge when credit is given as “Photo: TRUMPF”.