The top model is the first TRUMPF laser marking system with a stable construction that is ideal for industrial use featuring a polymer concrete plate as the main design component. In addition, you can find all additional advantages of the TRUMPF laser marking work stations in the TruMark Station 7000 as well: this includes the laser supply unit integrated in the machine frame, as well as the integrated rotary axis for circumference marking in addition to other features. The system's functions can be monitored using Remote Services. After activation, our service experts can provide additional help quickly.

Large scale in series production

With its generous inside dimensions, the TruMark Station 7000 laser marking system provides plenty of space for almost any application. It doesn't matter if you want to mark a single large component, or components weighing up to 75 kg with laser precision, or a large number of small parts in a series. An additional option for the TruMark Station 7000 is our rotary table system which assists with parallel-to-production loading and clearly boosts productivity. It is perfectly suited for heavy components and fixtures up to approx. 77 lbs per side. The entire work area has excellent accessibility and the outstanding ergonomics make it easy to work with. The motorized door provides safety and boosts productivity by opening and closing quickly. There is also an option to partially open or close the door. The fast-moving axes keep non-productive time to a minimum. Selective smoke and particle extraction systems perfectly tailored to our TruMark lasers ensure an emission-free work environment, even when using high laser power. In addition, the torsion-resistant system ensures excellent vibration damping even for heavy components through a polymer concrete plate as a central component.

The large work area and many options mean that the station is ideal for large batch sizes – especially with the rotary table.

The well-thought-out design of the work station counteracts operator fatigue.

One user interface for operating the axes, laser parameters, and external communication

The laser power on the workpiece remains entirely unaffected due to the precise spot extraction system. This allows the quality of the marking to remain consistent.

For every application, various TRUMPF beam sources, pulse durations, and power classes can be combined with the station with flexibility. This allows for perfect application results.

The combination of vibration dampening polymer concrete plate and rotary table unit allow heavy components to be loaded and processed at the same time, without affecting the marking parallel to the cycle time.

Color change

Washing machine panels made of plastic can be easily and quickly marked with a UV marking laser, due to the large work area of the TruMark Station 7000. This results in dark, high-contrast scales, type and brand designations on the light panel, which are also pleasantly smooth to the touch as the plastic is not foamed.

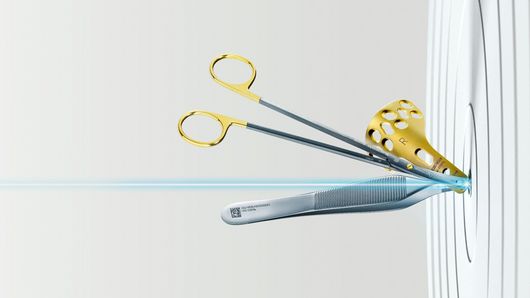

Precise marking of intricate medical products

The TruMark Station 7000 marks even very intricate products in medical technology – which often have a curved surface – to a consistently high quality. For example, the neurosurgical implants shown above.

Annealing

Localized heat input is used to discolor the workpiece surface. The annealing color changes depending on the material and the energy input. The surface stays smooth, which means that dirt cannot be deposited.

Engraving

During engraving, the laser beam removes part of the base material, thus creating a depression. This may have steep or beveled edges.

Discoloration

If the material and laser wavelength are optimally matched, the dye molecules are deliberately discolored or faded. The surface remains smooth. In addition to metallic materials, organic substances such as wood or leather can also be processed with the TRUMPF marking lasers.

Surface processing

The laser can be used to structure surfaces for a specific function or to clean them. This way, rust, oil, or phosphate layers may be removed in preparation for subsequent processes, such as laser welding.

Structured surfaces

The laser can be used to structure surfaces for a specific function. If the surface is structured with tiny melt elevations, significantly higher adhesion effects can be achieved with the same material properties. If interlocking components are structured through the addition of micro-depressions, the running characteristics improve significantly with the same quantity of lubricant.

Ablation

Ablation partially removes thin top layers of multi-layer plastics which are applied to the basic material and have very different colors. This process can be used for the day and night design, for example, which is used in the automotive and other industries.

Foaming

During foaming, the laser heats the plastic to cause a short melting process. During the subsequent cooling process, small gas bubbles become trapped and diffuse the light that falls on them and is reflected. This type of laser marking produces a raised marking.

|

TruMark Station 7000

|

TruMark Station 7000 with rotary changer

|

|

|---|---|---|

| Workpiece specification | ||

| Maximum workpiece dimensions without Y axis (W x H x D) | 1000 mm x 450* mm x 650 mm * Depending on laser and optics | - |

| Maximum workpiece dimensions with Y axis (W x H x D) | 960 mm x 450* mm x 375 mm * Depending on laser and optics | - |

| Diameter of rotary plate | - | 770 mm |

| Maximum workpiece weight | - | 35 kg per page |

| Maximum workpiece weight (without Y axis) | 100 kg | - |

| Maximum workpiece weight (with Y axis) | 50 kg | - |

| Available motorized axis | ||

| Traverse path of the Z axis | 500 mm | 500 mm |

| Traverse path of the X axis | 650 mm | 650 mm |

| Traverse path of the Y axis | 350 mm (not available for rotary table) | - |

| Z traverse speed | 6 m/min (2.7 m/min for TruMicro Mark) | 6 m/min |

| X traverse speed | 6 m/min | 6 m/min |

| Y traverse speed | 6 m/min | - |

| Dimensions and weight of work station | ||

| Dimensions of work station (W x H x D) | 1150 mm x 2000 mm x 1410* mm * for rotary table version 1625 mm | 1150 mm x 2000 / 2525 mm x 1625 mm |

The technical data of all product versions as a download.

TruTops Mark

The TruTops Mark marking software makes marking with the TruMark lasers as easy as possible. The TruTops Mark program combines the marking software, CAD editor, management of laser parameters and interfaces, sequence programming with QuickFlow, and a diagnostics tool. An intuitive interface puts all the functions at your fingertips. You can easily draw and arrange graphic objects with the CAD editor. The database for laser parameters enables you to re-use optimized parameters many times over. You can use the QuickFlow sequence programming to create "drag and drop" programs that control the complete marking cycle from beginning to end. The diagnostics tool visualizes and analyzes the analog measured values recorded by its sensors.

TruTops Mark 3D

Our TruTops Mark 3D marking software is ideal due to its user-friendly operation and significantly shorter process times. From now on, depending on the application, multiple objects to be marked can be reached with a laser system – especially where multiple lasers would have been required in the past. This makes the marking of three-dimensional surfaces such as sloping or curved surfaces very easy and efficient. In addition to the marking software, the package also includes a comprehensive 3D CAD editor, which can be used to independently create workpieces, and from which drawings for 3D marking can created.

TruTops Mark Module Interface

With the TruTops Mark Module Interface (TTM-MI), you can customize the content, appearance, and layout of the TruTops Mark user interface, entirely based on your needs. Operation is then tailored to your entire production and process chain. In addition, the software module makes it very easy for you to integrate the marking laser into your entire system consisting of database, measurement technology, and other components.

The TruTops Mark Station 7000 can be combined with numerous TRUMPF marking laser series, thereby offering the right solution for any application.

Additional options for the TruMark Station 7000 optimize production processes and improve user-friendliness.

Increase your process reliability with VisionLine, TRUMPF's image processing solution. VisionLine detects the position of the component and ensures that marking takes place in the correct location. It is also possible to read out and check the marked code. The modular structure opens up numerous options. Whether the camera looks through the scanner lens, is laterally installed or whether the machine uses one or two cameras – anything is possible.

You can implement high-quality markings even on cylindrical workpieces with the help of the optional rotary axes. A rotary axis with stepping motor enables circumference marking of components.

A guide carriage installed on the machine frame, operated by a program-controlled servo drive enables precise positioning of your components. The traverse path is 14.75 in., the repetition accuracy is typically ±0.001 in., and the traverse speed is 49 ft/min.

A precise spot extraction system is used in the work area, with a differential pressure sensor allowing for filter monitoring.

In the event of an error, TRUMPF service experts will remotely access your laser via a secure remote connection. In many cases the fault can be remedied directly in this way, or the configuration of the laser can be modified in a way that permits you to continue manufacturing until the spare part arrives.

The optional touchscreen also makes control easier for you and increases productivity. At the same time, the newly designed operating panel with its versatile functional buttons ensures intuitive handling and a simple set-up operation.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

Find your perfect marking laser now

Use the TruMark product finder to discover which marking laser is best suited to your application!