The innovative design of the TruMark Series 3000 with air cooling is characterized by its compact design. The supply unit fits very easily into your switch cabinet.

All-around marking solution

The marking lasers of the TruMark Series 3000 are available in the green and UV wavelengths. These wavelengths allow you to primarily mark and process polymers and non-ferrous metals such as copper and aluminum. The laser also offers impressive peak pulse powers of up to 100 kW and a high pulse-to-pulse stability. This means you always achieve the best in terms of quality and performance for your application. The modular design means that you can adapt your marking lasers to perfectly meet your needs. One particularly convenient feature is that the software-controlled focal position adjustment, pilot laser, and mechanical beam trap are integrated in the laser head, even though the TruMark Series 3000 is extremely compact.

Excellent beam quality, high pulse-to-pulse stability, high peak pulse powers, and short pulses.

The compact dimensions and the modular design make integration easy for you.

Different wavelengths (green and UV) for polymers and non-ferrous metals such as copper and aluminum.

IP safety class 54, air cooling, electrical and optical components are strictly separated.

The moderate power and high pulse energy mean that you can work even more productively.

Enables the focal position to be moved quickly using variable beam expansion.

Discoloration

If the material and laser wavelength are optimally matched, the dye molecules in the material can be deliberately discolored or faded. The surface remains smooth.

Ablation

Ablation partially removes thin top layers of multi-layer plastics which are applied to the basic material and have very different colors. This process can be used for the "day and night design", for example, which is used in the automotive and other industries.

Foaming

During foaming, the laser heats the plastic to cause a short melting process. During the subsequent cooling process, small gas bubbles become trapped and diffuse the light that falls on them and is reflected. This type of laser marking produces a raised marking.

|

TruMark 3330

|

TruMark 3230

|

|

|---|---|---|

| Laser parameters | ||

| Beam quality (M²) | < 1.5 | < 1.2 |

| Wavelength | 355 nm | 532 nm |

| Pulse repetition frequency | 1 kHz - 120 kHz | 1 kHz - 100 kHz |

| Minimum focal diameter | 16 μm with focal length 4 in. | 15 μm with focal length 4 in. |

| Maximum text field size | 220 mm x 220 mm for focal length 330 mm | 230 mm x 230 mm with focal length 13 in. |

| Structural design | ||

| Dimensions of laser head (W x H x D) | 138 mm x 207 mm x 450 mm | 138 mm x 138 mm x 380 mm |

| Dimensions of supply unit (W x H x D) | 445 mm x 465 mm x 420 mm | 445 mm x 465 mm x 420 mm |

| Installation | ||

| Protection class | IP54 | IP54 |

| Ambient temperature | 15 °C - 40 °C | 15 °C - 40 °C |

The technical data of all product versions as a download.

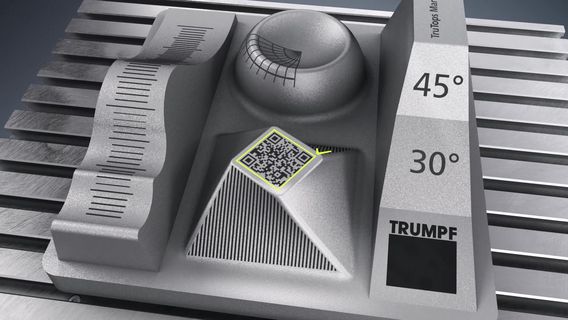

TruTops Mark

The TruTops Mark marking software makes marking with TruMark lasers as easy as possible. The TruTops Mark program combines the marking software, CAD editor, management of laser parameters and interfaces, sequence programming with QuickFlow, and a diagnostics tool. An intuitive interface puts all the functions at your fingertips. You can easily draw and arrange graphic objects with the CAD editor. The database for laser parameters enables you to re-use optimized parameters many times over. You can use the QuickFlow sequence programming to create "drag and drop" programs that control the complete marking cycle from beginning to end. The diagnostics tool visualizes and analyzes the analog measured values recorded by its sensors.

The other options for the TruMark Series 3000 optimize your production process and help to improve user-friendliness.

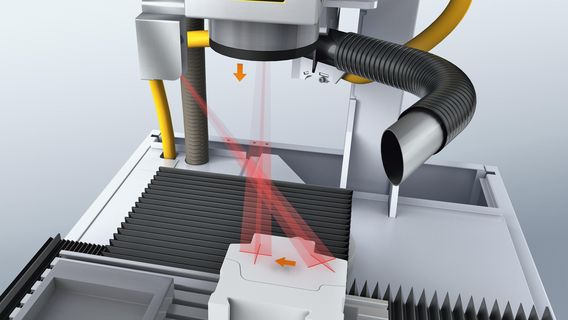

Increase your process reliability with VisionLine, TRUMPF's image processing solution. VisionLine detects the position of the component and ensures that marking takes place in the correct location. It is also possible to read out and check the marked code. The modular structure opens up numerous options. Whether the camera looks through the scanner lens, is laterally installed or whether the machine uses one or two cameras – anything is possible.

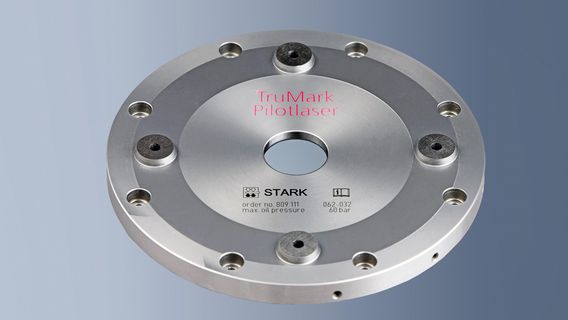

The pilot laser is used to simulate the marking content with a visible red light via a laser diode. This gives you an idea of the marking results in advance so you can position the component in the marking field even more easily.

The focus finder provides visual assistance for manually setting the correct working distance for the relevant application. It can be used for various focusing lenses.

The interfaces determine how simple it is to integrate a laser in a machine or production line. The lasers in the TruMark Series 3000 can be connected to a Profibus/Profinet/EtherCAT network and controlled. External devices can also be connected and automation systems provided by the customer can be integrated. The IOE interface expansion offers 16 additional digital inputs and 16 digital outputs, as well as 8 digital high-speed inputs and 8 digital high-speed outputs for connecting external devices, and for integrating the laser in the automation systems.

There are many focusing lenses available in different focal lengths for all wavelengths of the TruMark Series. You can select the optimum combination of wavelength and focal length for every application.

In the event of a fault, TRUMPF service experts will remotely access your laser via a secure remote connection. In many cases the fault can be remedied directly in this way, or the configuration of the laser can be modified in a way that permits you to continue manufacturing until the spare part arrives.

The operating package consists of a monitor and a keyboard with mouse. These are optimally designed for the needs of laser marking.

You will find the ideal workstation option for your particular workpiece size and application complexity from our workstation product line. This includes small, compact marking stations and systems for particularly large components. You can also benefit from various options for automation.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

Find your perfect marking laser now

Use the TruMark product finder to discover which marking laser is best suited to your application!