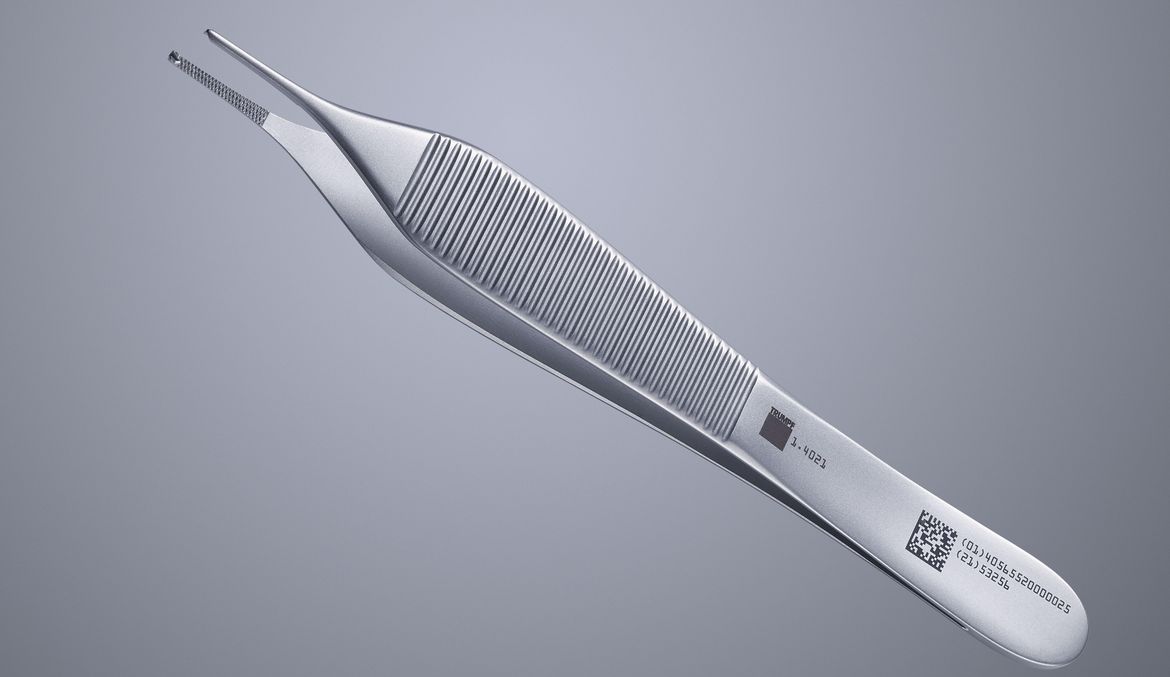

With its ultrashort laser pulses, the TruMicro Mark series is the ideal partner for applying high-quality UDI codes. Legislators around the world subject medical technology to high quality standards in terms of permanent readability and corrosion resistance. Therefore black marking has become the process of choice.

Comprehensive solution for marking applications with ultra-short pulses

The TruMicro Mark Series is characterized by maximum process reliability and precision. By using multi-level laser power control and monitoring the pulse energy for each individual pulse, you achieve precise marking results that meet the highest standards, especially in areas such as medical technology. Whether you are working with complex 3D free-form geometries or scanning marking content, the TruMicro Mark series in combination with image processing software is available as a turnkey solution. This gives you a wide range of options for "cold" microprocessing and surface modification.

Create deep black, corrosion-resistant markings with extreme peak pulse power, ultrashort laser pulses in the picosecond and femtosecond ranges, and the highest beam quality for absolute precision.

The ultra-fast power modulator keeps power and pulse energy at an exact level and can be transferred from one laser to another.

Mark implants and surgical instruments - corrosion-free and UDI-compliant. We would be happy to support you with our IQ/OQ services in the qualification process in order to meet the certification requirements of your industry.

The TruMicro Mark series offers an impressive range of marking and microprocessing applications. It is available as an OEM version and as a fully integrated and turnkey complete system in a TruMark station.

The TruMicro Mark 2030 allows flexible setting of the pulse duration to cover a wider range of applications. This includes black marking, high-quality engravings and extremely precise drilling and cutting.

High average power, small focal diameter, telecentric lenses - with the special features of the TruMicro Mark 2030 you are well-equipped for precise and efficient microprocessing.

Achieve excellent processing results in the entire 2D & 3D marking volume with the TruMicro Mark 1020. Due to the highly dynamic optical Z-axis of the laser in combination with a scanner optics unit, the focus is adjusted in three dimensions.

The TruMicro Mark 1020 even enables unlimited black marking. This allows you to place jet black and corrosion-resistant markings on complex three-dimensional shapes and in free form.

Limited edition engraving of a Junghans watch

The limited edition Meister S Chronoscope Platin Edition 160 from the watch and clock maker Junghans gets watch enthusiasts' pulses racing around the world. Only twelve watches will be marketed. The edition engraving along with the limited edition number was applied to precious platinum by a TruMicro Mark 2030 in a TruMark Station 7000.

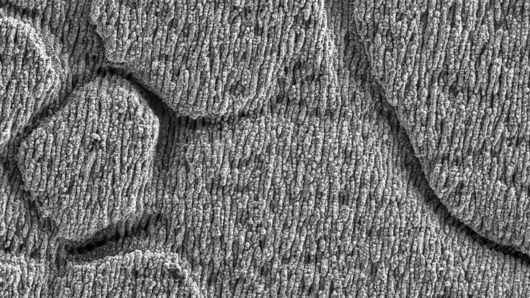

Black marking

The TruMicro Mark 1020 and 2030 can implement a color change in metals, up to and including deep black, which is known as black marking. Ultrashort laser pulses create virtually no heat in the material during processing. The amount of free chromium in the stainless steel thereby remains high enough for a self-healing layer of chromium oxide to form on the surface – the marking on stainless steel thereby becomes corrosion-resistant. Black marking is, therefore, especially well-suited for creating the mandatory markings in medical technology.

Rainbow Marking

The TruMicro Mark 1020 structures complex freeform 3D component shapes, like those of a gecko, with incomparable quality.

Laser marking in medical technology

Traceability is extremely important in the manufacture of products in medical technology, which is why machine-readable markings are very important. With the TruMicro Mark series, the type and form of the marking is not subject to any limits in the following tasks: UDI-compliant product markings in clear text and barcode or data matrix code for product traceability, micro-marking in the range of hundredths of millimeters, or graphics of the highest quality.

Unlimited Black Marking (3D)

The TruMicro Mark 1020, in particular, uses unlimited black marking to mark complex three-dimensional objects such as this stent tube from Alpine Laser in free form, giving it deep black and corrosion-resistant properties.

|

TruMicro Mark 2030

|

TruMicro Mark 1020

|

|

|---|---|---|

| Laser parameters | ||

| Beam quality (M²) | < 1.3 | < 1.3 |

| Wavelength | 1030 nm | 1030 nm |

| Average output power | 20 W | 10 W |

| Pulse duration | 900 fs , 20 ps, 400 fs - 20 ps (variable) | 900 fs |

| Maximum pulse energy | 20 µJ , 100 µJ | 100 µJ |

| Maximum repetition rate | 1000 kHz , optional 2000 kHz | up to 2500 kHz |

| Structural design | ||

| Dimensions of supply cabinet (W x H x D) | 600 mm x 1225 mm x 825 mm | 446 mm x 222 mm x 495 mm |

| Dimensions of work station (W x H x D) | 860 mm x 2000 mm x 1312 mm | 1150 mm x 1420 mm x 2000 mm |

| Dimensions of laser head with scanner (W x H x D) | 838.5 mm x 375 mm x 180 mm | 144 mm x 161 mm x 574 mm |

The technical data of all product versions as a download.

TruTops Mark 3D

3D marking with TRUMPF marking lasers has never been so quick and easy. Our user-friendly TruTops Mark 3D software significantly shortens processing times. You can now mark multiple objects in the volume with a single laser system, even on inclined and curved surfaces. In addition to the marking software, we offer a comprehensive 3D CAD editor to create workpieces and derive 3D marking drawings.

With useful added options, you can work even more efficiently and with more process reliability with your TruMicro Mark.

The pilot laser is used to simulate the marking content with a visible red light via a laser diode. You get an idea of the marking results in advance so you can position the component in the marking field even more easily.

With VisionLine image processing, you get additional quality assurance for your production. Whether workpiece recognition or reading and evaluating Data Matrix Codes – with its modular structure, we always have the right solution for your process.

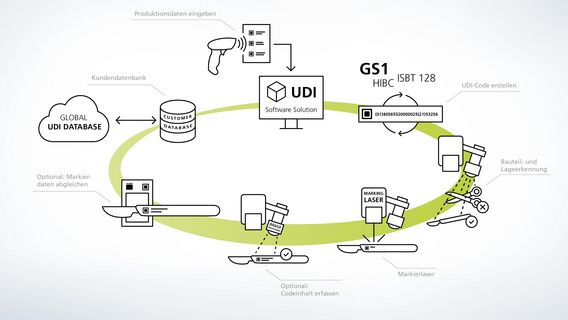

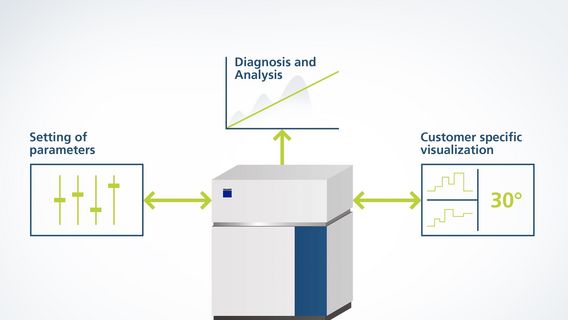

Our software solutions enable you to easily connect the marking system to your external peripherals or database. This allows you to read out and write back production-relevant data. Use this complete integration to increase your efficiency and ensure smooth processes in your production.

Interfaces are key for the integration of a TruMicro Mark laser into your machine or production line. The solid-state lasers from TRUMPF offer interfaces to all common fieldbus systems.

In the event of an error, TRUMPF service experts will remotely access your laser via a secure remote connection. In many cases the fault can be remedied directly in this way, or the configuration of the laser can be modified in a way that permits you to continue manufacturing until the spare part arrives.

QCW is used to melt the surface, giving a glossy surface finish.

Burst mode is the first choice when coarse processing, such as deep engraving, is needed. The number of pulses and their intensity can be controlled, allowing better control over the engraving depth.

In our work station product portfolio you will find the ideal work station for your particular workpiece size and application complexity. This includes small, compact marking stations and systems for particularly large components. We also offer automation options.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

Find your perfect marking laser now

Use the TruMark product finder to discover which marking laser is best suited to your application!

Find out more about high-quality, burr-free metal engraving.