1. Battery pack and tray

Using the laser, all interior parts of a battery as well as its housing are welded with a high degree of precision – and always with process reliability thanks to an intelligent sensor system. The precision tool is a winner in the manufacturing and integration of cooling systems in batteries as well.

Find out more

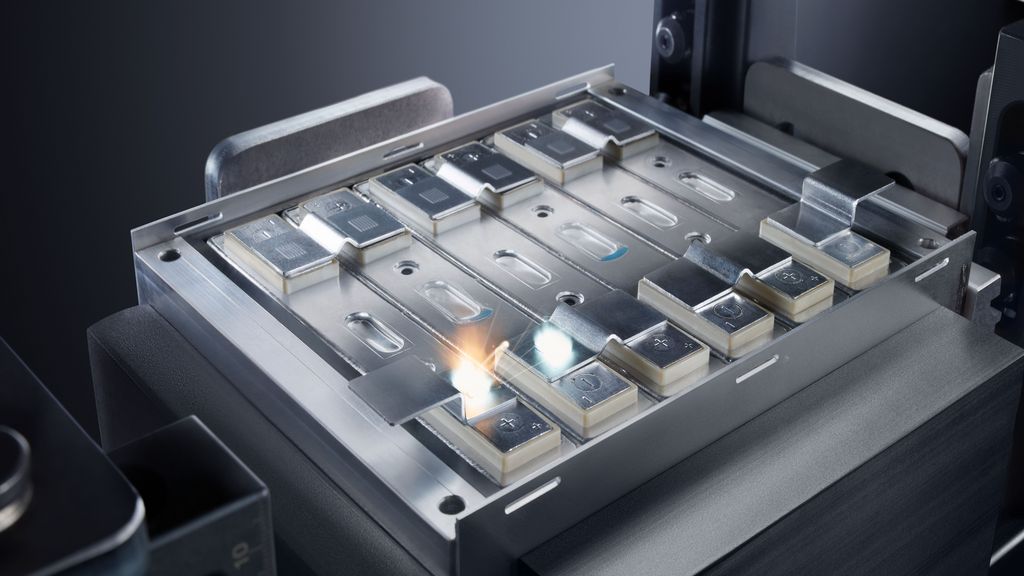

2. Battery cells and modules

Battery cells are connected into modules or packs with the busbar welding procedure. The live rail is designated as the busbar. Prismatic cells or cell modules can be connected with like materials (Al/Al or Cu/Cu) as well as with mixed combinations (for example, Al/Cu).

Find out more

3. Power electronics

You can achieve pinpoint contacting in complex electronic control units with the laser. Our lasers with green wavelength and sufficient power mean that copper contacts in electric cars can be processed highly productively and practically without any spatter.

Find out more

4. Powertrain

Whether it is a differential, hairpin, busbar, rotor shaft, gear wheel, stator or its housing – regardless of the electric drive component, laser processing makes the more compact design possible in the first place.

Find out more

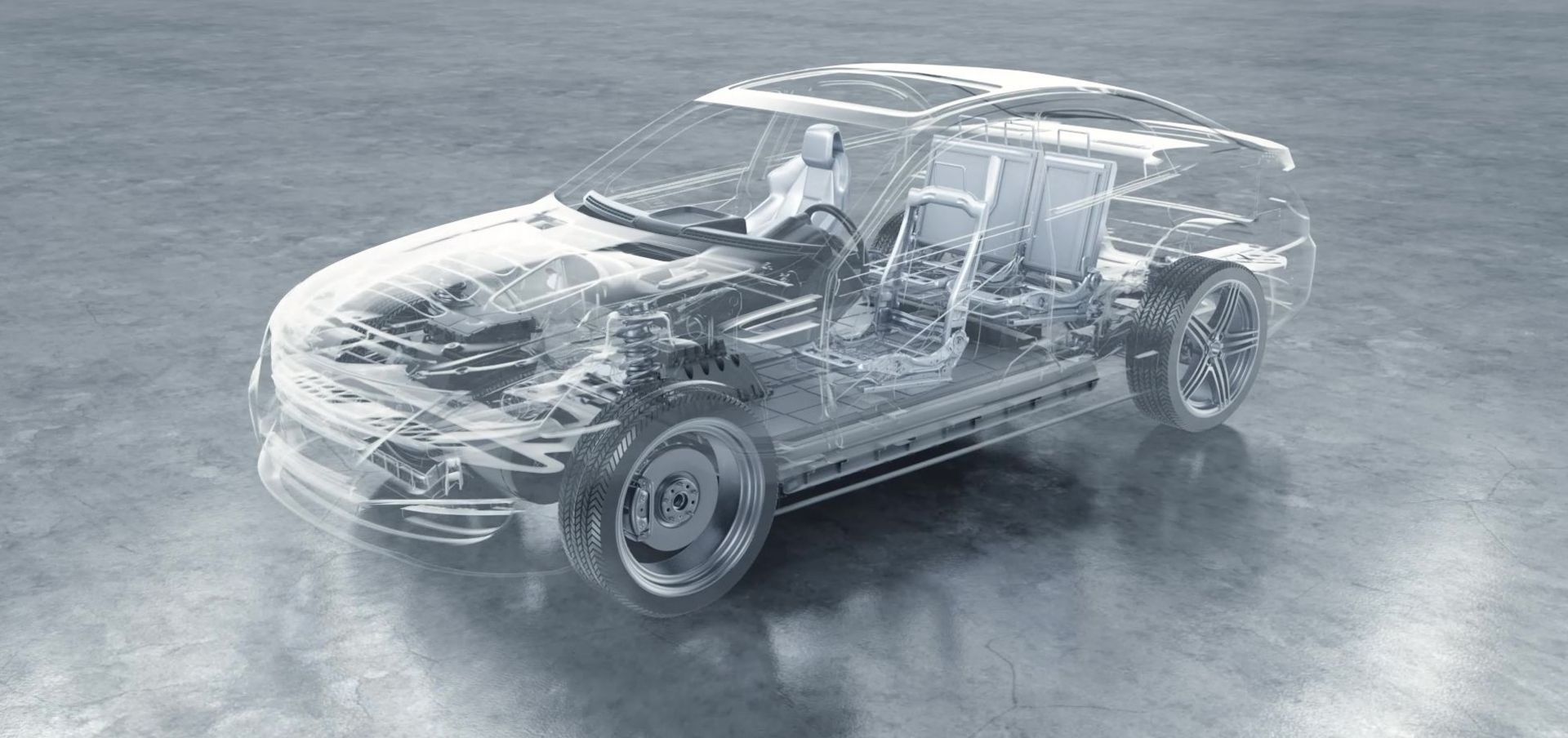

5. Lightweight design

TRUMPF lasers and machine tools make many lightweight designs possible in the first place. Thanks to accurate and precise production, considerable savings can be made in terms of weight and material during the manufacture of the automobile body.

Find out more

6. Automated production solutions for e-mobility

Satisfy your material requirements with intelligent sheet metal construction for e-mobility. TRUMPF provides you with automated production solutions for this purpose which are highly productive in small or fluctuating lot sizes.

Find out more