When it comes to business, Michael Wagner takes a pragmatic approach. If technical constraints prevent him from processing customer inquiries with his existing machinery, he acts right away and installs new systems in his production halls. His new, large-format bending machine is a case in point: to enable him to easily bend long parts made from four- or five-millimeter sheet steel, the company owner has added a TRUMPF VarioPress 500 with a length of nine meters and a press force of 500 metric tons to his machine fleet.

Previously, even with his most advanced system, he increasingly found himself up against seemingly insurmountable challenges: “Until recently, our swivel bending machine allowed us to work parts with a length of ten meters, but unfortunately only up to a thickness of three millimeters,” Wagner says. That’s pretty good, but unfortunately not good enough, because: “On our old VarioPress, we were able to process the frequently requested four-millimeter-thick edge parts only up to a length of 6.5 meters.” Wagner did not hesitate for long, concluding: “I need more flexibility in my production hall!”

From workshop to 5,000 square meters

Flexibility is a catchword that truly characterizes Wagner’s company in Herbolzheim, Germany. Founded by his grandfather Robert as a sheet-metal workshop back in 1910, the company has developed under the management of Michael’s father Karl-Heinz into a specialist for roofs and facades made of aluminum or steel. Whereas Robert Wagner plied his trade in a small workshop in nearby Riegel, the CNC sheet-metal processing company run by Michael Wagner is housed in a Herbolzheim production hall recently enlarged to 5,000 square meters. In total, the company employs 23 people here: six in sheet-metal processing and the remainder work for Karl-Heinz Wagner in facade and roof production, at the sheet-metal workshop, and on sanitary installations and heating.

High vertical range of manufacture

“We are all dependent on the construction industry, which means that our workload is subject to seasonal fluctuations. That’s why we choose to operate only one shift all year to see us all through the quieter periods,” Michael Wagner says. As a rule, nearly all production work is done in-house, with the CNC sheet-metal processors supplying the other business divisions. “This gives us an obvious advantage over our competitors, who have to buy many things that we can produce in-house,” the 36-year-old explains.

Anything is possible

Besides major customers, for whom he executes orders of between 15 and 20 metric tons, Wagner’s customer base is made up of many low-volume customers – craftspeople as well as private individuals who order one-of-a-kind products. To ensure his company can supply all customers within 48 hours, Wagner maintains a well-stocked warehouse. Regarding painted steel sheets alone, there are 52 RAL colors to choose from (note: refers to the RAL company in Bonn, Germany). Apart from sheet steel between 0.75 and five millimeters in thickness, Wagner also processes galvanized sheet steel, aluminum, titanium zinc, copper and stainless steel.

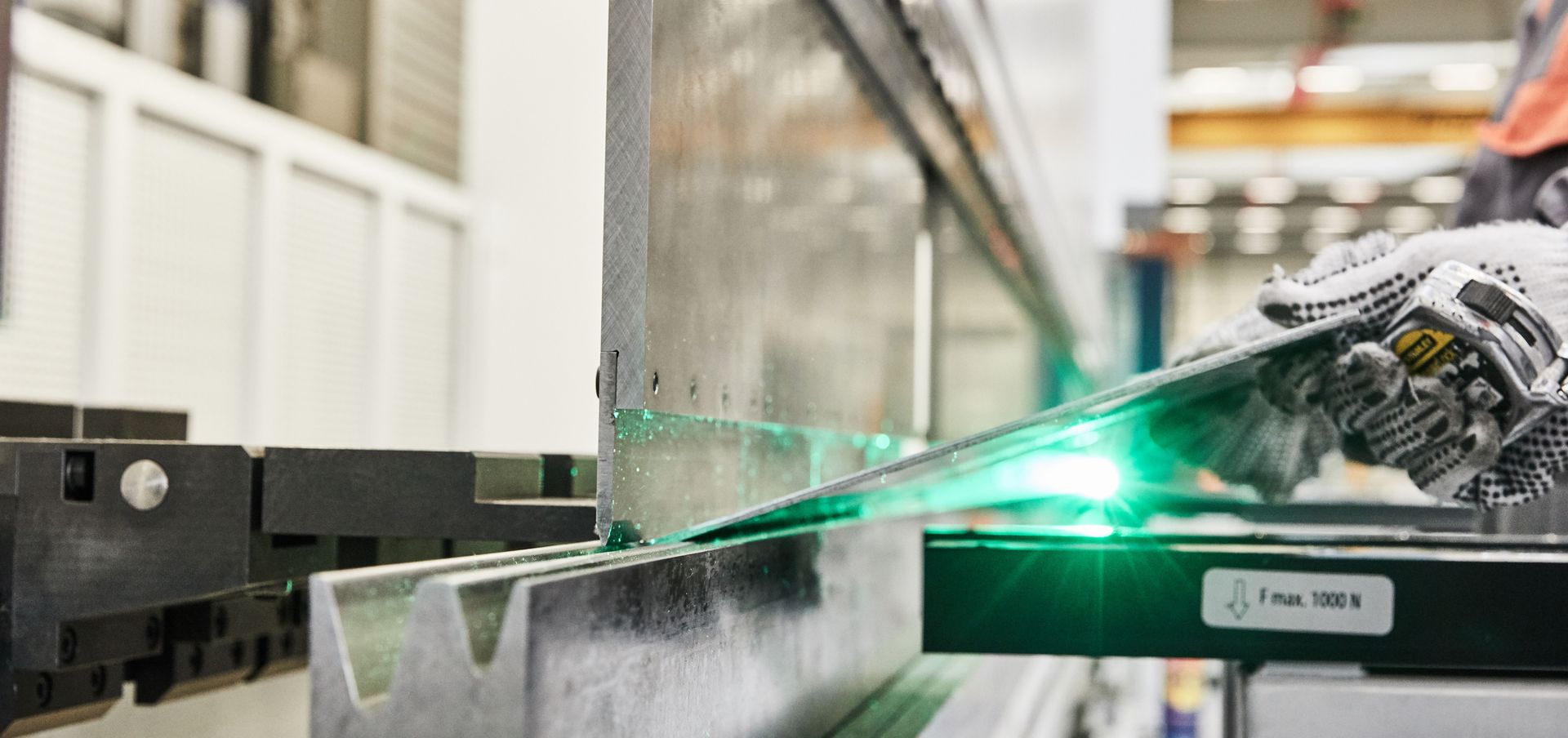

To enable him to process all these materials to perfection – even for a batch size of one – Wagner has equipped his new TRUMPF VarioPress 500 with many extras that guarantee outstanding production quality. The backgauge system, for example, is coupled with CNC-controlled bending aids and a clamping device. Thanks to these and the support brackets at the front, it’s possible to prevent long, thin metal sheets from sagging and to guarantee gentle, precision workmanship. “These extras also reduce the strain on my staff,” Wagner adds. He also expects the die movement along the entire nine meters of the embedded machine to provide flexibility: “All in all, we have made it possible to expand our portfolio. The press force and the bending length of nine meters grant us flexibility and new opportunities.”

One thing leads to another

As well as the TRUMPF VarioPress 500, Wagner has also invested in a new decoiling system. This allows him to cut sheet metal directly from coils. In his eyes, this was a perfectly logical way to go, because: “With our existing system, I could coil materials with thicknesses of up to just three millimeters. However, our investment in the large press meant we needed a decoiler that can cope with as much as five millimeters.”

Wagner believes that quality, speed and reliability are the cornerstones of his company’s success. These are attributes he also appreciates in his partners: “We are extremely satisfied with our existing EHT and TRUMPF machines. Thanks to our proximity to Teningen, technicians can be on site quickly should any issues arise. I am pleased that TRUMPF and EHT now offer customized bending machines. And I’m confident that I’ve chosen the right partners and that my investment will pay off.”