Daniel Weller is a joining technologies expert at German automotive supplier ElringKlinger. He develops joining processes in the field of battery technology. When it comes to welding cell contacting systems (CCS) for electric vehicles, he and his colleagues face a number of challenges. Alongside a desire for more speed, there is also the question of how to accommodate a big range of variants in conjunction with a zero-defect strategy. The components in question are up to two meters long and involve upward of 50 welding positions. “Our job is to develop a stable production process that delivers a consistent level of quality at short cycle times,” Weller explains.

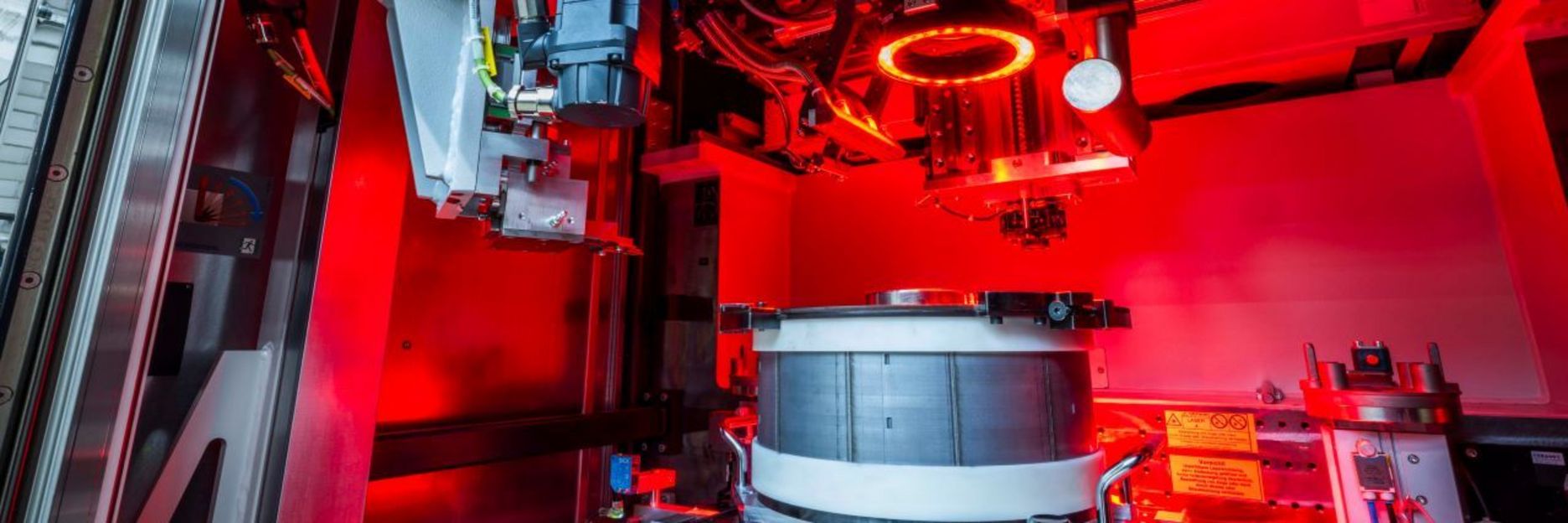

For hairpin welding of stators, EasyModel AI rapidly and precisely detects hundreds of weld points in a mass-production setting.

Until recently, detection of the correct welding position under real production conditions required a lot of know-how plus some clever tricks to tackle problems: varying light conditions, reflections, dust and minor deviations in geometry. Weller looks back and says: “Of course, we got along fine with the previous solution, but TRUMPF’s AI-supported EasyModel AI solution now brings considerable speed to weld spot detection and thus to the entire process development.”

A few training images suffice

Using TRUMPF’s image-processing solution VisionLine Detect, Weller records a few training images of the component and uploads them to the AI cloud. He then marks relevant areas on the images. After just a few photos, the AI model is able to precisely filter relevant from irrelevant areas of the image, binarize the relevant ones (the detected component is displayed in white, the surrounding area in black) and reliably detect the edge of the component, even at short cycle times. For Weller and ElringKlinger, this means much greater efficiency in feature detection: “It no longer takes days to achieve good results, but merely hours.” Equally impressive are the accurate, reproducible results in a mass-production environment, along with the fact that no programming knowledge is required to operate EasyModel AI. “The system works on the principle of ‘what you see is what you get’–it’s intuitive, fast and zero code.”

Learning on the job

Germany’s automotive and industrial supplier Schaeffler is likewise using EasyModel AI to accelerate development of new processes and boost production throughput. Alexander Fast works at the company’s Bühl site, developing advanced laser-welding processes for copper in electric motors. “When laser welding copper wire for the stator winding of an electric motor,” he explains, “the problem is that any deviation in the position of the pieces to be joined – including height difference, lateral offset or gap formation – will impact the ability of the equipment to properly detect the component and perform the weld. And we’re talking here about anything from 20 to several hundred weld points, depending on the type of component.” Conventional detection systems, which use grayscale images, tend to struggle here. “In terms of precision and reliability, the AI filter is way better at determining the welding position – even with variations in component characteristics and changing ambient conditions – than anything else currently on the market,” says Fast. “Its introduction has enabled us to significantly improve component detection – as shown in a first-pass yield of over 99 percent.” In addition, the system can statistically analyze the data, meaning that “only values with significant deviation need to be relabeled, and that saves valuable development time.”

EasyModel AI is now being used in production at Schaeffler worldwide. ElringKlinger, meanwhile, has rolled out the AI filter to two further production facilities, alongside its plant for future technologies in Neuffen, as part of the same project.