The user-friendly VisionLine programming interface provides an intuitive assistant to guide you through the programming process. All relevant production information is clearly displayed and supporting functions help with the optimum setting of the sensor units. Comprehensive online help is also available.

Process-synchronous quality control in welding

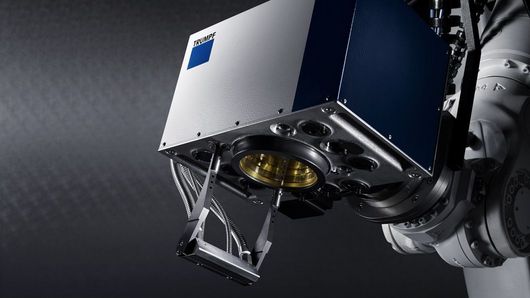

The VisionLine OCT Check process sensor system ensures reliable and precise welding depth monitoring. The use of optical coherence tomography (OCT) makes process-synchronous quality assurance possible, for example by measuring the keyhole depth in deep welding processes. The geometry of the solidified weld seam is measured by an additional OCT scan. Due to the optimal interaction of PFO and OCT, process-synchronous measurement of keyhole depth is possible in the entire work area of the PFO - with no parameter adjustment necessary.

The robust OCT design and clever integration into the optics system enable measurements even under fluctuating ambient conditions.

For minimal interfaces and simple integration of systems

User-friendly software interface

Fast availability of results for and low cycle times

Inspection of each component with 100% traceability of the welding depth along the entire weld seam

All VisionLine Detect and VisionLine OCT Detect features are already included.

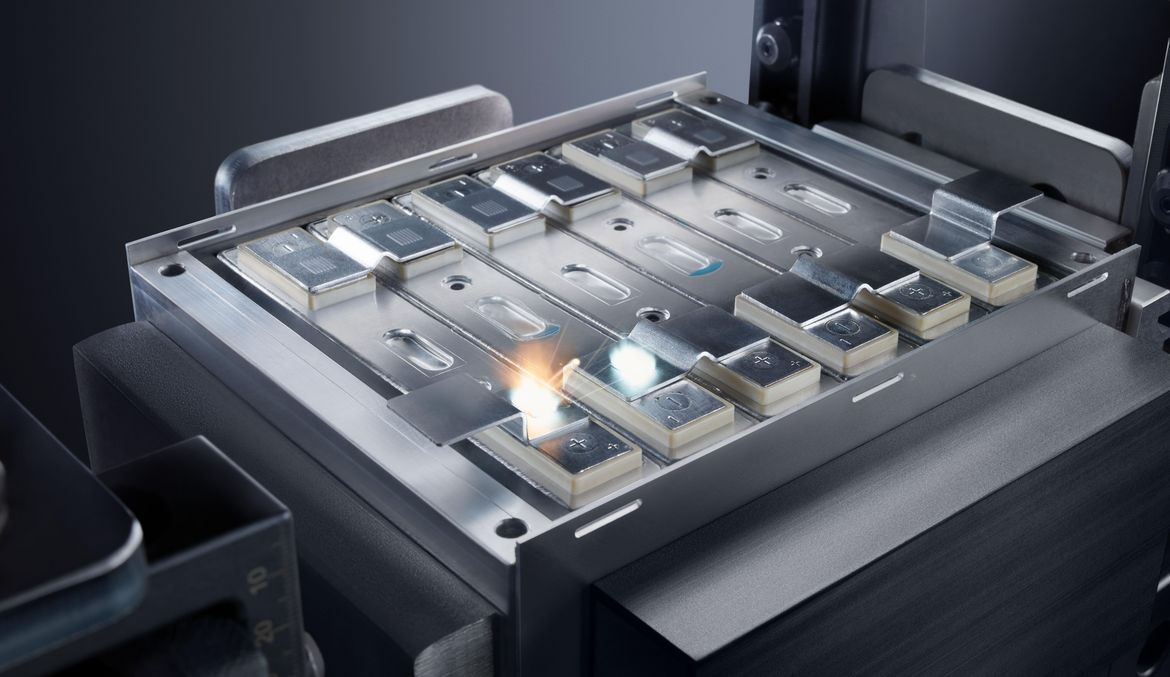

Welding busbars

Remote welding on automobile seats

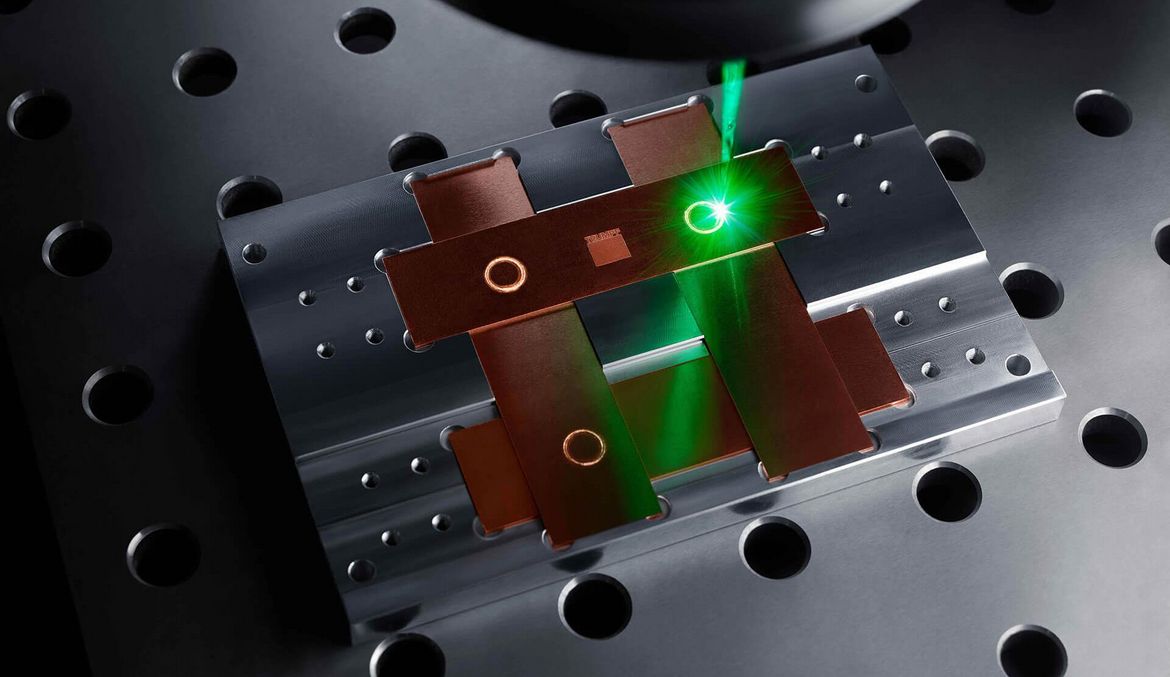

Copper welding

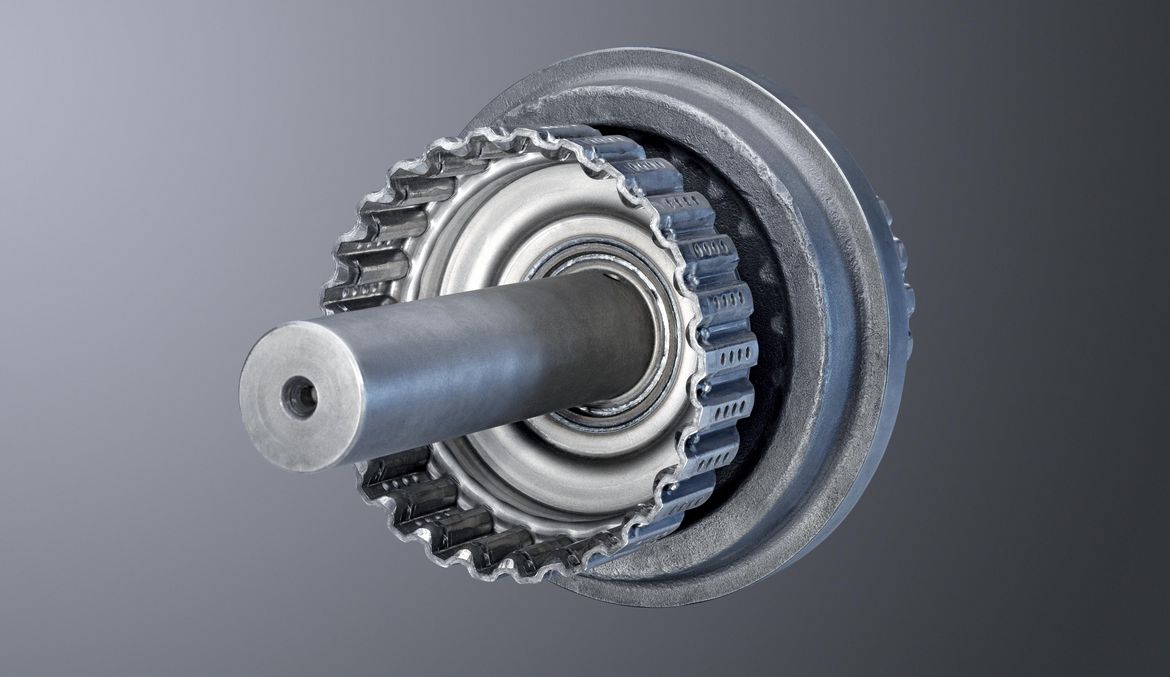

Deep welding of AIMg3 cast housings

Welding of drive components

|

VisionLine OCT Check

|

|

|---|---|

| Configuration | |

| Available lasers | TruDisk (1030 nm, 515 nm), TruFiber (1075 nm, Multi Mode) |

| Available optics | PFO 33 1 2 |

| Parameters | |

| OCT wavelength spectrum (laser class) | λ = 820 nm - 860 nm (Klasse 3B) |

| OCT sensor measurement rate | 250 kHz |

| Axial measurement range | ± 5 mm (je nach Brennweite) |

| Lateral measurement range | Ø 15 mm - 25 mm (je nach Brennweite) |

| Axial resolution | 12 μm |

| Lateral resolution | ≥ 2 μm (abhänglig von Parametern und optischem Aufbau) |

| Typical measurement range - welding depth measurement | 0.5 mm - 5 mm (je nach Prozessdesign und optischem Aufbau) |

The technical data of all product versions as a download.

With an additional service package, TRUMPF provides the complete solution for complex OCT and image processing tasks. Programming of the customized solution, including extensive documentation, is performed subject to a successful feasibility study.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

Footnotes-

Only available with PFO Generation 3.

-

Detailed information about the available optics settings can be found in the data sheet.