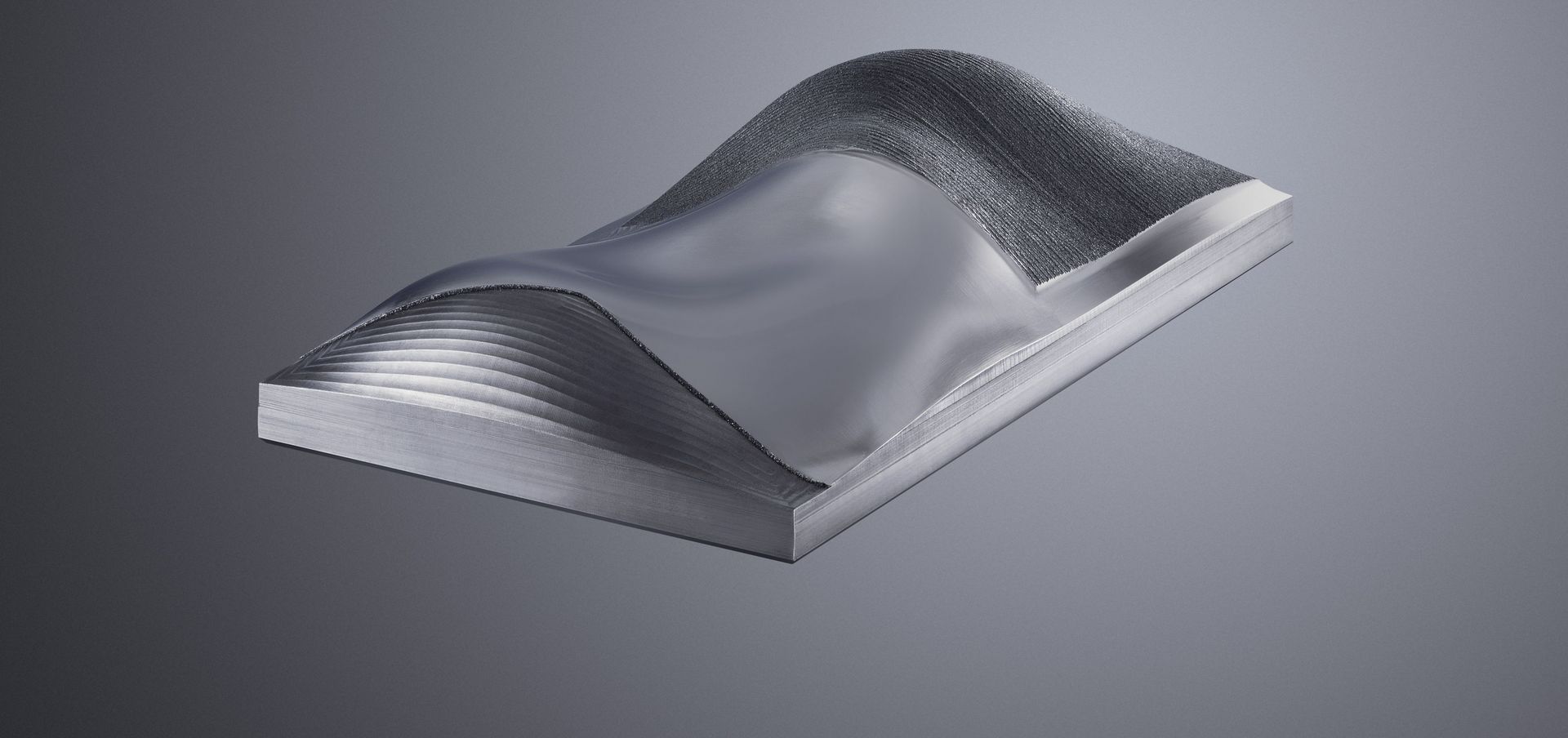

Surface processing with the laser

Whether for hardening, coating, cleaning or structuring – the laser can process surfaces with different dimensions easily and quickly. This is possible thanks to a very wide range of different beam sources with laser powers and properties which can be set precisely.

The benefits of surface processing with the laser

The laser can be used with great flexibility, even in 3D, thanks to tool-free, non-contact processing – mechanical wear and tear is a thing of the past.

Whether steel, copper or aluminum – a great number of the most varied of materials can be processed with the laser as a tool.

The laser facilitates a controlled, selective and precise process. Which means you benefit from reproducible results.

Due to the localized laser processing on the workpiece, basically no heat is applied to the workpiece, which greatly reduces any distortion on it.