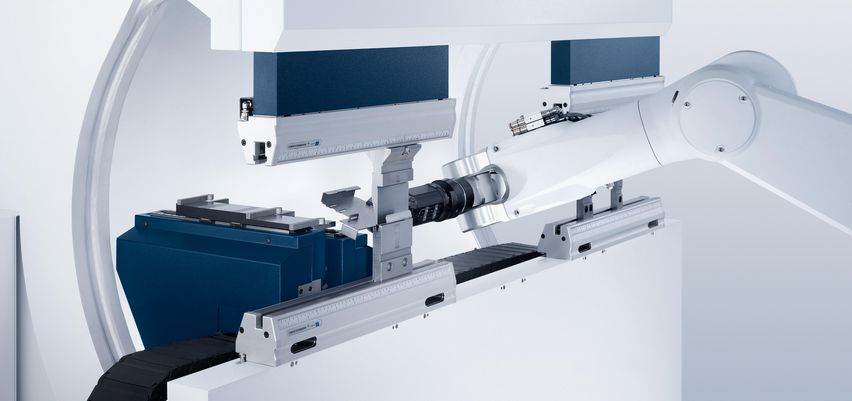

The split tool clamp ensures optimal use of the gripper, saving time-consuming regripping.

Innovative high-speed bending cell

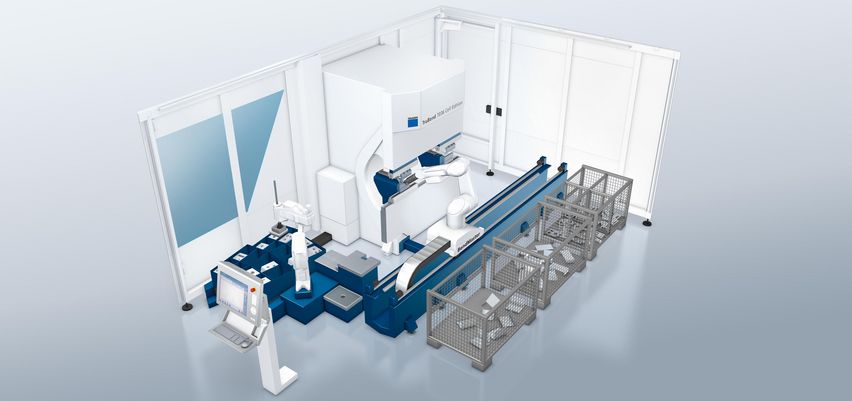

The TruBend Cell 7000 offers users a compact system for the highly dynamic, efficient bending of small parts.

Backgauges and a dynamic drive concept make the TruBend Cell 7000 the world's fastest small-part bending cell.

Now you can produce small parts up to 20x15 inches even more efficiently.

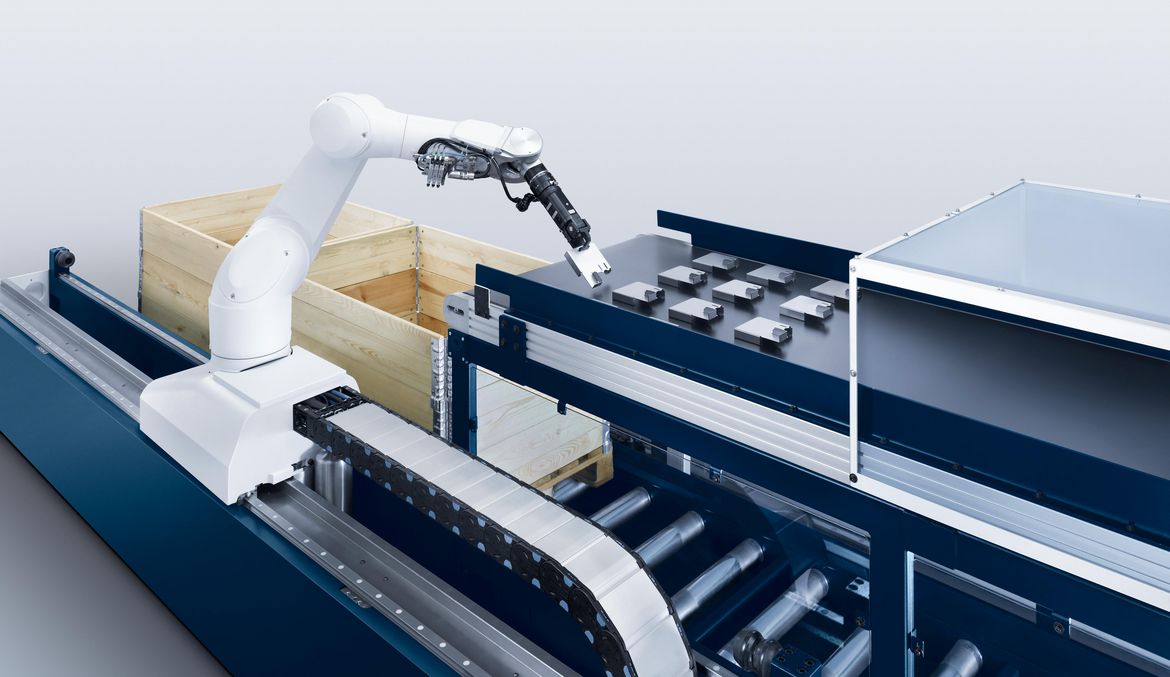

The conveyor system gives you flexible storage options for your finished parts.

First part, perfect part – with ACB.

The ToolMaster Bend sets up automatically.

The LoadMaster Bend loads quickly, reliably, and parallel to production.

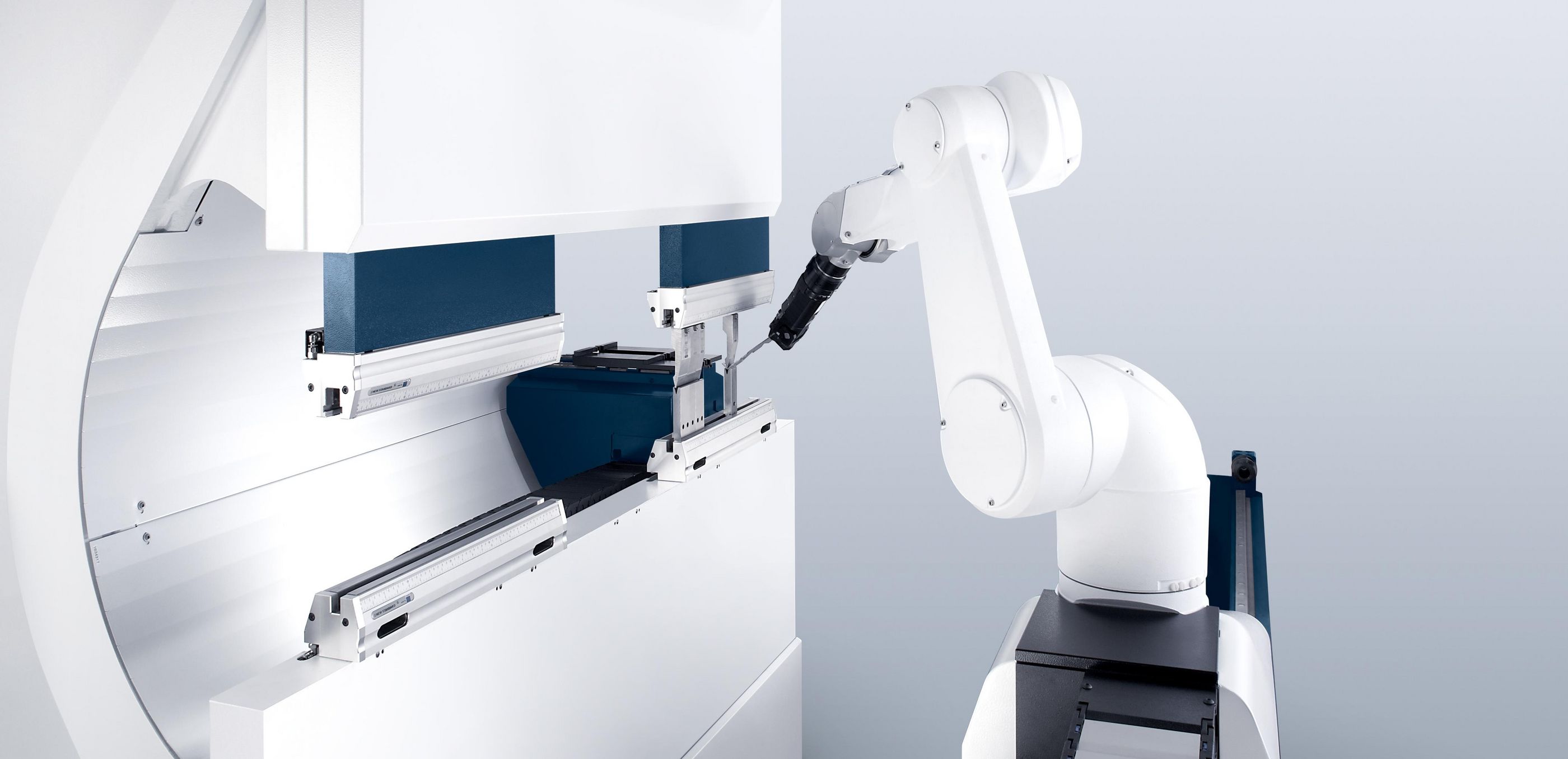

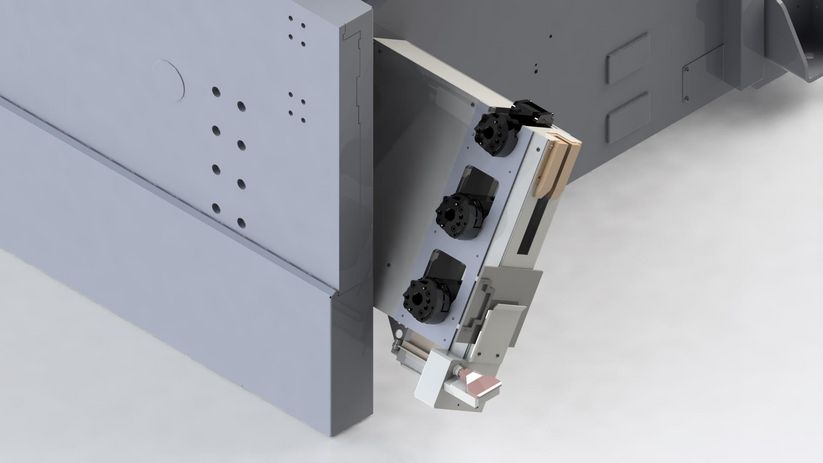

Mechanical gripper

The mechanical gripper enables the automated bending of small components. Its linear and rotary axes reduce time-consuming regripping.

|

TruBend Cell 7036

|

|

|---|---|

| Machine | |

| Press force | 360 kN |

| Width between columns | 1530 mm |

| Usable open height | 300 mm |

| Throat depth | 515 mm |

| Speeds | |

| Y rapid traverse | 220 mm/s |

| Max. Y-Arbeitsgang | 50 mm/s |

| BendMaster (15) | |

| Maximum carrying capacity | 15 kg |

| Maximum part weight | 1.5 kg |

| Maximum part weight with restricted speed | 3 kg |

| Maximum part size | 500 mm x 380 mm |

| Minimum sheet thickness | 0.7 mm |

| Maximum sheet thickness | 6 mm |

| Dimensions and weights | |

| BendMaster weight | 114 kg |

| Weight of basic machine | 4200 kg |

| TruBend machine | 5500 mm x 3870 mm x 2630 mm |

The technical data of all product versions as a download.

Numerous functions make your TruBend Cell 7000 a particularly fast and precise bending cell.

Completely automated

Tool changes made easy: the ToolMaster Bend automatically sets up the right tools.

A conveyor system places the finished parts in boxes or removes them onto the pallet conveyor.

The BendMaster gripper is changed automatically. A cleaning station cleans the tools for you.

Precision

You can achieve consistently precise angles using the tried-and-tested Automatically Controlled Bending angle measuring system – without any manual intervention.

ACB Wireless ensures perfect angles, particularly for short sides, reflective surfaces, or internal flanges. If required, the user-friendly system automatically corrects the angle; the communication between the tool and control is wireless.

TruTops Bend

Count on the best quality from the very first part. This is ensured during the programming of automated bending cells by TruTops Bend through the incorporated bending expertise of TRUMPF – in the form of bend deductions as well as algorithms for tool selection and the calculation of bending sequences.

Software

The extensive range of TruTops software supports you throughout the entire production process. Control your operational workflow in a simple and targeted manner, from managing your customer orders and purchasing processes to delivery of the produced parts. Through the direct coupling with the machine control, you can keep a constant eye on the status of your orders.

TruBend Cell 7000 bending tools are equipped with an ID chip. This enables the ToolMaster to detect the position, tool type, and the rotation of the tools completely automatically.

TRUMPF sensor tools function according to the tried-and-tested Automatically Controlled Bending measuring principle. Sensor disks, integrated in the tool shape, take measurements in the process zone. The sensor tools are equipped with a chip in the same way as the TruBend Cell 7000 standard tools.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.