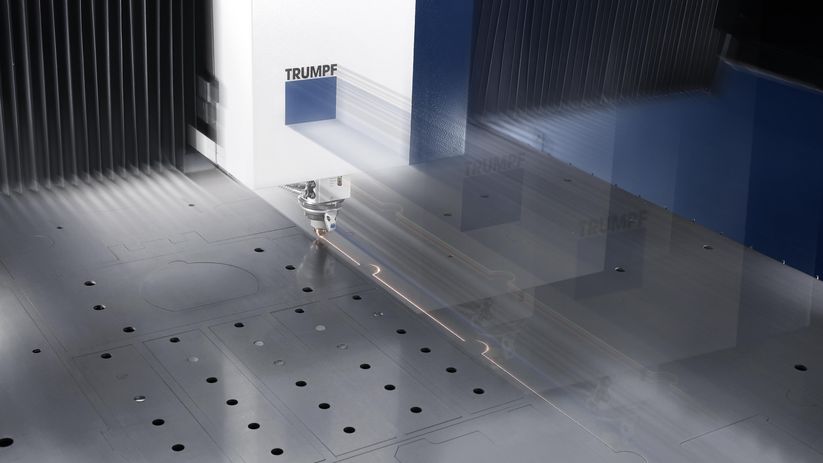

Stellen Sie sich vor, Sie fahren ein Auto mit 400 PS, – aber Ihr Auto kriegt das Können des Motors einfach nicht auf die Straße. Damit Ihnen das beim Laserschneiden nicht passiert, sind unsere Maschinen so konstruiert, dass die Leistung des Lasers auch komplett auf dem Blech ankommt. Das perfekt abgestimmte Gesamtpaket aus Maschine, Laserleistung und Funktionen erhalten Sie nur bei TRUMPF. Laserleistungen bis 24 kW nutzen Sie voll am Werkstück – das liefert beste Ergebnisse auch bei schwierigen Teilen.

Produktive Bearbeitung, reibungsloser Prozess

Die TruLaser 5030 fiber, TruLaser 5040 fiber und die TruLaser 5060 fiber überzeugen durch hohe Bearbeitungsgeschwindigkeit und reproduzierbare, hohe Teilequalität selbst bei komplexen Konturen. Dank des Festkörperlasers bis 24 kW Laserleistung erreichen Sie exzellente Vorschübe. Clevere Assistenzsysteme machen den kompletten Bearbeitungsprozess produktiver und zuverlässiger denn je. Die Bedienerbindung ist gering, die Nebenzeiten sind minimal.

Hohe Maschinendynamik dank leistungsstarker Antriebe und dynamischer Achsbewegungen, selbst bei komplexen Konturen.

Ausgezeichnete Teilequalität und reibungslose Entnehmbarkeit der Teile ermöglicht BrightLine fiber.

Ein neues Düsendesign reduziert Stickstoffverbrauch um bis zu 70 % – bei doppeltem Tafeldurchsatz.

Nutzen Sie die volle Laserleistung: Unsere Maschinen sind so konstruiert, dass jedes kW auch auf dem Blech ankommt. So schaffen Sie nicht nur hohe Vorschübe, sondern können das Werkstück auch produktiv bearbeiten.

Smart Nozzle Automation sorgt für eine hohe Düsenqualität - auch im vollautomatischen Betrieb. Der Düsenwechsler kann während des Schneidens aus der Maschine herausgezogen und hauptzeitparallel gerüstet werden.

Mit der mehrfach ausgezeichneten Touchpoint HMI lassen sich Bedienaufgaben deutlich schneller und intuitiver erledigen – bei gleichbleibend hoher Performance.

Bearbeiten Sie schnell und einfach Bleche im Format 6 x 2 m.

Mit der Funktion CoolLine schaffen Sie selbst feine Konturen in dickem Baustahl.

Mit 24 kW schneidet der TruDisk 24001 bis zu dreimal schneller.

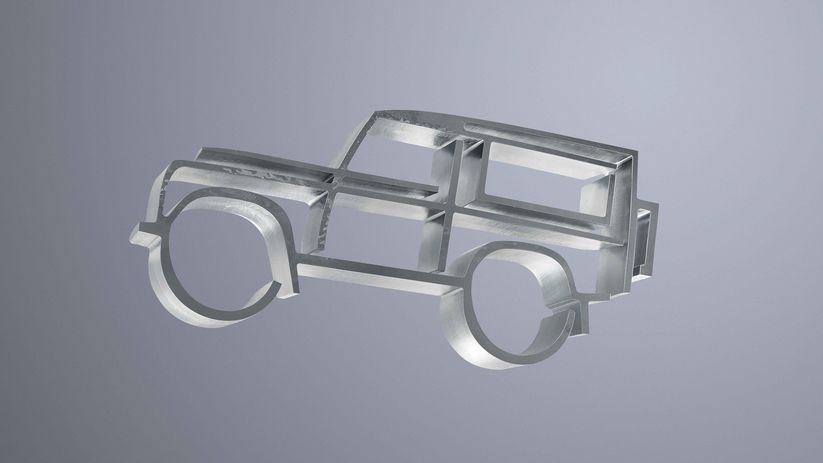

Dünnes Baustahlteil

Besonders im Dünnblech schneidet Ihre TruLaser Serie 5000 fiber extrem schnell

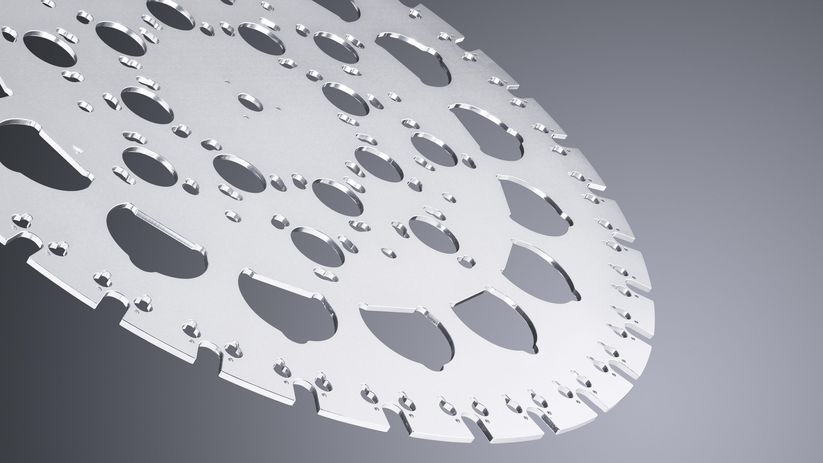

Leicht entnehmbare Teile

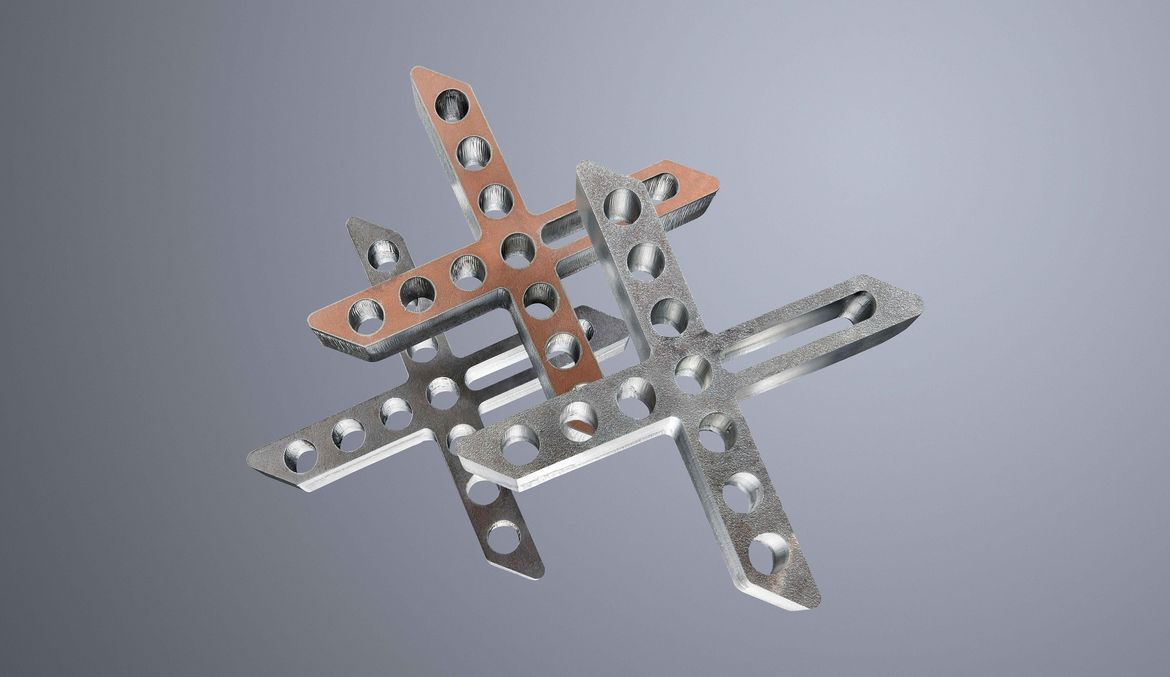

Mit BrightLine fiber, einer ausgeklügelten Kombination aus einer speziellen Optik in Verbindung mit den strömungsoptimierten BrightLine Düsen und weiteren technischen Innovationen, liefert die TruLaser Serie 5000 fiber höchste Teilequalität. Der Clou: Durch die hochwertigen Schnittkanten verhaken Ihre Teile bei der Teileentnahme nicht. Sie können die Teile leicht entnehmen und sparen viel Zeit.

Schneiden von allen gängigen Materialien

Der Aufbau des TruDisk ermöglicht die Bearbeitung von Buntmetallen mit Stickstoff – ohne Sorgen vor Rückreflexionen. TRUMPF ermöglicht außerdem die Bearbeitung von folierten Blechen.

Dicker Baustahl mit CoolLine geschnitten

Das Verfahren CoolLine kühlt das Werkstück während des Laserschneidens gezielt. Das ermöglicht neue Geometrien und erhöht die Prozesssicherheit bei der Bearbeitung von dickem Baustahl deutlich.

Dicker Baustahl

Stark und hochwertig: Der kraftvolle TruDisk 24001 schneidet spielend durch bis zu 50 mm dicken Baustahl.

Schwankende Stahl- und Oberflächenqualitäten schneiden mit FlexLine

Mit FlexLine schneiden Sie Baustahl unterschiedlicher Güte robust, sicher und hochwertig. Dafür sorgen spezielle Schneidparameter und ein patentiertes Düsendesign.

|

TruLaser 5030 fiber

|

TruLaser 5040 fiber

|

TruLaser 5060 fiber

|

|

|---|---|---|---|

| Abmessungen | |||

| Länge | 9229 mm | 11200 mm | 15500 mm |

| Breite | 6145 mm | 6373 mm | 6373 mm |

| Höhe | 2200 mm | 2200 mm | 2200 mm |

| Gewicht | |||

| Gewicht Grundmaschine | 11700 kg 1 | 14300 kg 1 | 18500 kg 1 |

| Maximale Geschwindigkeit | |||

| Simultan | 280 m/min | 280 m/min | 280 m/min |

| Arbeitsbereich | |||

| X-Achse | 3000 mm | 4000 mm | 6000 mm |

| Y-Achse | 1500 mm | 2000 mm | 2000 mm |

| Max. Werkstückgewicht ohne Schwerlastpalettenwechsler | 1100 kg | 2000 kg | 2900 kg |

| Max. Werkstückgewicht mit Schwerlastpalettenwechsler | 1800 kg | 3300 kg | 4900 kg |

| Max. Werkstückgewicht auf beiden Paletten mit Schwerlastpalettenwechsler | 2200 kg 2 | 3500 kg 2 | 5700 kg 2 |

| Laserspezifische Daten - TruDisk 6001 | |||

| Max. Laserleistung | 6000 W | 6000 W | 6000 W |

| Max. Blechdicke Baustahl | 25 mm | 25 mm | 25 mm |

| Max. Blechdicke Baustahl mit Schneidpaket Blechdickenerweiterung | 32 mm | 32 mm | 32 mm |

| Max. Blechdicke Edelstahl | 25 mm | 25 mm | 25 mm |

| Max. Blechdicke Edelstahl mit Schneidpaket Blechdickenerweiterung | 35 mm | 35 mm | 35 mm |

| Max. Blechdicke Aluminium | 25 mm | 25 mm | 25 mm |

| Max. Blechdicke Kupfer | 10 mm | 10 mm | 10 mm |

| Max. Blechdicke Messing | 10 mm | 10 mm | 10 mm |

| Laserspezifische Daten - TruDisk 8001 | |||

| Max. Laserleistung | 8000 W | 8000 W | 8000 W |

| Max. Blechdicke Baustahl | 25 mm | 25 mm | 25 mm |

| Max. Blechdicke Baustahl mit Schneidpaket Blechdickenerweiterung | 32 mm | 32 mm | 32 mm |

| Max. Blechdicke Edelstahl | 40 mm | 40 mm | 40 mm |

| Max. Blechdicke Aluminium | 25 mm | 25 mm | 25 mm |

| Max. Blechdicke Kupfer | 16 mm | 16 mm | 16 mm |

| Max. Blechdicke Messing | 10 mm | 10 mm | 10 mm |

| Laserspezifische Daten - TruDisk 10001 | |||

| Max. Laserleistung | 10000 W | 10000 W | 10000 W |

| Max. Blechdicke Baustahl | 30 mm | 30 mm | 30 mm |

| Max. Blechdicke Baustahl mit Schneidpaket Blechdickenerweiterung | 32 mm | 32 mm | 32 mm |

| Max. Blechdicke Edelstahl | 40 mm | 40 mm | 40 mm |

| Max. Blechdicke Aluminium | 30 mm | 30 mm | 30 mm |

| Max. Blechdicke Kupfer | 16 mm | 16 mm | 16 mm |

| Max. Blechdicke Messing | 12,7 mm | 12,7 mm | 12,7 mm |

| Laserspezifische Daten - TruDisk 12001 | |||

| Max. Laserleistung | 12000 W | 12000 W | 12000 W |

| Max. Blechdicke Baustahl | 30 mm | 30 mm | 30 mm |

| Max. Blechdicke Baustahl mit Schneidpaket Blechdickenerweiterung | 50 mm | 50 mm | 50 mm |

| Max. Blechdicke Edelstahl | 40 mm | 40 mm | 40 mm |

| Max. Blechdicke Edelstahl mit Schneidpaket Blechdickenerweiterung | 50 mm | 50 mm | 50 mm |

| Max. Blechdicke Aluminium | 30 mm | 30 mm | 30 mm |

| Max. Blechdicke Aluminium mit Schneidpaket Blechdickenerweiterung | 40 mm | 40 mm | 40 mm |

| Max. Blechdicke Kupfer | 16 mm | 16 mm | 16 mm |

| Max. Blechdicke Messing | 12,7 mm | 12,7 mm | 12,7 mm |

| Laserspezifische Daten - TruDisk 24001 | |||

| Max. Laserleistung | 24000 W | 24000 W | 24000 W |

| Max. Blechdicke Baustahl | 40 mm | 40 mm | 40 mm |

| Max. Blechdicke Baustahl mit Schneidpaket Blechdickenerweiterung | 60 mm | 60 mm | 60 mm |

| Max. Blechdicke Edelstahl | 40 mm | 40 mm | 40 mm |

| Max. Blechdicke Edelstahl mit Schneidpaket Blechdickenerweiterung | 60 mm | 60 mm | 60 mm |

| Max. Blechdicke Aluminium | 40 mm | 40 mm | 40 mm |

| Max. Blechdicke Kupfer | 16 mm | 16 mm | 16 mm |

| Max. Blechdicke Messing | 12,7 mm | 12,7 mm | 12,7 mm |

| Verbrauchswerte | |||

| Mittlere Leistungsaufnahme in der Produktion - TruDisk 6001 | 15 kW | 15 kW | 15 kW |

| Mittlere Leistungsaufnahme in der Produktion - TruDisk 8001 | 17 kW | 17 kW | 17 kW |

| Mittlere Leistungsaufnahme in der Produktion - TruDisk 10001 | 19 kW | 19 kW | 19 kW |

| Mittlere Leistungsaufnahme in der Produktion - TruDisk 12001 | 25 kW | 25 kW | 25 kW |

| Mittlere Leistungsaufnahme in der Produktion - TruDisk 24001 | 33 kW | 33 kW | 33 kW |

Die technischen Daten aller Produktvarianten als Download.

Hochproduktiv und in bester Qualität: Leistungsstarke Funktionen garantieren beste Bearbeitungsergebnisse.

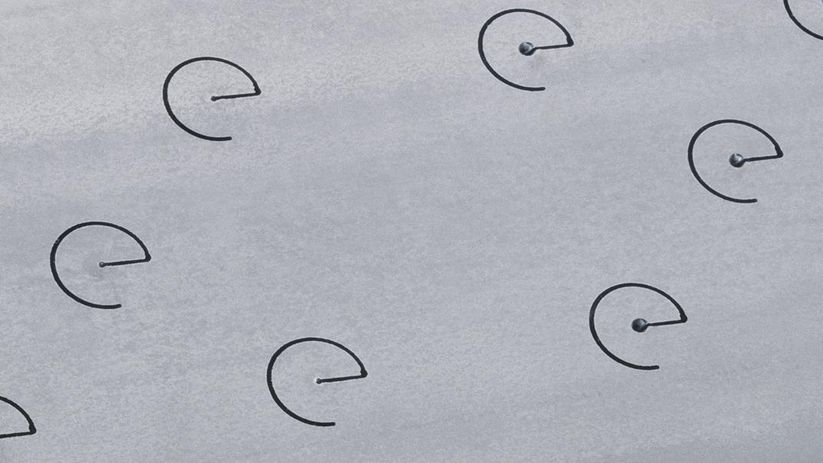

Prozesssicherheit und Bedienerunterstützung

Nanojoints ermöglichen – unabhängig von der Bauteilgeometire – eine prozesssichere und ressourceneffiziente Bearbeitung Ihrer Bauteile: höhere Produktivität, bessere Teilequalität und einfachere Teileentnahme dank minimaler Fixierung im Restgitter. In vielen Fällen ist keine Nacharbeit notwendig. Im Gegensatz dazu, fixieren Microjoints das Bauteil über die gesamte Blechdicke mit einem Haltesteg im Restgitter. Die sichtbare Konturverletzung erfordert in den meisten Fällen eine zeitintensive manuelle Nacharbeit der Bauteile. Die Teileentnahme ist bei dünnen Blechdicken aufwendiger, bei mittleren Blechdicken nahezu unmöglich.

Baustahl erhitzt sich beim Laserschneiden besonders stark und kann dadurch unkontrolliert schmelzen. Mit CoolLine passiert das nicht. Während der Bearbeitung sprühen Düsen mit präzisen Bohrungen Wassernebel kreisrund um den Laserstrahl auf das Werkstück. Die Verdampfungsenergie des Wassers bewirkt, dass das Material um den Laserstrahl gekühlt wird. CoolLine ermöglicht so neue Geometrien, eine engere Schachtelung und erhöht die Prozesssicherheit bei der Bearbeitung von dickem Baustahl deutlich.

AdjustLine ermöglicht eine einfache Anpassung des Schneidprozesses an unterschiedliche Materialgüten. Die Funktion erhöht die Prozesssicherheit, vor allem beim Schneiden von qualitativ schlechtem Material. Für Sie bedeutet das: weniger Ausschussteile bei geringeren Materialkosten. Der Bediener schaltet AdjustLine jederzeit ein oder aus – es ist keine Programmierung nötig.

Der Kollisionsschutz für Ihren Schneidkopf garantiert höchste Prozesssicherheit. Sie profitieren von kürzeren Nebenzeiten durch eine erhöhte Maschinenverfügbarkeit. Im Fall von Kollisionen werden Beschädigungen am Schneidkopf vermieden.

Die Funktion Dot Matrix Code ermöglicht Ihnen die schnelle und prozesssichere Teilekennzeichnung mit einem standardisierten Industriecode. Innerhalb weniger Sekunden trägt der Laser Ihrer Flachbettmaschine einen 2D-Code (DataMatrix) aus Punkten auf ein Teil auf. Er beinhaltet Informationen für die Prozesskette. Der Code dient etwa zum Aufrufen des passenden Programms an der nächsten Maschine.

Mit der MobileControl App bedienen und kontrollieren Sie Ihre Maschinen einfach und flexibel, denn die App überträgt die Oberfläche des Standardbedienpults auf den Touchscreen Ihres Tablets. Die App ermöglicht Ihnen, an unterschiedlichen Orten im Arbeitsumfeld der Maschine, zum Beispiel dem Abräumplatz, Maschineninformationen abzurufen oder Programmwechsel vorzunehmen.

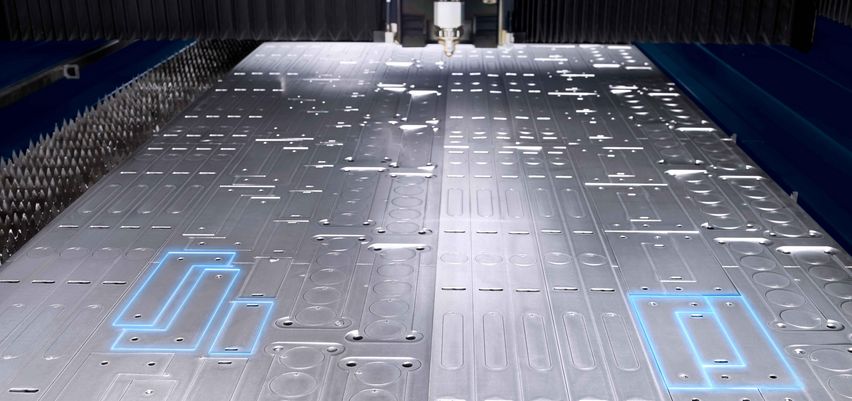

Mit Drop&Cut nutzen Sie Resttafeln einfach, intuitiv und effizient aus. Dank einer Kamera erscheint das Live-Bild des Maschineninnenraums direkt auf Ihrer Bedienoberfläche. Sie platzieren beliebig viele Teilegeometrien auf der Resttafel. Das spart viel Zeit beim Nachproduzieren einzelner Teile. Aufwendige Prozessschritte wie das Ausrichten des Blechs, die Blechlagevermessung oder die Nullpunkt-Verschiebung entfallen.

Der Sorting Guide ist ein kamerabasiertes Assistenzsystem, das den Werker beim Entnehmen und Sortieren von Blechteilen unterstützt. Er markiert Teile farblich nach Kundenauftrag oder Folgeprozess. So kann der Werker die geschnittenen Teile einfach, schnell und fehlerfrei auf Paletten kommissionieren.

Autonomer fertigen und Stillstände vermeiden: Mit Smart Rerun setzt Ihre Maschine die Produktion nach einer leichten Kollision oder einem Fehlschnitt selbstständig fort. Um Ausschuss zu vermeiden, liegt der Fokus immer auf dem Wiedereinstieg innerhalb der Kontur. Nur wenn dies nicht möglich ist, erfolgt der Sprung zum nächsten Teil. Immer mit dem Ziel, dass die Produktion weiterläuft.

Die nahtlose Integration vieler Maschinen von TRUMPF in die eigene Softwarewelt ist problemlos und einfach. Sei es eine Integration in Oseon oder eine Anbindung an Monitoring und Analyse Tools - für jede Kombination stellen wir die passende Lösung bereit. Auch eine Anbindung an Software Systeme von Drittanbietern ist mit unseren Schnittstellen basierend auf dem OPC UA Standard möglich.

Saubere Schutzgläser halten Ihre Schnittqualität auf langfristig hohem Niveau. Damit Sie wissen, wann Sie die Schutzgläser tauschen müssen, überwacht ein Sensor den Schutzglaszustand dauerhaft. Reinigung und Tausch erfolgen kostensparend nur im Bedarfsfall.

Flexibilität

Die Funktion EdgeLine Bevel kann jetzt noch mehr: Schneiden Sie damit sowohl Fasen sowie Senkungen und verrunden Sie Kanten direkt auf Ihrer Laserschneidmaschine. So reduzieren Sie Ihren Aufwand an zusätzlichen Prozessschritten und vermeiden scharfkantige Bleche. Die einfache und schnelle Programmierung von EdgeLine Bevel unterstützt Ihre Anwendungsvielfalt. Das heißt konkret: Sie bearbeiten Fasen mit unterschiedlichen Winkeln und Senkungen in mehreren Größen. Zudem steigern abgerundete Kanten die optische Güte Ihrer Bauteile und senken das Risiko von Schnittverletzungen.

Autonomie

Das System blickt während des Schneidens durch die Düse in den Schnittspalt, überwacht den Schneidprozess und regelt selbstständig die Vorschubgeschwindigkeit. Selbst wenn die Blechdicke innerhalb einer Tafel variiert oder Qualitätsschwankungen wie Rost und Lackreste das Blech beeinflusst haben, stellt die Sensorik den richtigen Vorschub beim Brenn- und Schmelzschnitt sicher. Die Datenanalyse ermöglicht einen stabilen und schnellen Schnitt. Schneidunterbrechungen können so vermieden werden, was den Teileausschuss deutlich reduziert. Auch der Bediener wird entlastet. Er kann jederzeit die wichtigsten Prozessparameter sowie ein Live-Bild durch die Düse abrufen und wird aktiv informiert, falls ein Eingreifen erforderlich ist.

Der optimale Zustand von Düse und Linse ist eine wichtige Voraussetzung für optimale Prozesssicherheit und Teilequalität. Smart Nozzle Automation kombiniert intelligente Funktionen, unter anderem LensLine zur Erhöhung der Lebensdauer Ihrer Linse, die genau das gewährleisten – auch im vollautomatischen Betrieb. Selbstständig erkennt und behebt die Funktion viele Ursachen, die das Schneidergebnis beeinträchtigen können; Reinigungs- und Austauschzyklen der Düse können Sie viel besser planen.

Die Funktion zur Vermeidung von Kollisionen erhalten Sie jetzt in zwei verschiedenen Modi. Ob Tafelmodus oder Einzelteilmodus: Auf den Einsatz von Microjoints können Sie weitestgehend verzichten. Das spart aufwendige Nacharbeit. Auch das automatisierte Entladen der Teile ist möglich, da diese nicht kippen.

Ein Kamerasystem bestimmt die Lage eingelegter Bleche präzise und ermöglicht die hochgenaue Nacharbeit bereits geschnittener Teile. Außerdem vermisst DetectLine einen geschnittenen Fokuskamm automatisch und stellt die Fokuslage ein.

Produktivität

Schnell und sparsam – ohne Abstriche bei der Qualität: Mit Highspeed stellen Sie beim Stickstoff-Schneiden mit dem Festkörperlaser Rekorde auf. So können Sie Ihren Tafeldurchsatz bei mittleren und dicken Baustahl- und Edelstahlblechen nahezu verdoppeln. Auch bei der Vorschubgeschwindigkeit ist eine Verdopplung möglich. Ein besonderes Düsendesign reduziert Ihren Schneidgasverbrauch außerdem um bis zu 40 % und beugt bei scharfkantigen Konturen sogar der Gratbildung vor. Der Prozess erschließt außerdem neue Blechdicken für die Bearbeitung mit Stickstoff. In Verbindung mit dem TruDisk 8001 schneidet die TruLaser 5030 fiber Baustahl mit einer Stärke von 12 mm.

Extrem schnell, extrem sparsam: Mit diesem Highspeed-Prozess reduzieren Sie Ihren Schneidgasverbrauch beim Stickstoff-Schneiden um bis zu 70 %. Das ermöglicht ein patentiertes Düsendesign. Gleichzeitig können Sie mit Highspeed Eco Ihren Tafeldurchsatz bei mittleren und dicken Baustahl- und Edelstahlblechen nahezu verdoppeln und steigern die Vorschubgeschwindigkeit um bis zu 100 %. Die Qualität leidet dabei nicht. Highspeed Eco verhindert bei scharfkantigen Konturen sogar die Gratbildung. Der Prozess erschließt zusätzlich neue Blechdicken für die Bearbeitung mit Stickstoff. In Verbindung mit dem TruDisk 8001 schneidet die TruLaser 5030 fiber Baustahl mit einer Stärke von 12 mm.

Der neue TruDisk 24001 verdoppelt mit satten 24 kW die Laserleistung der TruLaser Serie 5000. Damit bearbeiten die Laserschneidmaschinen Bauteile bis zu dreimal so schnell und erhöhen den Tafeldurchsatz um bis zu 80 % pro Stunde, je nach Material. Sie möchten Produktivität und Teilequalität Ihrer Fertigung weiter steigern? Dann profitieren Sie mit Sicherheit von den 24 kW Laserleistung dieses Lasers. Vor allem Bauteile in mittleren oder hohen Blechdicken fertigen Sie damit über alle Materialien hinweg effizient. Zudem verbessern Sie – dank der doppelten Laserleistung – die Qualität Ihrer geschnittenen Teile.

Qualität

BrightLine fiber macht den Festkörperlaser zum Universalwerkzeug: Die Funktion ermöglicht Ihnen hochwertige Schneidergebnisse über den gesamten Blechdickenbereich hinweg. Zudem bleiben sämtliche Vorteile des Festkörperlasers bei der Dünnblechbearbeitung, insbesondere die hohen Geschwindigkeiten, erhalten.

Mit PierceLine wird der Einstechvorgang überwacht und geregelt. Das schont sowohl Material als auch Maschine, erhöht die Teilequalität und verkürzt die Einstechzeit um bis zu 80 %.

Die innovativen Performance Düsen und die optimierten Schneiddaten des Performance-Pakets ermöglichen Ihnen beim Schmelzschmitt in Dünnblech gleich zwei große Schritte nach vorne: einen Qualitätssprung und eine deutlich höhere Produktivität.

Der integrierte Gasmischer kombiniert die Schneidgase Stickstoff und Sauerstoff miteinander – automatisch und ganz ohne Bedienerbindung. Der Einsatz eines Gasgemisches in Verbindung mit hoher Laserleistung verbessert die Teilequalität im Baustahl und Aluminium. In Abhängigkeit der Materialart, Materiallegierung und Materialqualität kann der Grat des lasergeschnittenen Bauteils reduziert werden.

Hohe Materialtoleranz, stabiler Prozess: Mit FlexLine erzielen Sie bestmögliche Schneidergebnisse in Baustahl unterschiedlicher Güte. Dank patentiertem Düsendesign und spezieller Schneidparameter schneiden Sie filigrane Konturen selbst in hohen Blechdicken sicher. So bleiben Sie flexibel und nutzen Ihr Material optimal aus.

TruTops Boost

Konstruieren und programmieren Sie Ihre 2D-Laser-, Stanz- und kombinierten Stanz-Laser-Maschinen intelligent mit TruTops Boost, Ihre All-in-One-3D-Lösung. Viele Automatismen ersparen Ihnen zeitaufwendige Routinevorgänge und der gemeinsame Schachtelpool spart Zeit und Material. Außerdem behalten Sie stets den Überblick über alle Fertigungsaufträge und auftragsorientiertes Arbeiten.

Software

Von der Kundenanfrage bis zur Auslieferung des gefertigten Teils – das Software-Portfolio von TRUMPF optimiert Ihren kompletten Fertigungsprozess. TRUMPF kombiniert dabei die Software intelligent mit Maschinen und Services zu maßgeschneiderten Industrie 4.0-Lösungen für Ihre Smart Factory.

Aus einem großen Baukasten wählen Sie die richtigen Automatisierungskomponenten für Ihre Laserschneidemaschine. Vom halbautomatischen Beladen bis hin zur vollautomatischen Fertigungszelle mit Lageranbindung bietet TRUMPF Lösungen an, die Ihre Prozesskette optimieren.

Beladen

Ihr Einstieg in die Automatisierung: Der LoadMaster ermöglicht das automatische Beladen Ihrer Maschine mit Rohblechen.

Be- und Entladen

LiftMaster Compact be- und entlädt Ihre Maschine vollautomatisch. Die Auslastung von bis zu zwei Maschinen erhöht der LiftMaster Linear Basic

Be- und Entladen / Teilesortierung

Die Automatisierungslösung LiftMaster deckte eine große Bandbreite von Automatisierungsfunktionen ab. Sie be- und entlädt, eignet sich aber auch für die Palettenhandhabe oder Teileentnahme. Der LiftMaster Sort trennt darüber hinaus Fertigteile vom Restgitter. LiftMaster Store und LiftMaster Store Linear binden Ihre Anlage direkt ans Lager an. Der SortMaster sortiert vollautomatisch Fertigteile.

Lagersystem

Mit den Lagersystemen der TruStore Serie 1000 und TruStore Serie 3000 organisieren Sie Ihr Materialhandling anhand Ihrer Bedürfnisse.

Je nach Land sind Abweichungen von diesem Produktsortiment und von diesen Angaben möglich. Änderungen in Technik, Ausstattung, Preis und Zubehörangebot sind vorbehalten. Bitte setzen Sie sich mit Ihrem Ansprechpartner vor Ort in Verbindung, um zu erfahren, ob das Produkt in Ihrem Land verfügbar ist.

Fußnoten-

Entspricht dem Maschinengewicht mit Standardausstattung. Das Gewicht kann je nach Ausstattung variieren.

-

Das maximale Werkstückgewicht auf beiden Paletten ist identisch. Es gibt allerdings unterschiedliche Verteilungen des Werkstückgewichtes auf den Paletten. Ohne Schwerlastpalettenwechsler Verteilung max. 30 mm / 30 mm Blechdicke je Palette und Format. Mit Schwerlastpalettenwechsler Verteilung max. 50 mm / 10 mm Blechdicke je Palette und Format.