Nothing comes close to experiencing a laser for yourself, in your own system! We are happy to advise you concerning your application requirements and will consider together how a test laser can help you. We make it possible for you to test a suitable TRUMPF laser at your site and in your system – for up to 30 days.

Versatility for a wide range of applications

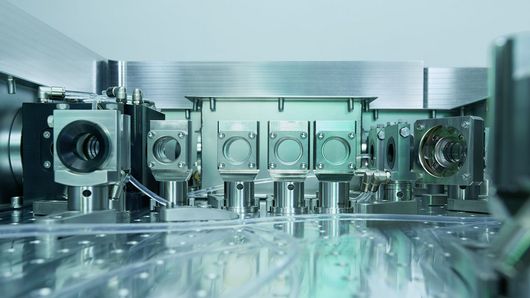

Our pulsed TRUMPF TruPulse nano fiber lasers with GTWave and PulseTune technology are some of the most versatile industrial lasers in the TRUMPF portfolio. These lasers operate within the nanosecond pulse duration range and are used in a multitude of industrial applications. They offer users unmatched flexibility. As they are also maintenance-free, you can concentrate on the result instead of on time-consuming and costly maintenance plans.

Use a non-contact procedure to create permanent markings at high speed and with a high level of precision. In addition, laser markings do not require any consumable materials; they are computer-generated and therefore offer maximum flexibility.

Reach the heights of pulsed nanosecond technology with extended functions for microprocessing which elevate our PulseTune-compatible lasers to a new level. These lasers provide OEM integrators with highly flexible control of the pulse range and peak power. The unique PulseTune function enables market-leading pulse repetition frequencies while simultaneously maintaining peak power.

Select from up to 48 available wave forms. You increase your process quality and productivity as the central pulse features can be perfectly optimized for individual applications.

The pulsed fiber lasers operate maintenance-free. This means you can concentrate on the result at all times – time-consuming maintenance plans are a thing of the past.

Welding in nanoseconds

Regardless of the material, thickness or combination of different metals, our lasers offer the versatility of welding a variety of products – from fuel cells and batteries to fine wires for manufacturing medical equipment. You can join practically any combination of thin metallic components with our patented nanosecond welding procedure. This includes highly reflective and conductive metals as well.

Drilling

In the case of laser drilling, a laser beam is repeatedly pulsed onto a certain area. The material to be drilled is evaporated and melted layer-by-layer until this creates drilled holes. Drilling with lasers is characterized by a high degree of precision which can be carefully controlled by monitoring the beam intensity and duration.

Cutting

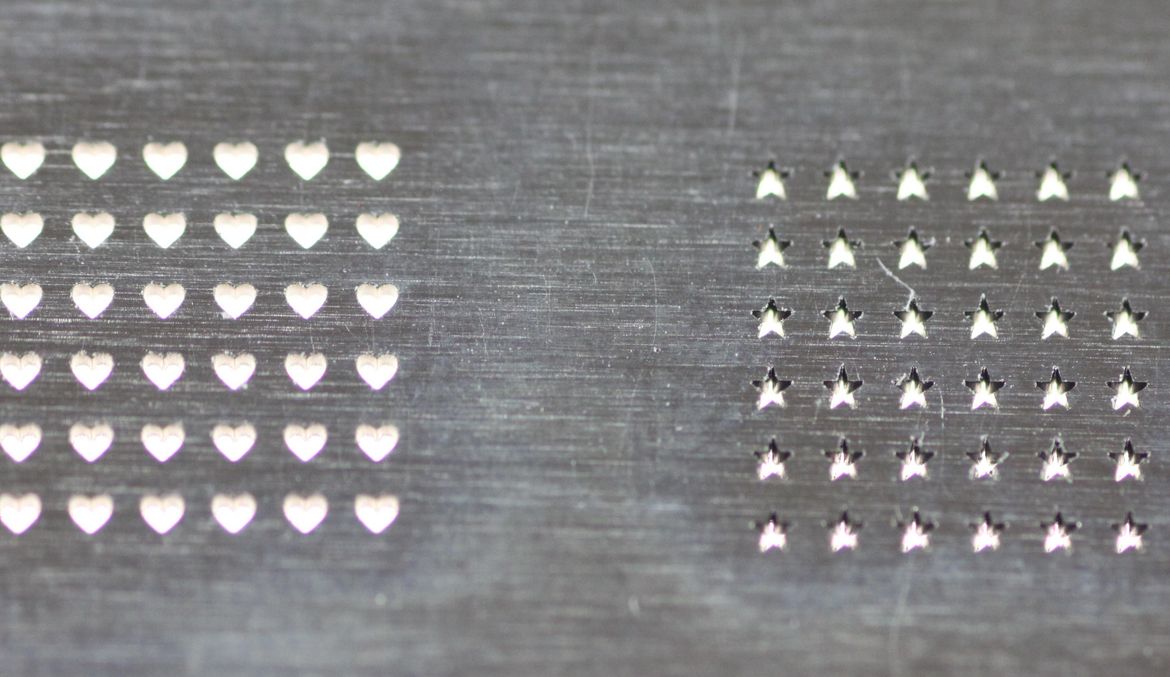

The laser beam can be easily programmed so that it can cut a variety of thicknesses and materials with precision. This includes metals including reflective metals such as copper, silver and aluminum, as well as brass, tungsten, steel, tin and titanium. Gems such as diamonds, or ceramic, graphic compound materials, silicon and many types of plastic can also be processed. Even very complex forms can be cut very precisely as the user always has full control of the beam intensity, duration and heat input.

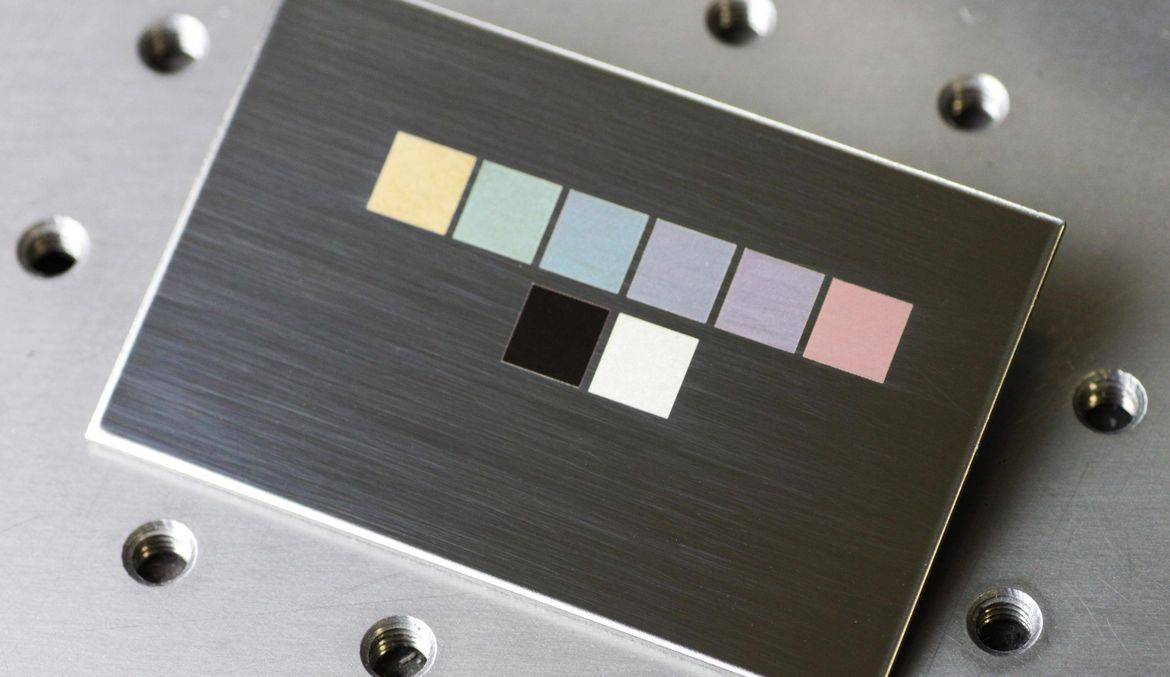

Marking and engraving

While a marking is simply on the surface of a workpiece, an engraving is an in-depth marking. Almost any material can be marked in black with the laser, and some materials can even be marked in color. Laser markings are used on ceramic, plastics, metals, LEDs, rubber and graphic compound materials, among others.

Coating ablation

The laser makes it possible to remove layers in metals or industrial connections with precision, for example, in semi-conductors and microprocessors in electronic products.

Cleaning

High pulse repetition frequencies and short pulse durations at high peak power are typical for cleaning lasers – perfect for pulsed short-pulse lasers. The objective is to remove surface residue and contaminated layers without damaging substrate materials in the process. Laser cleaning is a cost-efficient and environmentally friendly application that has been established in industries all over the world.

|

TruPulse 1002 nano (FK10-EP)

Compare product

|

TruPulse 1002 nano (FK10-HS)

Compare product

|

TruPulse 1003 nano (FK10-HS)

Compare product

|

TruPulse 1005 nano (FK10-HS)

Compare product

|

TruPulse 1010 nano (FK10-EP)

Compare product

|

TruPulse 2002 nano (FK10-EP)

Compare product

|

TruPulse 2002 nano (FK10-RM)

Compare product

|

TruPulse 2003 nano (FK10-RM)

Compare product

|

TruPulse 2005 nano (FK10-EP)

Compare product

|

TruPulse 2005 nano (FK10-RM)

Compare product

|

TruPulse 2007 nano (FK10-EP)

Compare product

|

TruPulse 2007 nano (FK10-RM)

Compare product

|

TruPulse 2010 nano (FK10-EP)

Compare product

|

TruPulse 2013 nano (FK10-EP)

Compare product

|

TruPulse 2020 nano (FK10-EP)

Compare product

|

TruPulse 2030 nano (FK10-EP)

Compare product

|

TruPulse 2060 nano (FK10-EP)

Compare product

|

TruPulse 3002 nano (FK10-EP)

Compare product

|

TruPulse 3002 nano (FK10-HS)

Compare product

|

TruPulse 4004 nano (FK10-HS)

Compare product

|

TruPulse 4007 nano (FK10-HS)

Compare product

|

TruPulse 5020 nano (FK10-EP)

Compare product

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Laser parameters | ||||||||||||||||||||||

| Average output power | 20 W | 20 W | 30 W | 50 W | 100 W | 20 W | 20 W | 30 W | 50 W | 50 W | 70 W | 70 W | 100 W | 130 W | 200 W | 300 W | 600 W | 20 W | 20 W | 40 W | 70 W | 200 W |

| Maximum peak pulse power | > 7 kW | > 7 kW | > 7 kW | > 7 kW | > 7 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 8 kW | > 10 kW | > 12 kW | > 12 kW | > 20 kW | > 20 kW | > 50 kW |

| Beam quality (M²) | < 1.3 | < 1.3 | < 1.3 | < 1.3 | < 1.3 | < 1.6 | < 1.6 | < 1.6 | < 1.6 | < 1.6 | < 1.6 | < 1.6 | < 1.6 | < 1.6 | < 1.6 | < 1.6 | < 1.6 | < 1.8 | 1.8 | 2.5 - 3.5 | 3 | < 5 |

| Wavelength spectrum | 1059 nm - 1065 nm | 1059 nm - 1065 nm | 1059 nm - 1065 nm | 1059 nm - 1065 nm | 1060 nm - 1070 nm | 1059 nm - 1065 nm | ||||||||||||||||

| Maximum pulse energy | > 0.8 mJ | > 0.6 mJ | > 0.6 mJ | > 0.6 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1.3 mJ | > 1.5 mJ | > 1.5 mJ | > 1.5 mJ | > 2.1 mJ | > 1 mJ | > 0.8 mJ | > 1.3 mJ | > 1.25 mJ | > 5 mJ |

| Pulse duration range | 3 ns - 2000 ns | 10 ns - 240 ns | 10 ns - 240 ns | 11 ns - 220 ns | 4 ns - 2000 ns | 3 ns - 500 ns | 26 ns - 250 ns | 26 ns - 250 ns | 6 ns - 500 ns | 26 ns - 250 ns | 9 ns - 500 ns | 28 ns - 260 ns | 4 ns - 2000 ns | 3 ns - 2000 ns | 9 ns - 2000 ns | 12 ns - 1200 ns | 20 ns - 800 ns | 10 ns - 220 ns | 2 ns - 500 ns | 10 ns - 240 ns | 10 ns - 250 ns | 12 ns - 2000 ns |

| Pulse repetition frequency | 1 kHz - 4000 kHz | 1 kHz - 1000 kHz | 1 kHz - 1000 kHz | 1 kHz - 1000 kHz | 1 kHz - 4000 kHz | 1 kHz - 1000 kHz | 1 kHz - 500 kHz | 1 kHz - 500 kHz | 1 kHz - 1000 kHz | 1 kHz - 500 kHz | 1 kHz - 1000 kHz | 1 kHz - 500 kHz | 1 kHz - 4000 kHz | 1 kHz - 4000 kHz | 1 kHz - 4000 kHz | 1 kHz - 4000 kHz | Up to 4166 kHz | 1 kHz - 1000 kHz | 1 kHz - 1000 kHz | 1 kHz - 1000 kHz | 1 kHz - 1000 kHz | 1 kHz - 4000 kHz |

| Wavelength | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | ||||||

| Structural design | ||||||||||||||||||||||

| Dimensions (W x H x D) | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 377 mm x 249 mm x 115 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 377 mm x 249 mm x 95 mm | 377 mm x 249 mm x 95 mm | 377 mm x 249 mm x 115 mm | 423 mm x 417 mm x 133 mm | 423 mm x 417 mm x 133 mm | 447 mm x 417 mm x 88 mm | 622 mm x 482 mm x 177 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 377 mm x 249 mm x 95 mm | 473 mm x 417 mm x 133 mm |

| Installation | ||||||||||||||||||||||

| Ambient temperature | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 42 °C | 5 °C - 40 °C | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 40 °C | 0 °C - 40 °C | 0 °C - 40 °C | 0 °C - 40 °C | 0 °C - 40 °C | 10 °C - 45 °C | 10 °C - 40 °C | 15 °C - 38 °C | 15 °C - 40 °C | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 40 °C | 10 °C - 40 °C |

|

TruPulse 1002 nano (FK10-EP)

|

TruPulse 1002 nano (FK10-HS)

|

TruPulse 1003 nano (FK10-HS)

|

TruPulse 1005 nano (FK10-HS)

|

TruPulse 1010 nano (FK10-EP)

|

TruPulse 2002 nano (FK10-EP)

|

TruPulse 2002 nano (FK10-RM)

|

TruPulse 2003 nano (FK10-RM)

|

TruPulse 2005 nano (FK10-EP)

|

TruPulse 2005 nano (FK10-RM)

|

TruPulse 2007 nano (FK10-EP)

|

TruPulse 2007 nano (FK10-RM)

|

TruPulse 2010 nano (FK10-EP)

|

TruPulse 2013 nano (FK10-EP)

|

TruPulse 2020 nano (FK10-EP)

|

TruPulse 2030 nano (FK10-EP)

|

TruPulse 2060 nano (FK10-EP)

|

TruPulse 3002 nano (FK10-EP)

|

TruPulse 3002 nano (FK10-HS)

|

TruPulse 4004 nano (FK10-HS)

|

TruPulse 4007 nano (FK10-HS)

|

TruPulse 5020 nano (FK10-EP)

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Laser parameters | ||||||||||||||||||||||

| Average output power | 20 W | 20 W | 30 W | 50 W | 100 W | 20 W | 20 W | 30 W | 50 W | 50 W | 70 W | 70 W | 100 W | 130 W | 200 W | 300 W | 600 W | 20 W | 20 W | 40 W | 70 W | 200 W |

| Maximum peak pulse power | > 7 kW | > 7 kW | > 7 kW | > 7 kW | > 7 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 8 kW | > 10 kW | > 12 kW | > 12 kW | > 20 kW | > 20 kW | > 50 kW |

| Beam quality (M²) | < 1.3 | < 1.3 | < 1.3 | < 1.3 | < 1.3 | < 1.6 | < 1.6 | < 1.6 | < 1.6 | < 1.6 | < 1.6 | < 1.6 | < 1.6 | < 1.6 | < 1.6 | < 1.6 | < 1.6 | < 1.8 | 1.8 | 2.5 - 3.5 | 3 | < 5 |

| Wavelength spectrum | 1059 nm - 1065 nm | 1059 nm - 1065 nm | 1059 nm - 1065 nm | 1059 nm - 1065 nm | 1060 nm - 1070 nm | 1059 nm - 1065 nm | ||||||||||||||||

| Maximum pulse energy | > 0.8 mJ | > 0.6 mJ | > 0.6 mJ | > 0.6 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1.3 mJ | > 1.5 mJ | > 1.5 mJ | > 1.5 mJ | > 2.1 mJ | > 1 mJ | > 0.8 mJ | > 1.3 mJ | > 1.25 mJ | > 5 mJ |

| Pulse duration range | 3 ns - 2000 ns | 10 ns - 240 ns | 10 ns - 240 ns | 11 ns - 220 ns | 4 ns - 2000 ns | 3 ns - 500 ns | 26 ns - 250 ns | 26 ns - 250 ns | 6 ns - 500 ns | 26 ns - 250 ns | 9 ns - 500 ns | 28 ns - 260 ns | 4 ns - 2000 ns | 3 ns - 2000 ns | 9 ns - 2000 ns | 12 ns - 1200 ns | 20 ns - 800 ns | 10 ns - 220 ns | 2 ns - 500 ns | 10 ns - 240 ns | 10 ns - 250 ns | 12 ns - 2000 ns |

| Pulse repetition frequency | 1 kHz - 4000 kHz | 1 kHz - 1000 kHz | 1 kHz - 1000 kHz | 1 kHz - 1000 kHz | 1 kHz - 4000 kHz | 1 kHz - 1000 kHz | 1 kHz - 500 kHz | 1 kHz - 500 kHz | 1 kHz - 1000 kHz | 1 kHz - 500 kHz | 1 kHz - 1000 kHz | 1 kHz - 500 kHz | 1 kHz - 4000 kHz | 1 kHz - 4000 kHz | 1 kHz - 4000 kHz | 1 kHz - 4000 kHz | Up to 4166 kHz | 1 kHz - 1000 kHz | 1 kHz - 1000 kHz | 1 kHz - 1000 kHz | 1 kHz - 1000 kHz | 1 kHz - 4000 kHz |

| Wavelength | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | ||||||

| Structural design | ||||||||||||||||||||||

| Dimensions (W x H x D) | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 377 mm x 249 mm x 115 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 377 mm x 249 mm x 95 mm | 377 mm x 249 mm x 95 mm | 377 mm x 249 mm x 115 mm | 423 mm x 417 mm x 133 mm | 423 mm x 417 mm x 133 mm | 447 mm x 417 mm x 88 mm | 622 mm x 482 mm x 177 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 377 mm x 249 mm x 95 mm | 473 mm x 417 mm x 133 mm |

| Installation | ||||||||||||||||||||||

| Ambient temperature | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 42 °C | 5 °C - 40 °C | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 40 °C | 0 °C - 40 °C | 0 °C - 40 °C | 0 °C - 40 °C | 0 °C - 40 °C | 10 °C - 45 °C | 10 °C - 40 °C | 15 °C - 38 °C | 15 °C - 40 °C | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 40 °C | 10 °C - 40 °C |

The technical data of all product versions as a download.

No maintenance required

TruPulse nano fiber lasers represent a truly "fit and forget" technology with no maintenance requirements through their operating life, meaning lower operating costs.

More flexibility thanks to pulse control functionality

The TruPulse nano range benefits from TRUMPF's PulseTune functionality that provides users with the widest range of pulse durations from 3 ns to 2 µs. This gives unrivaled flexibility in process optimization that can yield improvements in productivity and/or process quality.

High reliability and three year warranty

Designed for 24/7 operation these lasers offer industry leading reliability that is underpinned by our standard 3 year warranty. They benefit from a robust beam delivery cable, ethernet connectivity, field replaceable electronics and come CE marked to facilitate system integration.

Simple integration

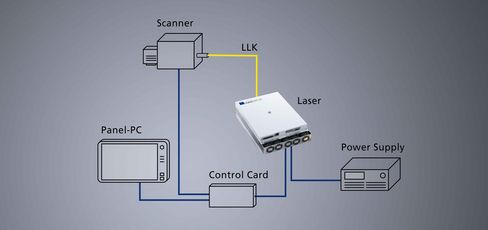

TruPulse nano lasers are modules for integration and as such are typically used with galvo scanners and their associated control hardware and software. TruPulse nano has an industry standard interface that can be readily integrated with many available third-party scanner control cards and their related software packages.

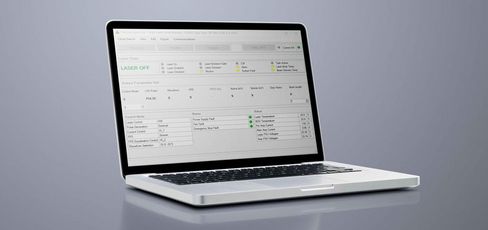

User interface for laser monitoring and diagnostics

A Graphical User Interface (GUI) is available for use with the full range of TruPulse nano products. This GUI provides users with an array of tools and features that enable laser control and monitoring. This software is primarily used to aid integration and for service and diagnostics.

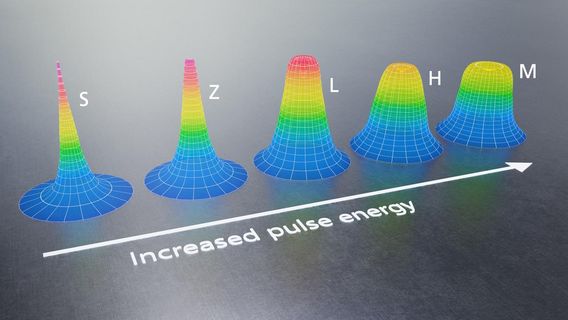

Series 1000 | S-type (single mode M2 <1.3): provides a very fine spot size (<20 micrometers) with high performance stability and great depth of focus. Ideal for applications requiring small structure sizes.

Series 2000 | Z-type (M2 <1.6): provides higher peak power and pulse energy with only a slight increase in spot size and good depth of focus.

Series 3000 | L-type (low mode M2 1.6 - 2.0): for general marking applications with somewhat larger spots and features. Markings can be detected with the naked eye.

Series 4000 | H-type (high mode M2 2.5 - 3.5): provides high pulse energies, peak power and even larger spots, ideal for wide lines, applications with filled fonts and a high area coverage.

Series 5000 | M-type – multimode (M2 4.0 - 6.0): highest pulse energies and longer pulse durations, perfect for welding and cleaning.

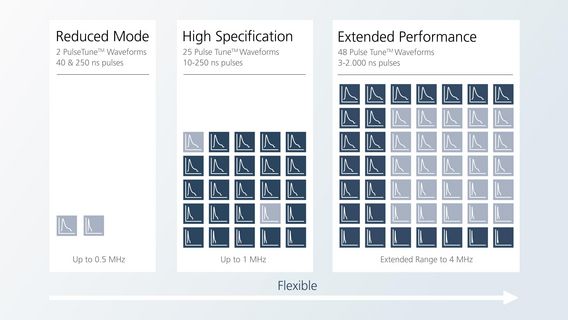

Depending on requirements, you can choose between several products within our PulseTune waveform options.

- The entry-level products of the RM range (Reduced Mode) have limited pulse operation as well as basic software and hardware interfaces. You can utilize two PulseTune wave forms in these models and operate with a limited pulse repetition frequency of up to 500 kHz.

- With the models of the HS range (High Specification), you benefit from our PulseTune technology and a pulse duration which can be selected variably with 25 preset wave forms. Thanks to improved control and modulated CW functionality, you will work with even greater precision. The pulse repetition frequency is up to 1 MHz.

- You can choose between up to 48 optimized PulseTune wave forms in the EP range (Extended Performance). With this range, we are offering you our most versatile fiber laser source with improved control and modulated CW functionality. Furthermore, the pulse energy and peak power have been increased again. The pulse duration range is from 3-2000 ns, the pulse repetition frequency is up to 4 MHz.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

Experience it for yourself: request your test laser now!