Electronics

Faster, smaller, more efficient: Progress in micro-electronics is closely linked to laser technology.

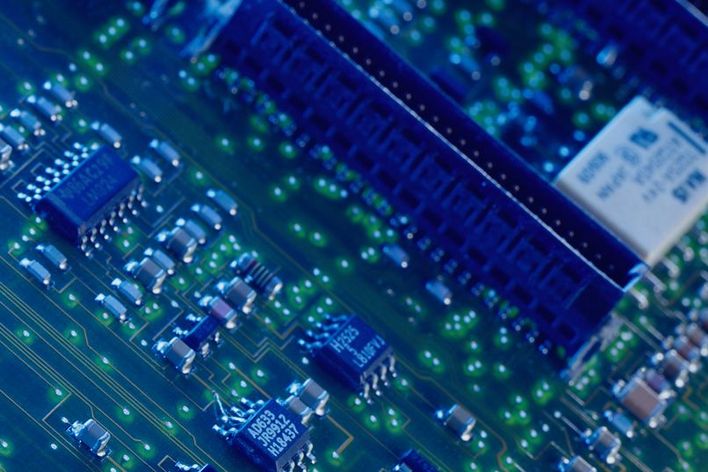

A continuous trend toward miniaturization and extremely large quantities are two of the most important characteristics of the electronics industry. As a result of unprecedented precision and good automation potential, laser technology can provide industrial solutions to these challenges. TRUMPF lasers play a fundamental role in the production of the latest generation of computer chips. Lasers also enable a large number of other process steps to be carried out, such as cutting and drilling silicon wafers, printed circuit boards, or entire electronics modules. TRUMPF Hüttinger generators also provide reliable and precise process energy for coating and etching processes in the production of silicon wafers.

Semi-conductor industry

TRUMPF lasers produce very high quantities of reproducible and high-quality products that are predestined for the electronics industry. More than 1,000 ultrashort pulse lasers from TRUMPF work in the production facilities of global industry leaders around the clock, 365 days a year. TRUMPF provides a machine solution or an individual laser technology package depending on the area of application. In both cases, customers benefit from the TRUMPF Group's international service network.

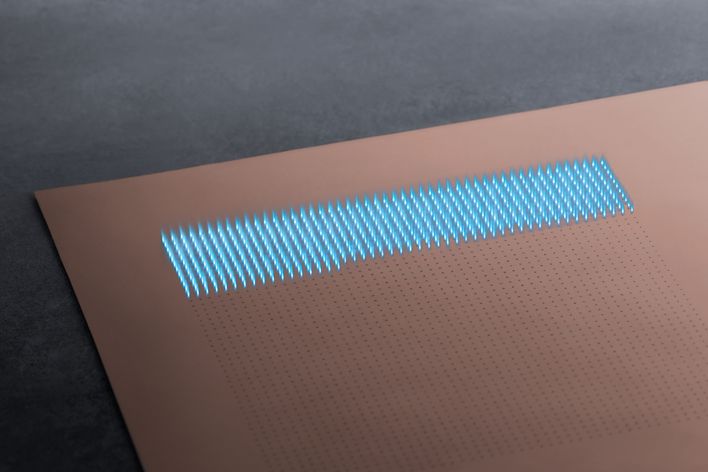

High-performance chips of the future

The development of micro-electronics, and therefore the basis of today's computers and smartphones, would be inconceivable without laser technology. Logic and storage chips have structures in the nanometer range and can only be produced using complex exposure processes with laser radiation. The conventional approach with UV laser radiation from excimer lasers is increasingly reaching its limits. In the future, it will only be possible to generate smaller structures with even shorter wavelengths in the extreme ultraviolet range (EUV). Together with the largest manufacturer of lithography systems ASML and the optics specialist Zeiss, TRUMPF has a long and intensive cooperation on this process of EUV lithography and developed a globally unique CO2 laser system. In the future, therefore, a little bit of TRUMPF technology will make its way into many high-performance chips.

Manufacturing chips

The plasma generators from TRUMPF Hüttinger also play a fundamental role in manufacturing chips. The quality of the power supply dictates the quality and precision of the plasma generated. This plasma is used in the next step for doping (ion implantation), deposition (PECVD, ALD) or removal (plasma etching) of different materials for the production of semiconductor chips. During this process, toxic environmental gases are generated which are effectively cleaned by a special system in the TRUMPF Hüttinger generators, thus the emission of environmentally harmful greenhouse gases in semiconductor production as low as possible.

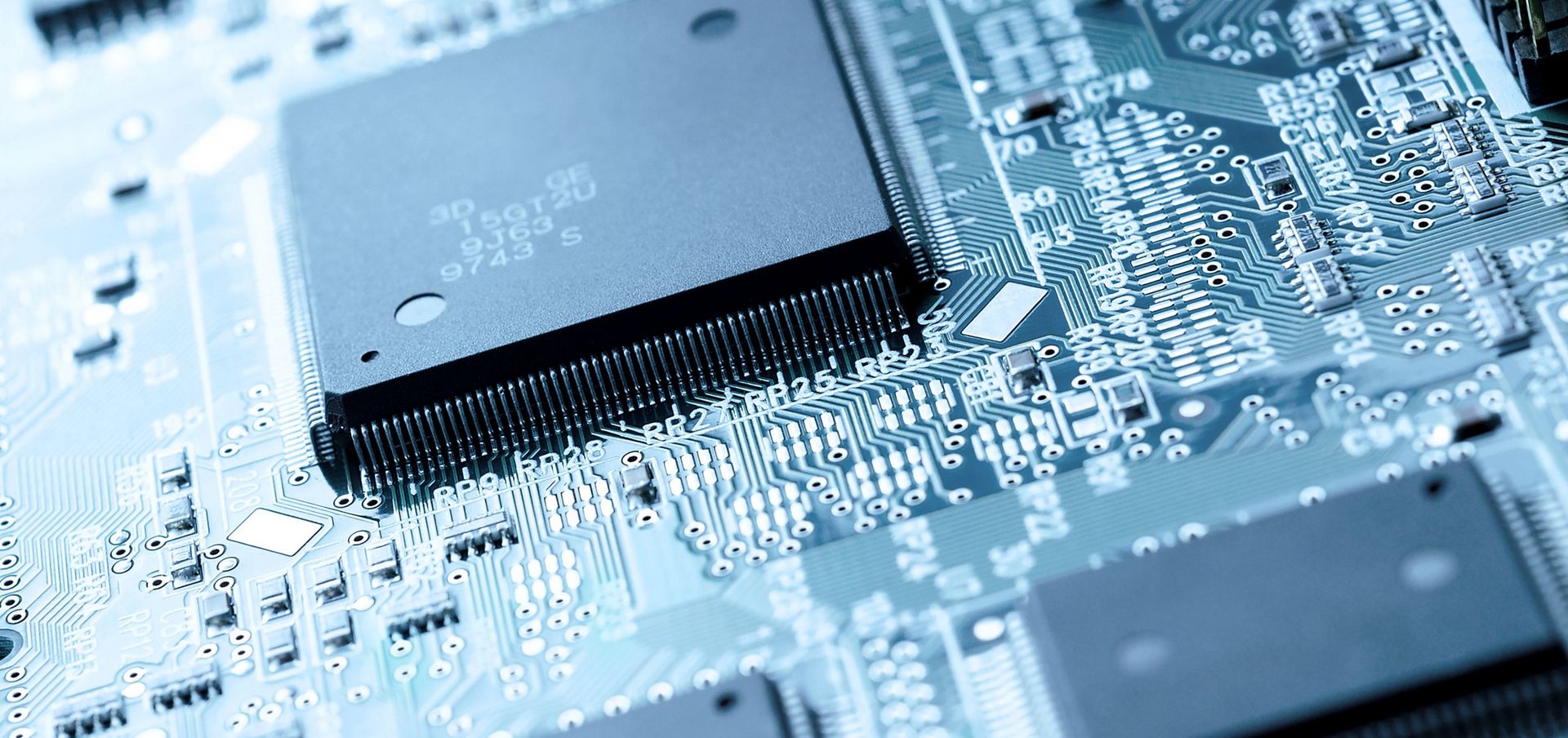

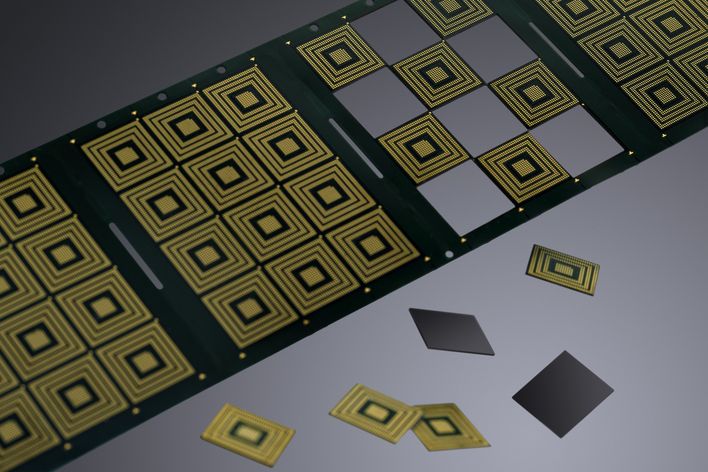

Cold precision processing of chips, packages, and printed circuit boards

After exposure and the construction of the circuits on the silicon wafers, the separation into separate chips is the next challenge for the electronic process chain. In order to achieve the smallest possible kerfs and a high edge quality, and to avoid damaging the sensitive chips due to thermal influences, ultrashort pulse lasers from TRUMPF are used for separation. These enable the material to be processed without unwanted heat influence, and the highest precision as part of the laser processing. These lasers are also suitable for trimming sensitive modules (system-in-package), processing multi-material printed circuit boards, and drilling so-called microvias in silicon and glass. The industry also uses TRUMPF lasers for targeted layer ablation, for cutting films, and for marking.

Crystal growing

The synthetic production of crystals forms the basis for the production of semi-conductors – and therefore, the basis for all communication and media technology. For this, single-crystalline layers grow on a single-crystalline substrate of the same material, which retains the crystallographic order. This process is used for the production of LEDs, among other applications. TRUMPF Hüttinger induction generators distribute temperature in a homogeneous and stable manner due to fast and precise control of the output values.