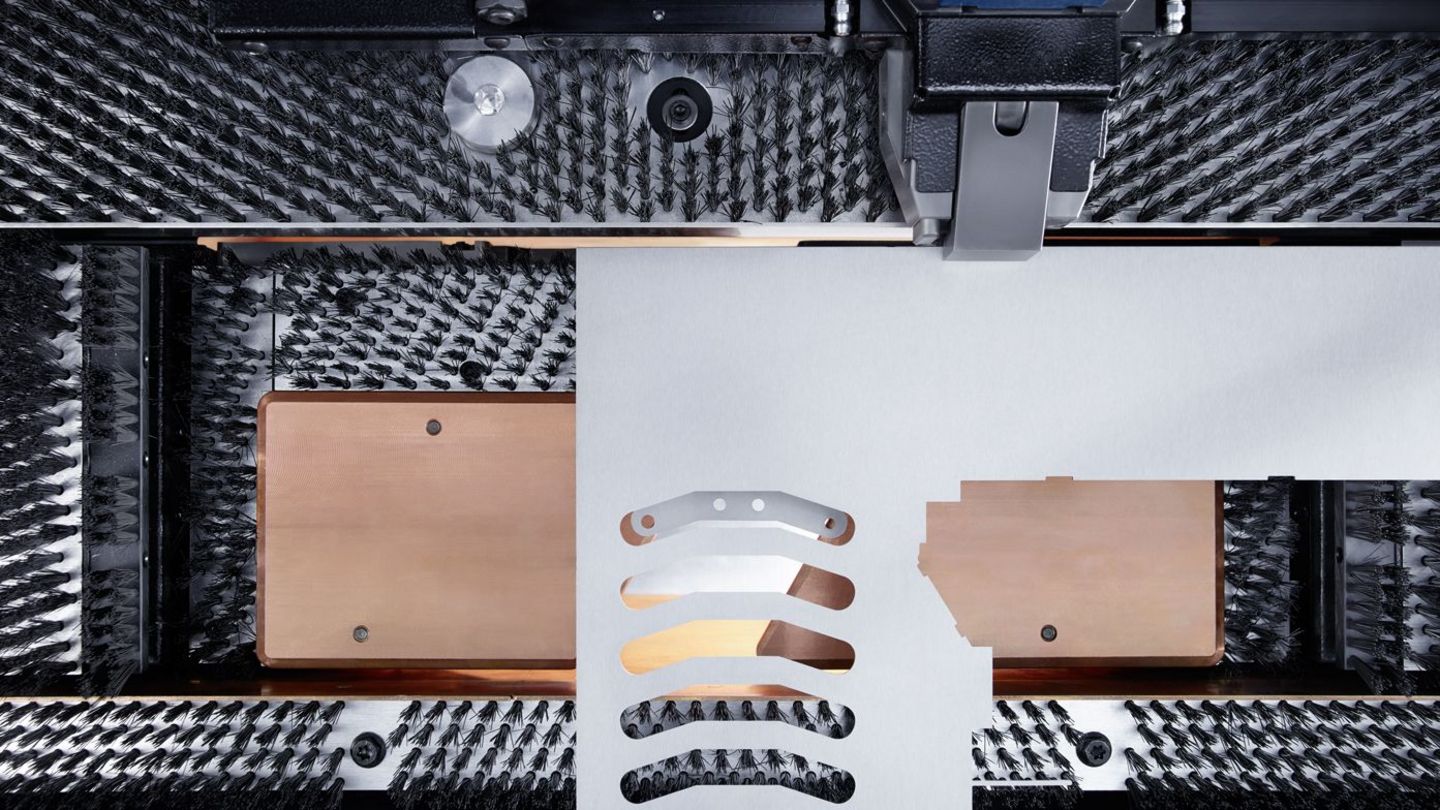

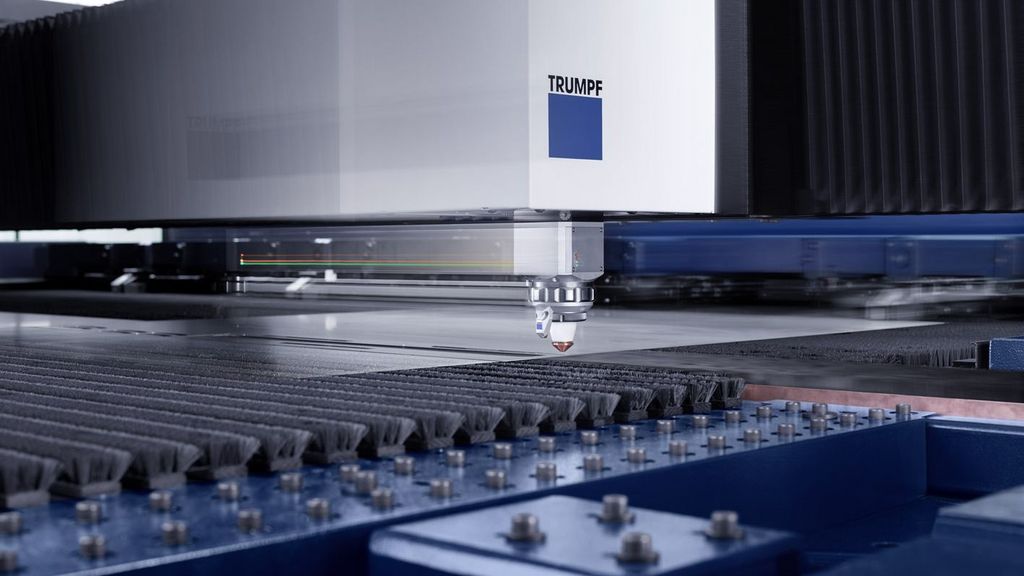

In contrast to traditional 2D laser processing machines, on the TruLaser Center 7030 both the cutting head and the sheet metal move. The additional axis on the cutting head enables the machine to achieve first-rate cutting dynamics. This means that you can cut corners and complex contours at high speeds. This highly dynamic combination makes full use of the high feed rates of the solid-state laser.

The TruLaser Center 7030 – leaves behind the fundamental principle of laser processing

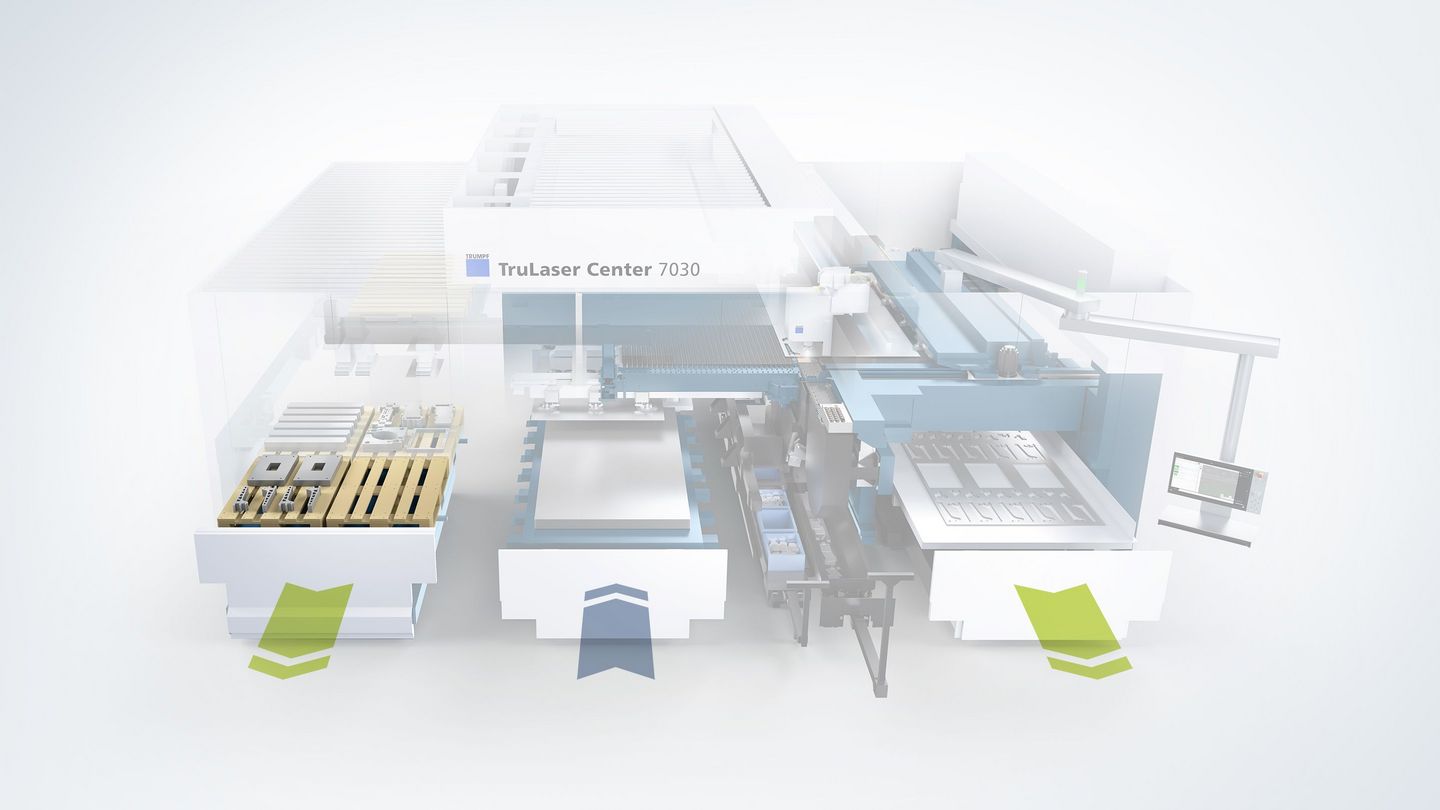

High process reliability or high productivity? The TruLaser Center 7030 resolves this classic decision conflict in laser processing for the very first time. The fully automatic machine takes care of your entire laser processing operations – from the drawing to the sorted part. The machine guarantees reliability through its integrated intelligence, such as the SmartGate, SmartLift, and SortMaster Speed. The novel machine concept with its additional axis and higher-level axis movements provide speed and revolutionary productivity. The perfect interaction of the components makes the machine incomparably economic.

Profitable overall system

Whoever wants to optimize costs with laser cutting must take the whole process into consideration. The TruLaser Center 7030 was created with this objective: it safely and independently takes on all processes related to laser cutting. The advantage for you: Your throughput time and processing costs will be drastically reduced. You get maximum profitability from your laser machining process – from the drawing to the sorted part. The machine takes over monotonous and tedious tasks, saving you costs and time simultaneously.

A comparison of process steps

The result is that the TruLaser Center 7030 takes on all processes related to laser cutting reliably and independently – which significantly lowers your sheet metal processing costs.

All the processing steps integrated in one machine

For a clear explanation, watch these videos to learn how the TruLaser Center 7030 can optimize your production

TruLaser Center 7030. Automated laser cutting, redefined.

Make short work of your laser production.

The TruLaser Center 7030 with storage connection in action.

This is how the revolutionary laser innovation works.

Intelligent innovations: perfectly combined for your success

Discover the machine now!

Highly dynamic cutting

The TruLaser Center 7030 combines revolutionary productivity and dynamics with absolute reliability. The dynamic additional axis, SmartGate, brush tables, SmartLift and SortMaster Speed all contribute to this.

Experience the innovative SmartGate, SmartLift, and SortMaster Speed in action through these animations

Intelligent part support in action.

Experience the fastest and most flexible unloading solution on the market.

Discover the machine now!

Reliable cutting and removal

At the right place, at the right time: before the SmartGate discharges a part, the clever cutting process components ensure that your workpiece cannot tilt. You can also look forward to the fastest and most versatile unloading system on the market.

You can find out more in the following videos

Intelligent part support in action.

Experience the fastest and most flexible unloading solution on the market.

Discover the machine now!

Intelligent processes

Programming is also fully automatic: in one step, TruTops Boost delivers well thought-out suggestions for laser cutting, removing, sorting, and depositing your parts.

You can find out more in the following film

Discover the machine now!

Jetzt Webinar zur TruLaser Center 7030 downloaden

Laden Sie sich jetzt unser kostenloses Online-Webinar herunter und lernen alles, was Sie über die TruLaser Center 7030 wissen müssen.

TruLaser Center 7030: one machine, numerous success stories

Decreasing lot sizes, increasing quality requirements, a safe and efficient production – the challenges with 2D laser cutting are as diverse as the metal-processing industry itself. Three TRUMPF customers with their specific requirements have contributed significantly to the development and optimization of the TruLaser Center 7030. In the success stories, read how these customers produce more quickly, flexibly and efficiently with this machine.