Solutions

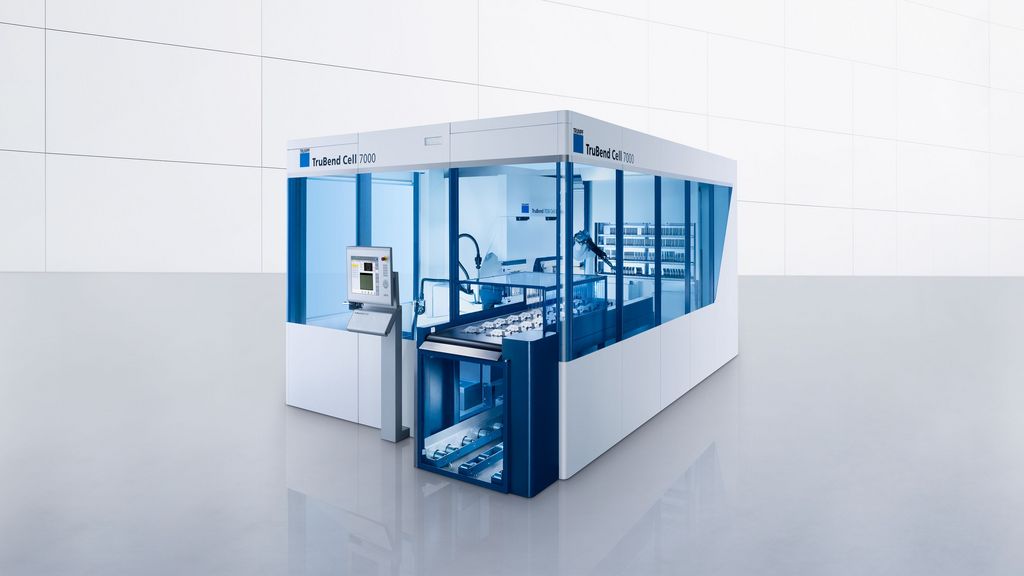

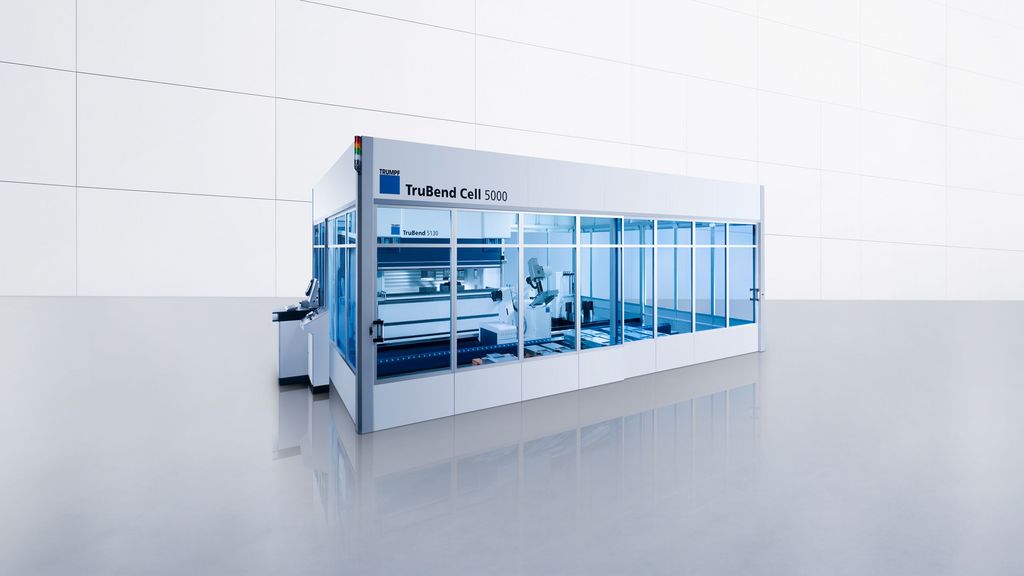

"TRUMPF is an important partner and has been supporting us in automating our production since as early as 2006," says Alessandro Cini. At that time, the collaboration began with the purchase of a TruLaser 3030 fiber. Since then, the two companies have been in close contact, including via the TRUMPF Service App. 5 years ago, AEC Illuminazione decided to replace the old bending cells with new automated ones. "We decided on TRUMPF right away because we knew that the machines are easy to operate and could be easily integrated into our production," says Cini. "With the TruBend Cell 7000 and the larger TruBend Cell 5000, we then found two machines that matched our requirements exactly." One of the main advantages for the company is the ability to bend different materials. After all, AEC Illuminazione is the only manufacturer on the market that also produces reflectors made of aluminum. In addition, the TruBend Cell 5000 can take over the work of the TruBend Cell 7000. This makes the company fast and flexible even during production peaks, large orders and special customer requests. In addition, both machines can be directly linked to the technical design department, where products and components are designed on computers. This significantly shortens the path from idea to design to finished product.

Implementation

In recent years, AEC Illuminazione has automated nearly all of its production for greater efficiency and higher production volume. With TRUMPF's bending cells, the important bending processes for components such as aluminum reflectors, lighting brackets and covers run much faster and with a consistently high quality. After all, once set, the TruBend Cell 5000 and TruBend Cell 7000 always run the same program with the same precision. "We could never have afforded that manually," says CEO Alessandro Cini. In addition, the bending cells result in significantly fewer production errors and optimal utilization of resources thanks to intelligent material planning. "This gives us full control over the entire process and allows us to view the production status at any time," says Cini. "This was particularly important to us in order to identify further potential for improvement in our production chain."