Solutions

By automating processes, the 3D Programming Tube software makes programming tube-cutting machines easier and safer in many respects. When programming a thread in the pasty, for example, programmers had to specify holes individually for each one by clicking with the mouse and then they had to select the suitable tool combination. Then the correct processing sequence had to be specified to prevent collisions. Using the thread parameters, the new Programming Tube software creates the NC program automatically, including all required tools and the processing sequence.

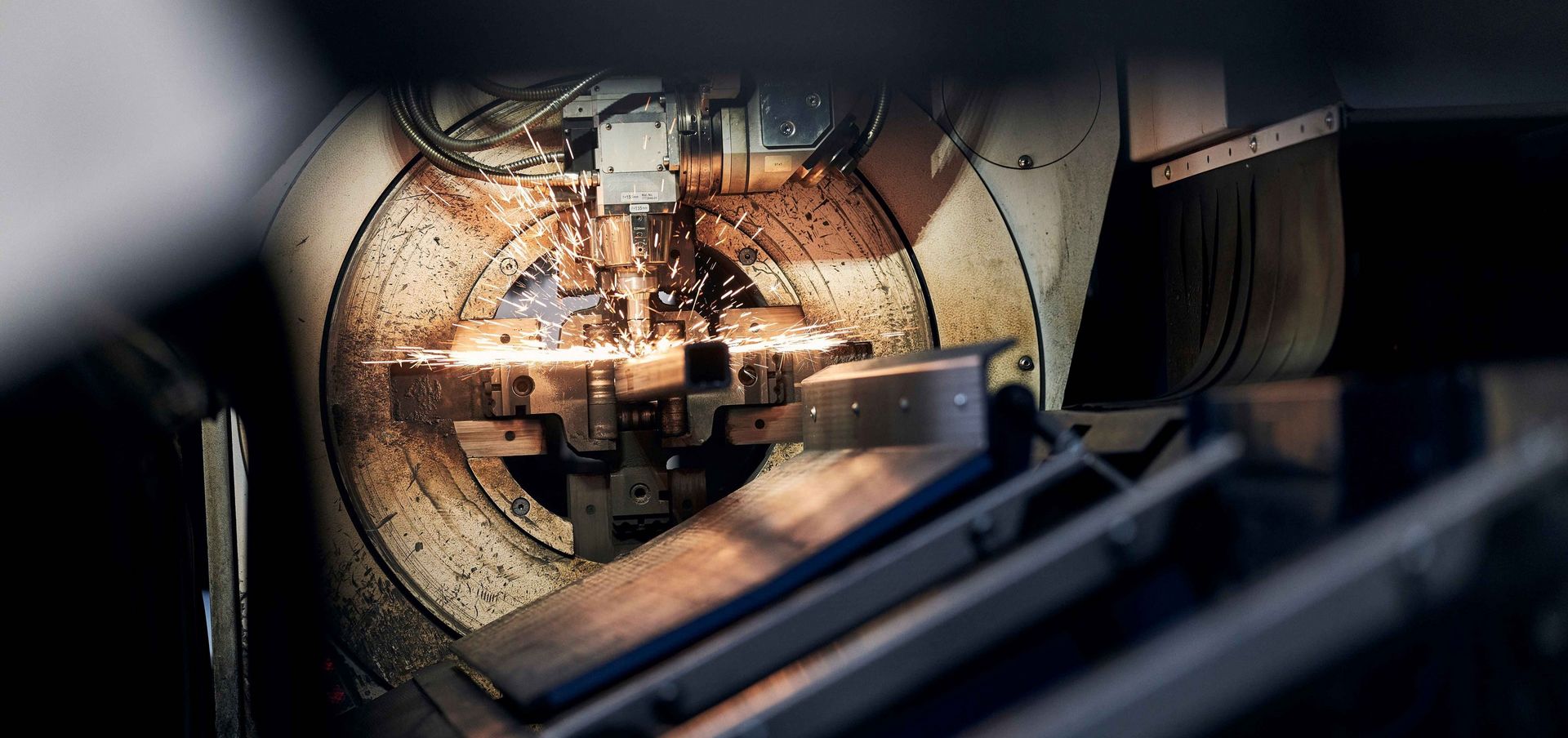

The interaction between Tube Design, Programming Tube and processing on the machine also works perfectly now. Programming Tube creates NC programs automatically based on the 3D CAD design in Tube Design. Production at the machine then runs up to 99% without manual interventions. If changes do need to be made to the design, Programming Tube does this automatically.

The Programming Tube also sets new standards in terms of operator convenience: By editing directly, the programmer can move the object to the desired position and then ensure that processing is error-free with an automatic simulation. The program corrects incorrect data and rounding radii. Positioning aids and bend connections can be pasted with only a few clicks. Janetzki: "Automatic specification of processing sequences, the improved loading and unloading strategies as well as the simplified programming of special profiles are the cornerstones of this new software. We can use it to program our components quickly and safely so that they exit the machine error-free."

Implementation

"During the test period we were in close contact with software developers from TRUMPF", says Stefan Janetzki, and adds: "Our input from the daily work routine was important for TRUMPF and I think we all benefited and learned a lot during the test run. It was fun to watch the software change over time and see how it continued to improve."